Manufacturing method of thermopile sensor

A technology for thermopile sensors and manufacturing methods, which is applied in the field of manufacturing thermopile sensors, can solve problems such as device precision needs to be improved, and achieve the effects of reducing process costs, simplifying process flows, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

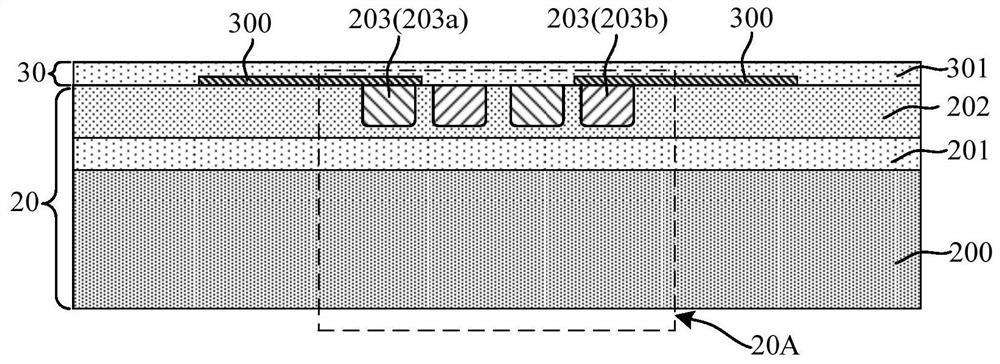

[0013] It can be known from the background art that the device precision of the existing thermopile sensor needs to be improved.

[0014] Thermopile sensors are also called thermopile infrared detectors. Traditional thermopile sensors deposit polysilicon or metal on a dielectric film to make thermocouples to sense temperature information, and then use the method of anisotropic wet etching of silicon on the back A thermal insulation cavity is formed under the dielectric film to increase thermal resistance, and the thermocouple pair is electrically connected to the circuit structure on the side of the thermocouple pair, so as to realize the transmission of induction signals. However, there is no substrate under the device formed by this method for sealing, and the heat in the heat-insulating cavity will still be lost in a certain form, resulting in low measurement accuracy of the thermopile sensor.

[0015] In order to solve the above-mentioned technical problem, the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com