Electrostatic atomization chemical vapor deposition gallium oxide film system

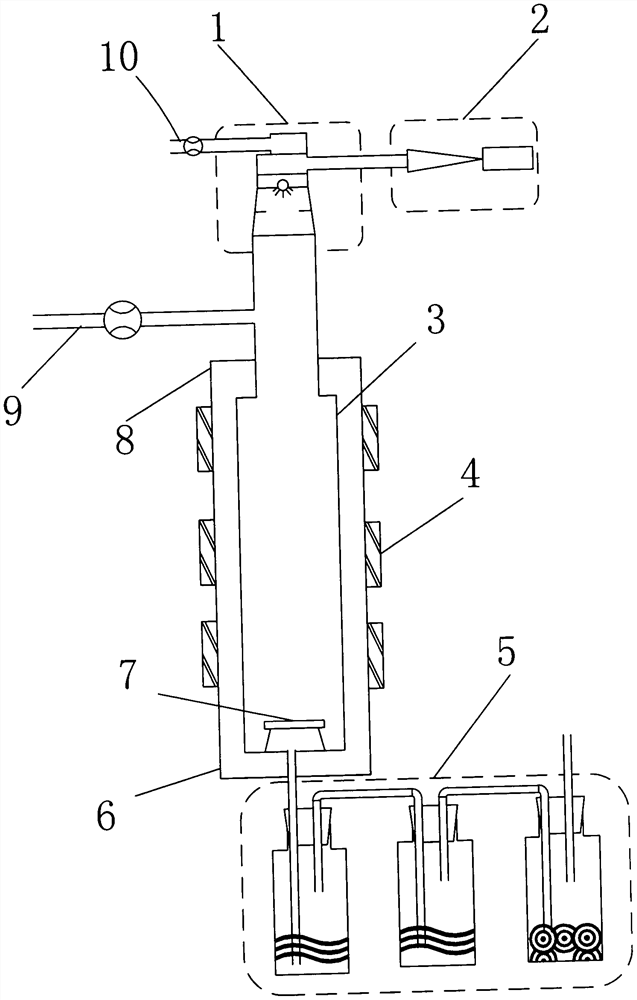

A technology of chemical vapor deposition and electrostatic atomization, which is applied in the field of material growth of chemical vapor deposition, and can solve the problems of epitaxial growth of various crystalline gallium oxide films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Epitaxial α-phase gallium oxide on a glass substrate

[0021] 1. Substrate cleaning

[0022] Specifically, substrate cleaning includes the following steps:

[0023] Put the glass substrate into an ultrasonic cleaner containing cleaning solution, and ultrasonically clean it for 1 min.

[0024] Take out the glass substrate and use nitrogen gas to blow dry the residual cleaning solution on the surface of the glass substrate.

[0025] 2. Select a suitable quartz base according to the size of the substrate, place the glass substrate horizontally on the glass base, and then place it on the bottom of the reaction chamber.

[0026] 3. Growth of α-phase gallium oxide epitaxial layer

[0027] Specifically, the growth of the α-phase gallium oxide epitaxial layer includes the following steps:

[0028] Use nitrogen to evacuate the residual gas in the reaction chamber.

[0029] Reaction chamber temperature setting and preheating, the reaction chamber temperature is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com