Method for preparing aluminum oxide-based composite biological ceramic material through in-situ reaction, and product prepared by method

A composite bioceramic and alumina-based technology, applied in the field of medical biomaterials, can solve the problems of difficult uniform dispersion of liquid phase and seed crystals, low molding density, poor bonding performance, etc., to avoid brittle transcrystalline plane fracture, mechanical The effect of excellent performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

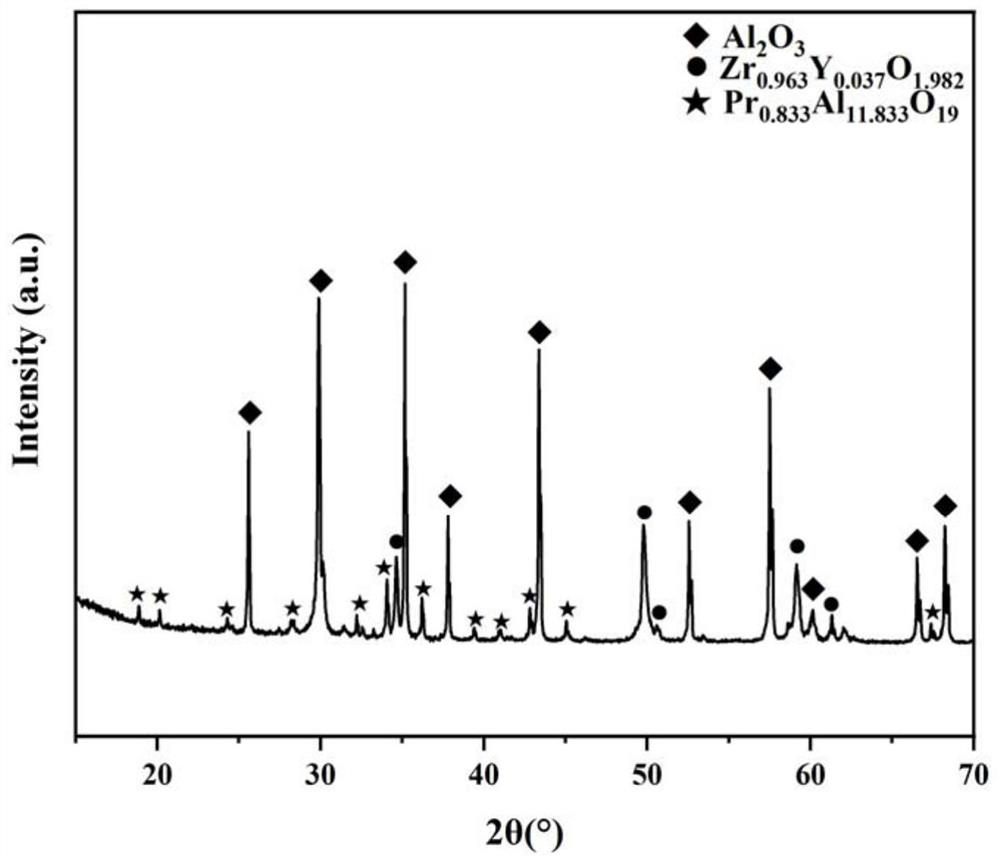

[0028] In this embodiment, a method for preparing an alumina-based composite bioceramic material by in-situ reaction, the steps are as follows:

[0029] (1) Weigh 89g alumina, 10g 3mol% Y 2 o 3 Stabilized zirconia, 1 g of praseodymium nitrate, and 0.89 g of polyacrylic acid were added to a planetary ball mill tank at a speed of 300 r / min for 8 hours with 50 mL of absolute ethanol as the medium to obtain a precursor slurry;

[0030] (2) Pour the above-mentioned precursor slurry into a rotary evaporating dryer and continue to heat and spin-dry at a water bath temperature of 60°C for 2 hours, then pass through a 100-mesh sieve to obtain a precursor powder;

[0031] (3) The above-mentioned precursor powder is granulated with a polyvinyl alcohol aqueous solution having a concentration of 5% (the amount of polyvinyl alcohol is 0.5 wt% of the mixed powder), and then dry-pressed under a pressure of 20 MPa to obtain a ceramic green body;

[0032] (4) The above-mentioned ceramic green...

Embodiment 2

[0034] In this embodiment, a method for preparing an alumina-based composite bioceramic material by in-situ reaction, the steps are as follows:

[0035] (1) Weigh 79g alumina, 20g 3mol% Y 2 o 3 Stabilized zirconia, 1g of praseodymium nitrate, and 1.58g of polyacrylic acid were added to a planetary ball mill tank with 50mL of absolute ethanol as the medium, and ball milled at a speed of 350r / min for 8 hours to obtain a precursor slurry;

[0036] (2) Pour the above-mentioned precursor slurry into a rotary evaporator dryer, continue heating and rotating at a water bath temperature of 60°C for 1 hour, and pass through a 100-mesh sieve to obtain a precursor powder;

[0037] (3) The above-mentioned precursor powder is granulated with a polyvinyl alcohol aqueous solution with a concentration of 5% (the amount of polyvinyl alcohol is 1 wt% of the mixed powder), and then dry-pressed under a pressure of 20 MPa to obtain a ceramic green body;

[0038] (4) The above-mentioned ceramic gr...

Embodiment 3

[0040] In this embodiment, a method for preparing an alumina-based composite bioceramic material by in-situ reaction, the steps are as follows:

[0041] (1) Weigh 75g alumina, 20g 3mol% Y 2 o 3 Stabilized zirconia, 5g of praseodymium nitrate, and 2.25g of polyacrylic acid were mixed with 50mL of absolute ethanol in a planetary ball mill tank at a speed of 400r / min for 8 hours to obtain a precursor slurry;

[0042] (2) Pour the above-mentioned precursor slurry into a rotary evaporating dryer and continue to heat and spin-dry at a water bath temperature of 60°C for 2 hours, then pass through a 100-mesh sieve to obtain a precursor powder;

[0043](3) The above-mentioned precursor powder is granulated with a polyvinyl alcohol aqueous solution with a concentration of 5% (the amount of polyvinyl alcohol is 1.5 wt% of the mixed powder), and then dry-pressed under a pressure of 20 MPa to obtain a ceramic green body;

[0044] (4) The above-mentioned ceramic green body is heated up to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com