Ternary positive electrode material and preparation method thereof, lithium ion battery and electric equipment

A cathode material, lithium source technology, applied in the field of lithium ion batteries and electrical equipment, ternary cathode materials and their preparation, can solve the problems of affecting the electrochemical performance of the material, not having electrochemical activity, affecting the specific capacity of the material, etc. Achieve excellent electrochemical activity, better coating effect, and improve cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062]S1: According to the molar ratio of 1:1.12, take Ni0.6Co0.2Mn0.2(OH)2Precursor and Li2CO3Mix well in the high mixer;

[0063]S2: The mixture obtained from S1 is heated to 650°C and kept for 4 hours in an air atmosphere in an atmosphere furnace, and then heated to 900°C for 14 hours at a heating rate of 3°C / min, and the base material is obtained after cooling down;

[0064]S3: Take the doped amorphous coating agent Ni with D50=300nm0.3Co0.3Mn0.3Al0.1(OH)2, It is uniformly mixed with the base material obtained in S2, wherein the mass of the doped amorphous coating agent is 5% of the mass of the base material;

[0065]S4: Heat the mixture obtained in S3 in an atmosphere furnace in an air atmosphere to 600° C. and keep it for 6 hours at a heating rate of 5° C. / min. After cooling, a high-performance double-coated ternary cathode material is obtained.

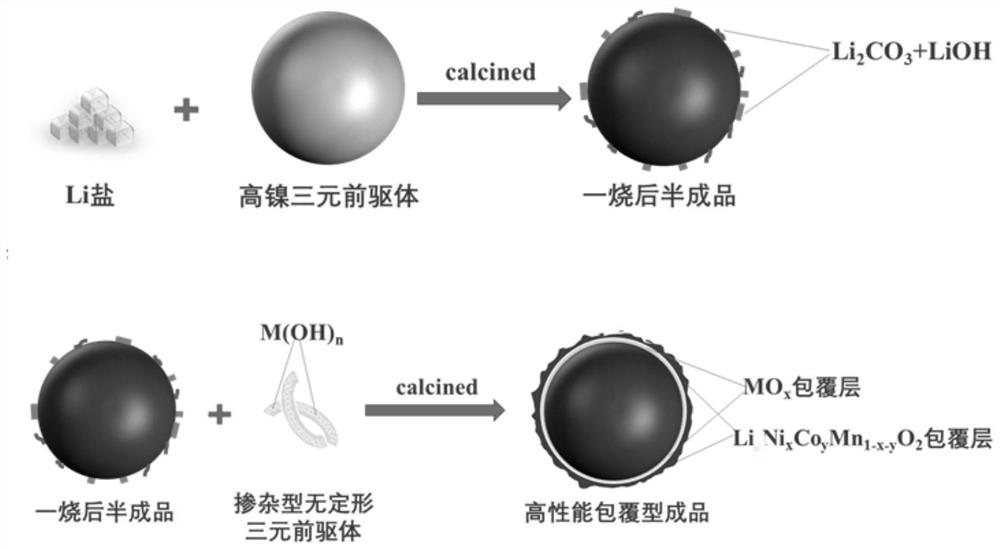

[0066]The reaction process is likefigure 1 Shown.

Embodiment 2

[0068]S1: According to the molar ratio of 1:1.12, take Ni0.8Co0.1Mn0.1(OH)2Precursor and LiOH·H2O is evenly mixed in the high mixer;

[0069]S2: Heat the mixture obtained from S1 in an atmosphere furnace in an oxygen atmosphere to 500°C and hold it for 4h, then heat it to 810°C, hold it for 14h, at a heating rate of 3°C / min, and obtain the base material after cooling down;

[0070]S3: Take the doped amorphous coating agent Ni with D50=300nm0.3Co0.3Mn0.3Al0.1(OH)2, It is uniformly mixed with the base material obtained in S2, wherein the mass of the doped amorphous coating agent is 5% of the mass of the base material;

[0071]S4: Heat the mixture obtained from S3 in an atmosphere furnace in an oxygen atmosphere to 600°C and keep it for 6 hours at a heating rate of 5°C / min. After cooling, a high-performance double-coated ternary cathode material is obtained.

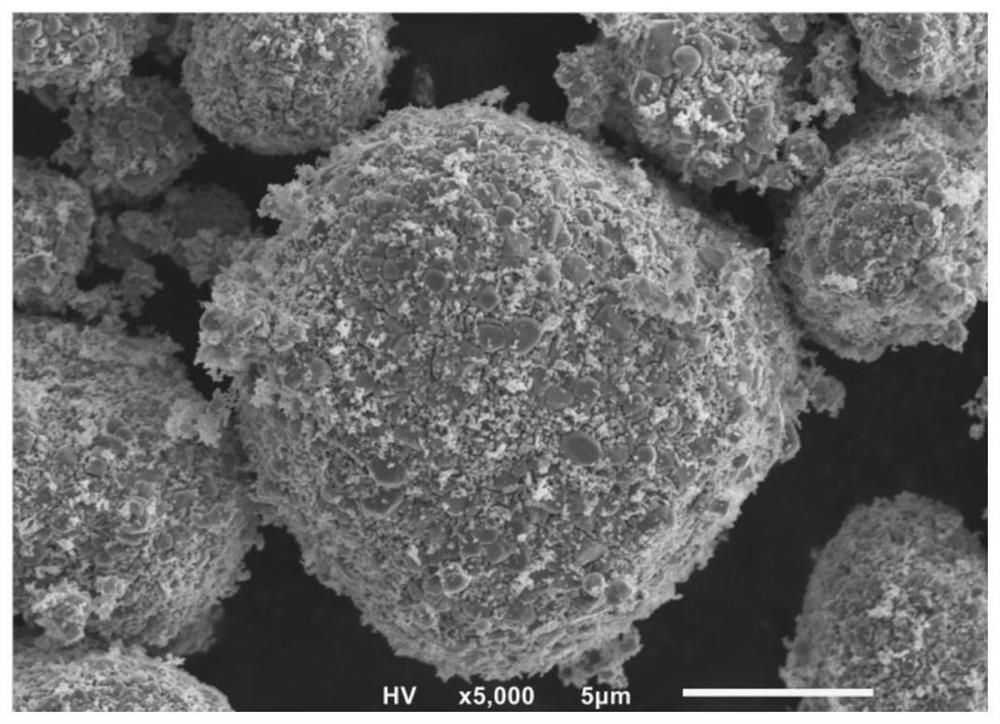

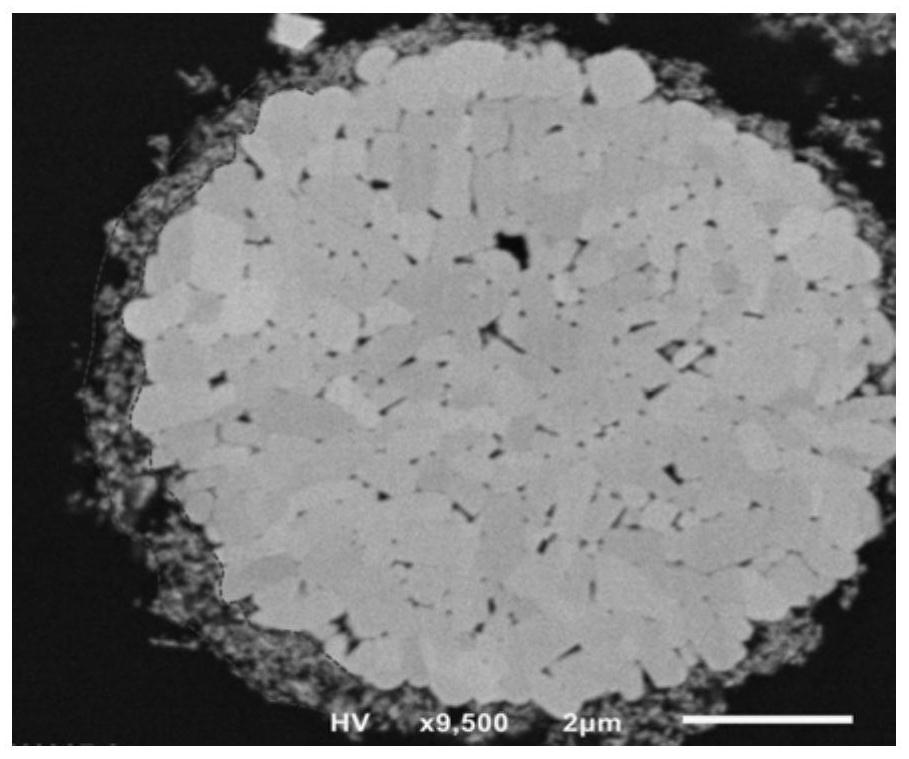

[0072]The SEM image of the prepared high-performance double-coated ternary cathode material is as followsfigure 2 Shown. The SEM image of i...

Embodiment 3

[0074]S1: According to the molar ratio of 1:1.12, take Ni0.8Co0.1Mn0.1(OH)2Precursor and LiOH·H2O is evenly mixed in the high mixer;

[0075]S2: Heat the mixture obtained from S1 in an atmosphere furnace in an oxygen atmosphere to 500°C and hold it for 4h, then heat it to 810°C, hold it for 14h, at a heating rate of 3°C / min, and obtain the base material after cooling down;

[0076]S3: Take the doped amorphous coating agent Ni with D50=300nm0.3Co0.3Mn0.3Al0.1(OH)2, It is uniformly mixed with the base material obtained in S2, wherein the mass of the doped amorphous coating agent is 10% of the mass of the base material;

[0077]S4: Heat the mixture obtained in S3 in an atmosphere furnace in an oxygen atmosphere to 600° C. and keep it for 6 hours at a heating rate of 10° C. / min. After cooling, a high-performance double-coated ternary cathode material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com