Defect detection method, storage medium and device for radiographic image weld area

A technology of regional defects and detection methods, which is applied in image analysis, image enhancement, image data processing, etc., can solve the problems of low false alarm rate, high defect detection rate, and difficulty in extraction, and achieve low false alarm rate and high defect detection The effect of rate and convenient classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

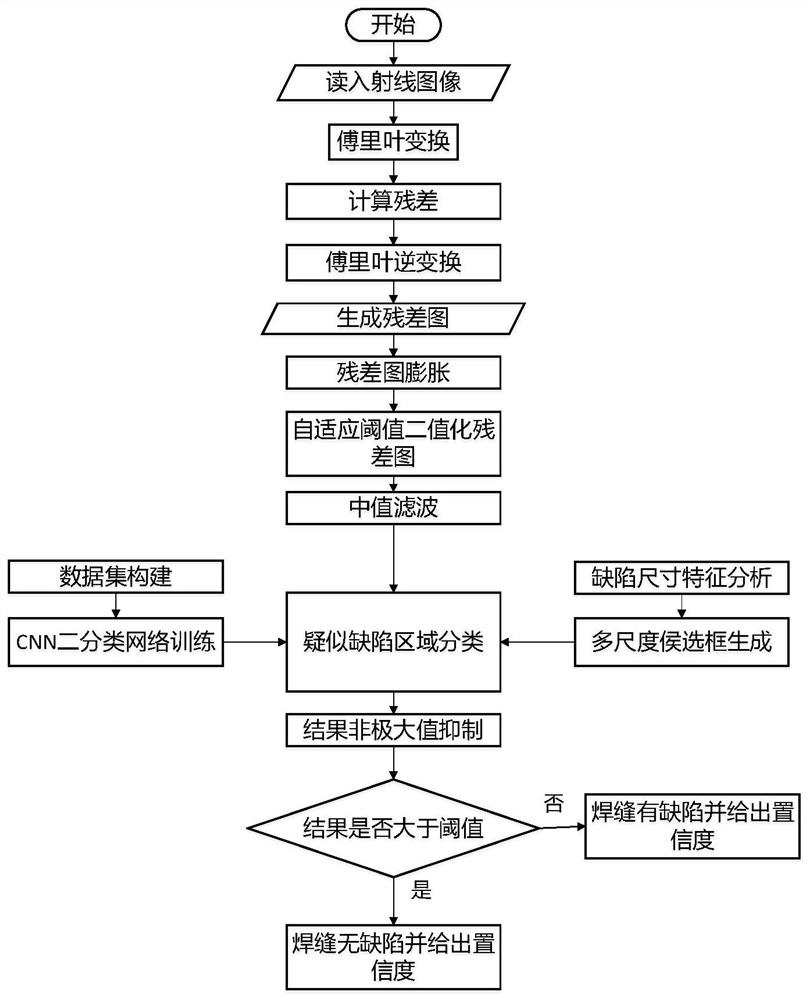

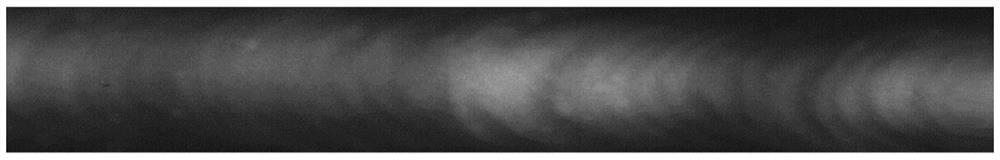

[0063] The invention provides a method for detecting whether there is a defect in the weld area of a radiographic image based on the background characteristics, generates a residual map for the weld image, detects suspected defect areas based on the residual map, and generates a multi-scale candidate frame based on the suspected defect area , input the candidate frame to the CNN network for classification, judge whether the weld picture contains defects according to the classification results, and quickly detect the defect area in the weld image with low contrast, complex background, and low representation of small target area features and give Confidence, so as to quickly and accurately detect defect-free weld pictures.

[0064] see figure 1 , the present invention is a method for detecting whether there is a defect in a radiographic weld area based on background characteristics, generating a residual map based on the background characteristic, and performing suspected defe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com