Preparation method of high-nickel ternary positive electrode material for lithium ion battery

A lithium-ion battery and cathode material technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as unfavorable production of high-nickel cathode materials, easy corrosion and cracking of coatings, etc., to improve product quality, reduce Corrosive, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

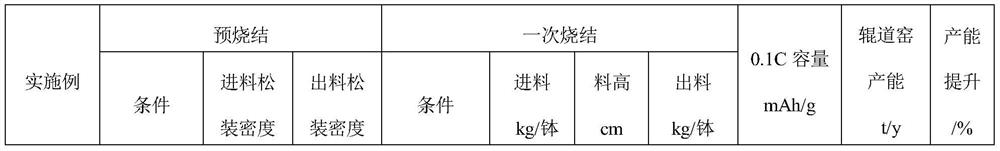

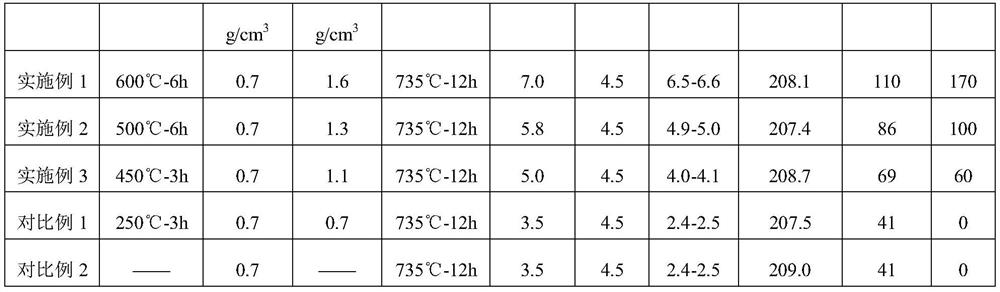

Embodiment 1

[0022] 1) 20kg NCA precursor Ni 0.87 co 0.1 al 0.03 (OH) 2 , 9.7kg lithium hydroxide, 100g TiO 2 Join in the high-speed stirring mixer, stir at 300rpm for 15min, then stir at 600rpm for 30min to obtain a high-mixture;

[0023] 2) Add the high-grade mixture into the rotary kiln at a uniform speed for pre-sintering. The sintering temperature is 600°C, the time is 6 hours, the atmosphere is pure oxygen, and the air flow is 500L / min to obtain pre-sintered materials with a bulk density of 1.6-1.8g / min. cm 3 ;

[0024] 3) The pre-sintered material is sintered once in a 10-meter atmosphere roller kiln, the amount of sagger is 7kg / bowl, the filling height is ≈4.5cm, the sintering temperature is 735°C, the time is 12h, and the sintering atmosphere is pure oxygen atmosphere , the oxygen ventilation rate is 1000L / min, and the primary sintered material is obtained, and the amount of discharging bowl is 6.5-6.6kg / bowl;

[0025] 4) Grind the primary sintered material, control D50 at ...

Embodiment 2

[0029] 1) 20kg NCA precursor Ni 0.87 co 0.1 al 0.03 (OH) 2 , 9.7kg lithium hydroxide, 100g TiO 2 Join in the high-speed stirring mixer, stir at 300rpm for 15min, then stir at 600rpm for 30min to obtain a high-mixture;

[0030] 2) Put the high-mixed material into the rotary kiln at a uniform speed for pre-sintering. The sintering temperature is 500°C, the time is 6 hours, the atmosphere is pure oxygen, and the air flow is 500L / min to obtain pre-sintered materials. cm 3 ;

[0031] 3) Sinter the pre-sintered material once in a 10-meter atmosphere roller kiln. The sagger filling capacity is 5.8-5.9kg / bowl, the filling height is ≈4.5cm, the temperature is 735°C, the time is 12h, and the sintering atmosphere is pure Oxygen atmosphere, the oxygen ventilation rate is 1000L / min, and the primary sintered material is obtained, and the amount of discharging material is 4.9-5.0kg / bowl;

[0032] 4) Grind the primary sintered material, control D50 at 13.0±2.0μm, control D90 at 24.0±2....

Embodiment 3

[0036] 1) 20kg NCA precursor Ni 0.87 co 0.1 Al 0.03 (OH) 2 , 9.7kg lithium hydroxide, 100g TiO 2 Join in the high-speed stirring mixer, stir at 300rpm for 15min, then stir at 600rpm for 30min to obtain a high-mixture;

[0037] 2) Put the high-grade mixture into the rotary kiln at a uniform speed for pre-sintering, the temperature is 450°C, the time is 3 hours, the atmosphere is pure oxygen, the air flow is 500L / min, and the pre-sintering material is obtained, the bulk density is 0.9-1.0g / cm 3 ;

[0038] 3) The pre-sintered material is sintered once in a 10-meter atmosphere roller kiln. The sagger capacity is 4.4kg / bowl, the filling height is ≈4.5cm, the temperature is 735°C, the time is 12h, and the sintering atmosphere is pure oxygen atmosphere. , the oxygen ventilation rate is 1000L / min, and the primary sintered material is obtained, and the amount of discharging material is 3.3-3.4kg / bowl;

[0039] 4) The primary sintered material is pulverized, and the D50 is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com