Automatic elastic band threading machine for covers

A rubber band machine and cover technology, which is applied in the field of cover binding, can solve the problems of low production efficiency, unsightly appearance, and increased labor intensity of workers, and achieve the effect of improving production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

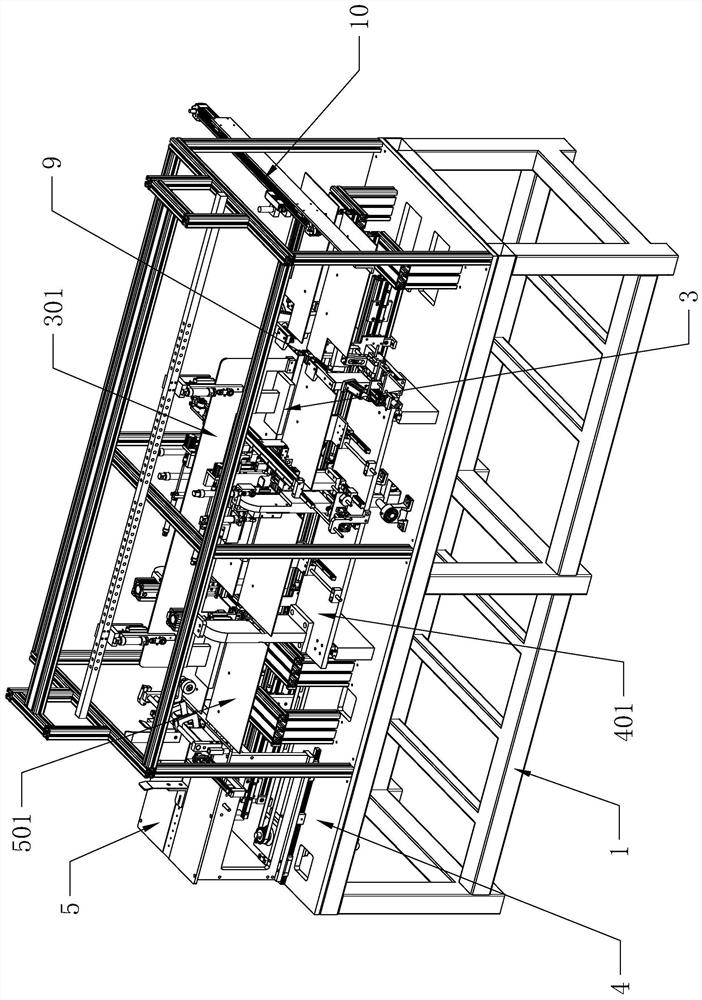

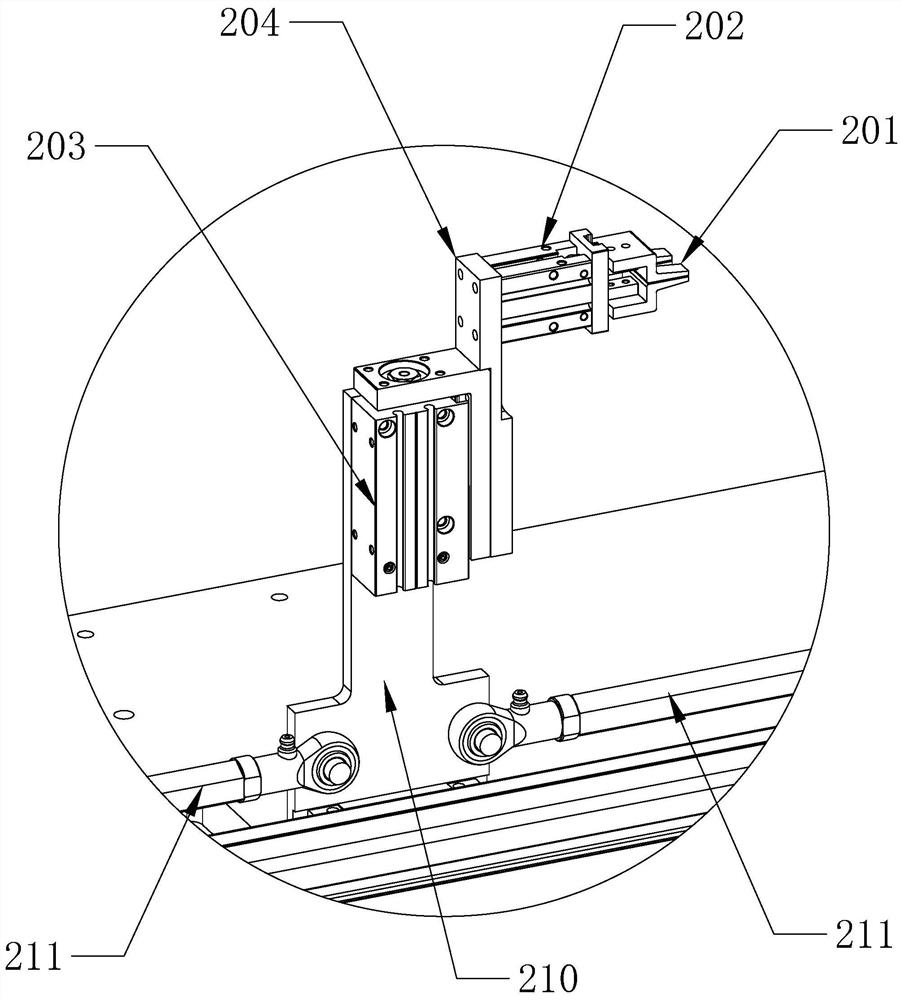

[0043] like figure 1 As shown, a kind of automatic cover piercing machine of the present invention includes a frame 1 and a feeding device, a punching device, a belt threading device, and a gluing device arranged on the frame 1 in sequence. There is a conveying device for conveying the cover. Under the conveyance of the conveying device, the cover passes through the punching device, the belt threading device, and the gluing device in turn from the feeding device, and can correspondingly complete grabbing a cover, punching holes on the cover, punching The two ends of the rubber band and the rubber band are glued into the hole and fixed with the cover. An output device is also provided on the frame 1 for transferring the glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com