Battery separator, preparation method thereof and lithium ion battery

A battery separator and separator technology, used in secondary batteries, battery pack components, circuits, etc., can solve problems such as adverse effects on battery quality, side reactions of chemical components, affecting battery quality, etc., to achieve good safety, reduce The effect of wrinkling and suppressing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

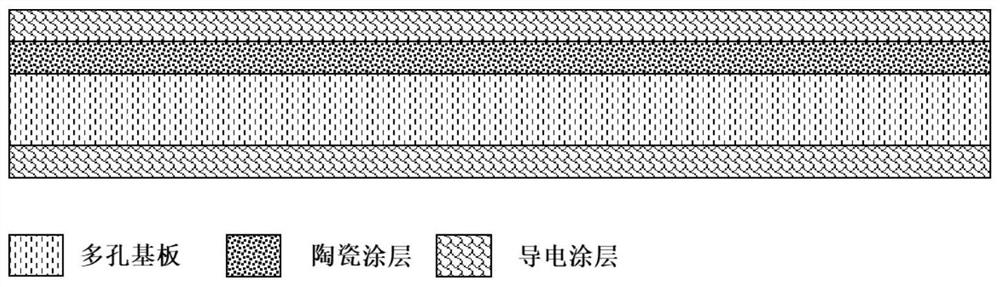

[0048] Such as figure 1 As shown, the battery separator provided in this embodiment (hereinafter referred to as the composite porous separator) includes a porous polymer substrate, a ceramic coating (about 2 μm in thickness) coated on one surface of the porous polymer substrate, coated on the porous polymer A conductive coating (about 1 μm in thickness) on the other surface of the substrate and a conductive coating (about 1 μm in thickness) coated on the surface of the ceramic coating; wherein, such as figure 2 with image 3 As shown, the shape of the conductive material in the conductive coating is one-dimensional, so as to build a conductive network; the content of the conductive material in the conductive coating is about 1.34%.

[0049] The battery provided in this example is formed by using the above-mentioned composite porous separator.

[0050] The electrical composite porous separator of this embodiment and the battery formed by using the separator are specifically ...

Embodiment 2

[0065]The difference between the battery separator provided in this example and the battery formed by using the separator and Example 1 is that the addition amount (ie content) of the conductive material in the conductive coating is about 0.89%;

[0066] The difference in the corresponding preparation process is only that: in step 1, the mass ratio of polyvinylidene fluoride to carbon nanotubes is 1:0.0090.

Embodiment 3

[0068] The difference between the battery separator provided in this example and the battery formed using the separator and Example 1 is that the amount of conductive material added in the conductive coating is about 0.45%;

[0069] The difference in the corresponding preparation process is only that: in step 1, the mass ratio of polyvinylidene fluoride to carbon nanotubes is 1:0.0045.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com