Konjak recombinant rice with low glycemic index and preparation method of konjak recombinant rice

A technology of reconstituted rice and low blood sugar, which is applied in the directions of food ingredients, food forming, and function of food ingredients, etc., can solve the problems of poor sensory quality, poor chewiness of reconstituted rice, and inability to cook reconstituted rice, and achieves a low glycemic index. , delaying digestion and absorption, the effect of excellent sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

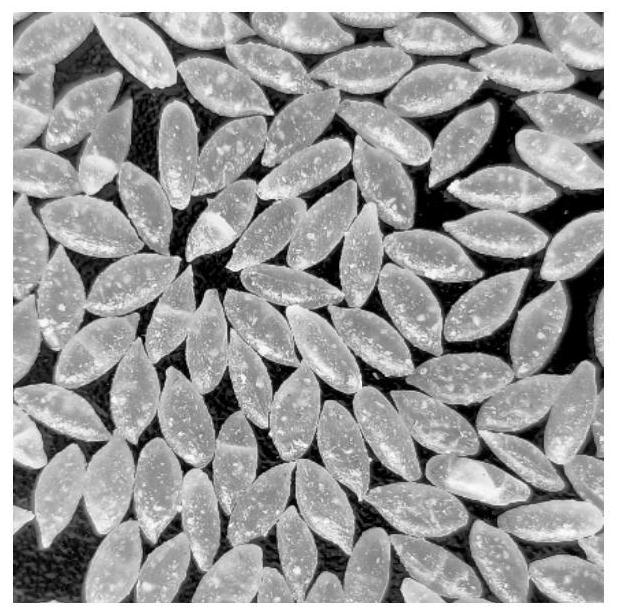

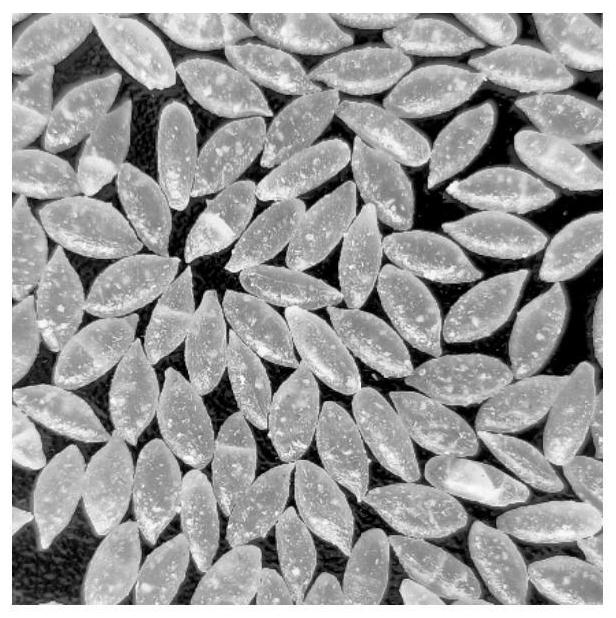

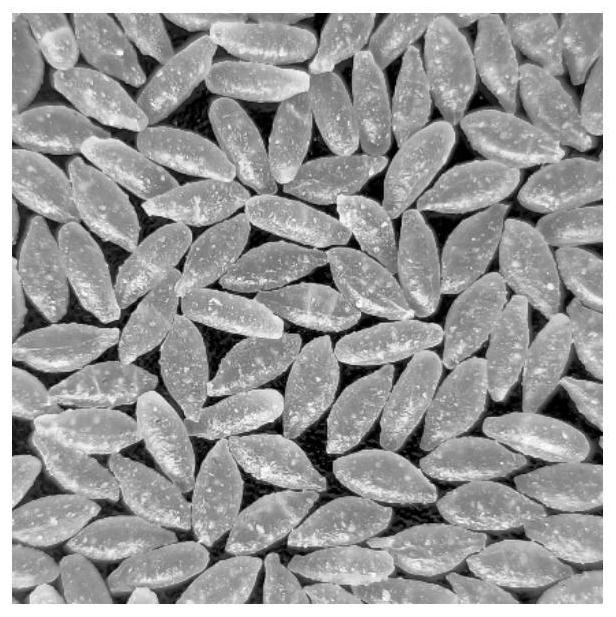

Image

Examples

Embodiment 1

[0041] Example 1 Low glycemic index konjac recombined rice

[0042] 1. Raw materials

[0043] The present embodiment provides a series of low glycemic index konjac recombined rice, selected indica rice, naked oats, chickpea and purified konjac micropowder (purity is more than 95%) as the main raw material of low glycemic index konjac rice, listed in table 1 There are basic nutrient content and GI value (low glycemic index) of 4 raw materials.

[0044] Table 1 Basic nutrient composition and GI of raw materials (based on 100g edible portion)

[0045]

[0046] Note: The molecular weight of purified konjac powder is 8×10 4 ~1.5×10 6 . *Glucose is used as a reference; **According to the definition of GI, purified konjac powder will not increase the blood sugar level of the human body, so the GI value of purified konjac powder cannot be calculated.

[0047] 2. Each recombined rice (100g) is composed of each component of the weight shown in Table 2.

[0048] Table 2 15 formu...

Embodiment 2

[0056] Example 2 Determination of Konjac Recombined Rice In Vitro Glycemic Index

[0057] 1. Experimental method

[0058] The glycemic index of the 15 kinds of recombinant rice prepared in Example 1 was tested by the test of simulating starch digestion in vitro. Take 100mg of sample and 10 glass beads in a 50mL centrifuge tube + 1mL of third-grade water: boil in a water bath for 10 minutes, then cool to room temperature with running water; add 4mL of 0.5M pH 5.2 sodium acetate buffer, and shake at 37°C and 180rpm for 10 minutes; Add 3mL α-amylase, glucoamylase, trypsin mixed enzyme solution; 37 ℃ 180rpm shaker, take 0.2mL digestion solution at 0min, 20min, 40min, 60min, 80min, 100min, 120min, 180min, and quickly in 0.8mL without Inactivate the enzyme in water and ethanol, centrifuge at 14,500 rcf for 3 min; take 0.5 mL of the supernatant and use the DNS method to measure the reducing sugar.

[0059] The starch hydrolysis curve is drawn with the starch hydrolysis rate as the ...

Embodiment 3

[0064] Example 3 Determination of Glycemic Index in Konjac Recombined Rice

[0065] In order to further verify the glycemic index of the recombinant rice obtained in Example 1 (taking No. 13 as an example), follow the requirements of WS / T652-2019, and use in vivo experiments for further verification. Choose 10 healthy young students as subjects, young 22-25 years old, body mass index 18.5-23.9kg / m 2 , No metabolic disease, no family history of diabetes and other metabolic diseases.

[0066] 1. Oral glucose tolerance test

[0067] The subjects were fasted for 10 hours to measure the fasting blood glucose level, choose pure glucose powder (50g per person) as a reference, dissolve it in 200mL of warm water and drink it within 5 minutes, and then drink it at 15, 30, 45, 60, 90, 120min to measure the blood sugar level.

[0068] 2. Food glucose tolerance test

[0069] Those who pass the glucose tolerance can participate in the food blood glucose tolerance test. After measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com