Batching method of lithium ion battery positive electrode slurry

A technology for lithium ion battery and positive electrode slurry, applied in the field of lithium ion battery, can solve the problems such as the large weight difference between the active material and the conductive agent and other auxiliary materials, the agglomeration of the conductive agent particles is not easy to disperse, and the energy consumption in the kneading process is large. Eliminate the viscosity adjustment process, reduce the difficulty of the batching process, and accelerate the effect of wetting and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The ratio of the positive electrode slurry formula is: ternary material NCM111: super-P: CNT (5% solid content slurry): PVDF=95%: 2%: 1%: 2%; the solvent is NMP, and the positive electrode slurry The solid content is 67%.

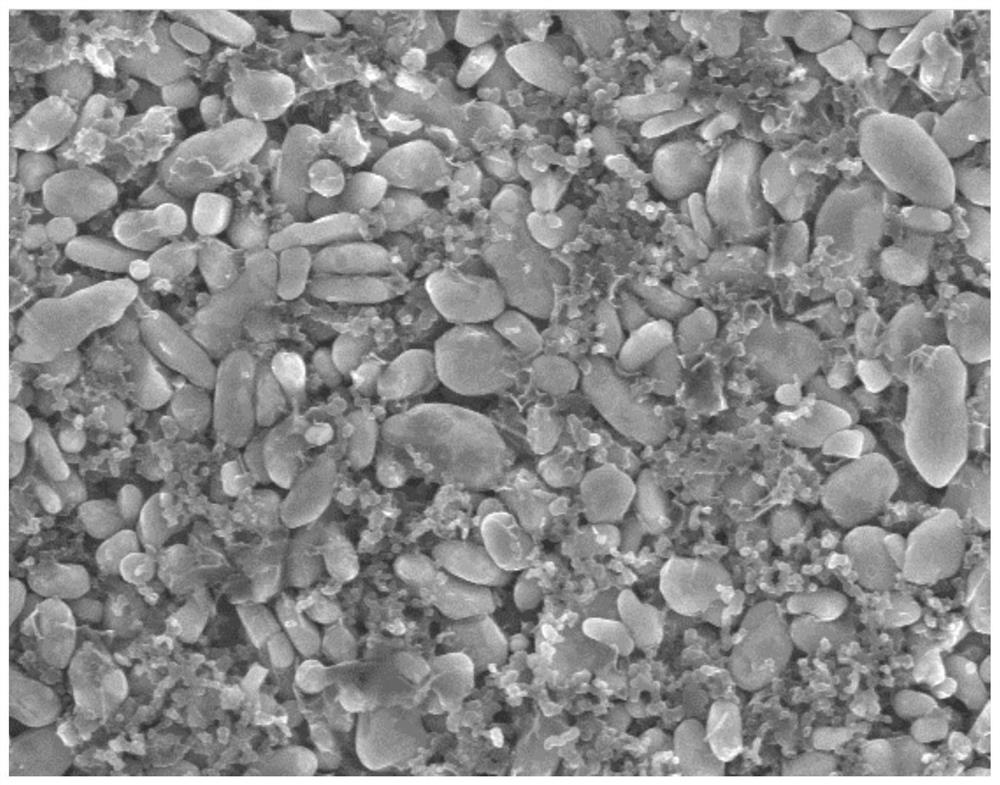

[0038] (1) Put the ternary material NCM111 with a D50 particle size of 5 μm and the conductive carbon black super-P with a formula content of 30% into the mechanical fusion machine, and quickly premix and disperse for 30 minutes at a speed of 1500 rpm to obtain a premix Composite material;

[0039] (2) Add PVDF 6020 into the planetary mixer according to the positive electrode formula, add NMP according to the ratio of PVDF:NMP=7:93, start the revolution and the rotation of the dispersion disc, the revolution speed of the planetary mixer is 25 rpm and disperse The rotation speed of the disc is 1200 rpm, and after stirring for 4 hours, PVDF glue is obtained; add the remaining 70% conductive carbon black super-P and CNT slurry to the glue, turn on the ...

Embodiment 2

[0044] The formula ratio of positive electrode slurry is: ternary NCM523: lithium manganese oxide: super-P: ECP (10% solid content slurry): PVDF=66.15%: 28.35%: 2%: 1.5%: 2%; solvent is NMP , the solid content of the positive electrode slurry was 68.5%.

[0045] (1) Put the ternary material NCM523 with a D50 particle size of 4 μm, lithium manganate with a D50 of 10 μm, and conductive carbon black super-P with a formula ratio of 30% into the mechanical fusion machine, and quickly premix and disperse for 30 minutes to obtain premixed materials;

[0046] (2) Add PVDF 5120 according to the positive electrode formula into the planetary mixer, add NMP according to the ratio of PVDF:NMP=7:93, turn on the revolution and the rotation of the dispersing disc, and get PVDF glue after stirring for 4 hours; Add the remaining 70% conductive carbon black super-P and ECP slurry, turn on the revolution at 10 rpm and stir slowly for 20 minutes, adjust the revolution at 30 rpm, disperse at 1500 ...

Embodiment 3

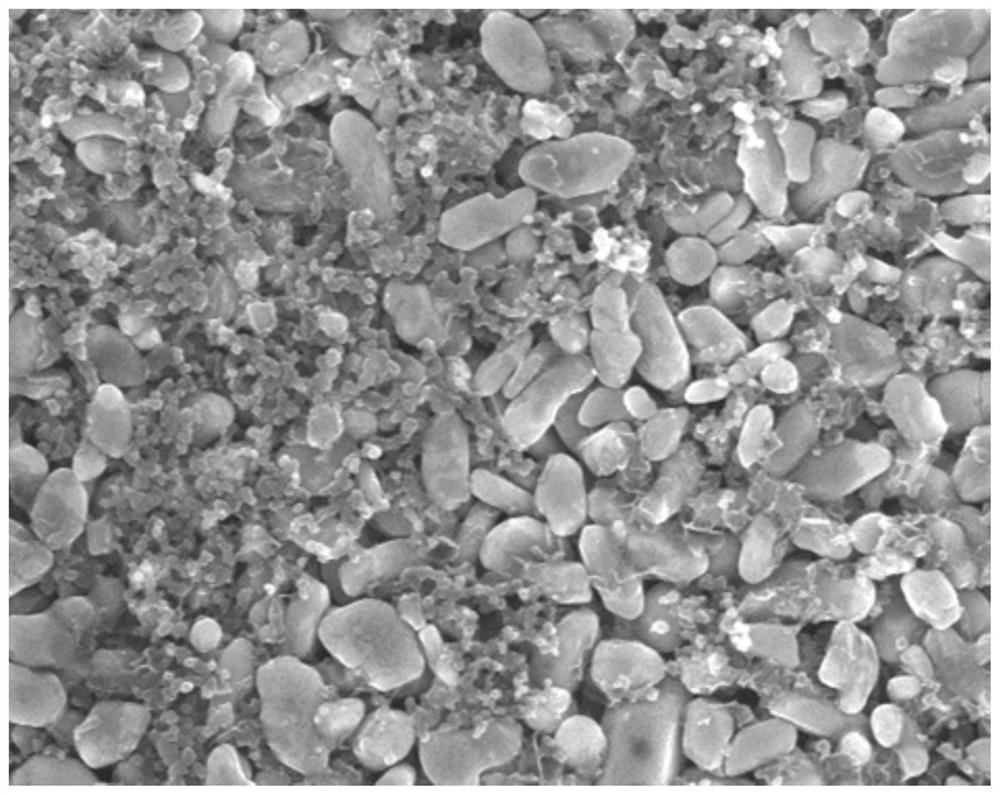

[0051] The positive electrode slurry formula ratio is: lithium iron phosphate LFP: super-P: graphene (slurry with a solid content of 5%): PVDF=93%: 3.5%: 1.5%: 2%; the solvent is NMP, and the positive electrode The solid content of the slurry was 50%.

[0052] (1) Add lithium iron phosphate LFP with a D50 of 0.4 μm, conductive agent A super-P and PVDF into an intensive mixer, and mix for 5 minutes to obtain a premix;

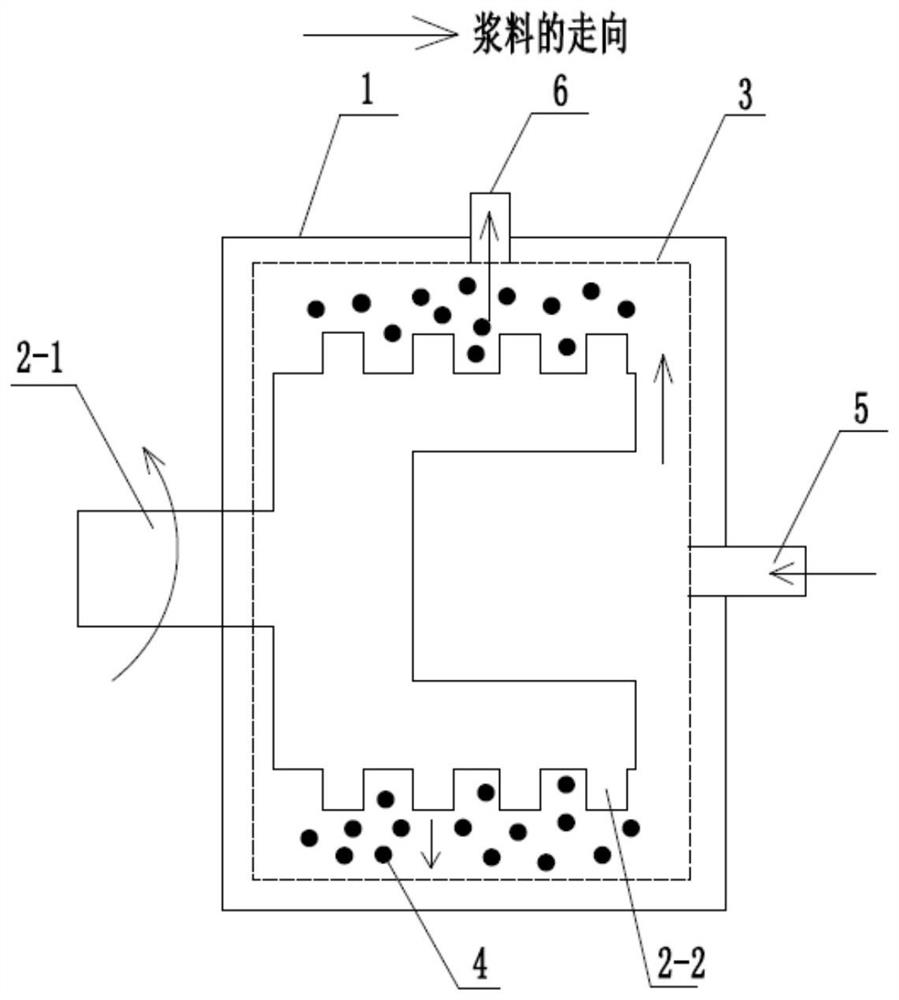

[0053] (2) Add the conductive agent B graphene slurry and NMP into the double planetary mixer, turn on the revolution speed of the mixer at 25 rpm, disperse at 800 rpm, and slowly add the above premix through the upper feeding port of the mixer;

[0054] (3) After adding the premix, adjust the revolution speed to 45 rpm, disperse at 1200 rpm, stir at high speed for 60 minutes, and then vacuumize and stir for 90 minutes;

[0055] (4) Finally, put the slurry in step 3 into the continuous grinding and dispersing machine through the pipeline and grind it for 4 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com