High-temperature-resistant sleeve grouting material for steel bar connection and preparation method thereof

A technology of sleeve grouting and high temperature resistance, which is applied in the field of concrete materials, can solve the problem that the connection of steel bars is not as good as cast-in-place, and achieve the effects of compensating for strength loss, high mechanical properties, and reducing the risk of disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

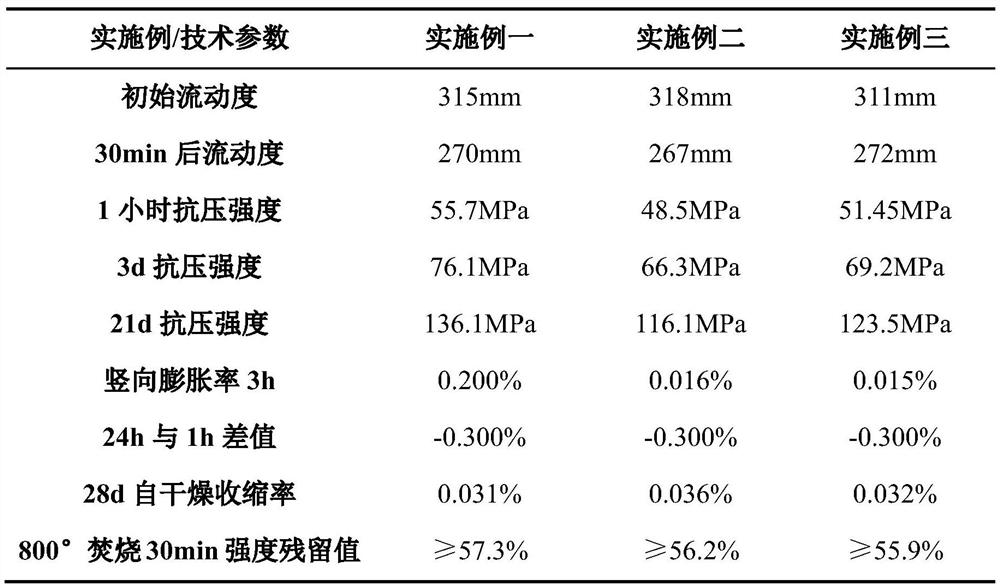

Embodiment 1

[0026] This embodiment discloses a high-temperature-resistant sleeve grouting material for steel bar connection. First, 25% of P.O52.5 Portland cement, 4% of high-alumina cement, 2.8% of S95 mineral powder, and 1.5% of silica fume in component A are disclosed. , F class I fly ash 9%, quartz sand mill fine powder 7%, plastic expansion agent 0.6%, magnesia fine aggregate with fineness modulus 2.7 16.68%, blast furnace steel slag fine aggregate after high temperature autoclaving treatment 16%, 1.8% polyoxymethylene fiber with a diameter of 0.2mm and a length of 4.0mm, 2.5% ceramic fiber, and 1.5% dihydrate gypsum were put into the mixer and mixed for 3 minutes, then added 8% water in component B, 0.02% graphene oxide, polycarboxylate 2% acid superplasticizer mother liquor, 1.5% polycarboxylic acid slump retaining mother liquor, 0.05% air-entraining agent, 0.05% defoamer and continue to stir and mix for 3 minutes to obtain sleeve grouting material. The sleeve grouting material has...

Embodiment 2

[0028] This embodiment discloses a high-temperature-resistant sleeve grouting material for steel bar connection. First, in component A, 26% of P.O52.5 Portland cement, 5% of high-alumina cement, 2.8% of S95 mineral powder, and 1.5% of silica fume , F class I fly ash 5%, quartz sand mill fine powder 8%, plastic expansion agent 0.6%, magnesia fine aggregate with fineness modulus 2.7 14.5%, blast furnace steel slag fine aggregate after high temperature autoclaving treatment 19.18%, 1.8% polyoxymethylene fiber with a diameter of 0.2mm and a length of 4.0mm, ceramic fiber 2.5%, and dihydrate gypsum 1.5% were put into a mixer and mixed for 3 minutes, then added to component B with 8% water, graphene oxide 0.02%, polycarboxylate 2% acid superplasticizer mother liquor, 1.5% polycarboxylic acid slump retaining mother liquor, 0.05% air-entraining agent, 0.05% defoamer and continue to stir and mix for 3 minutes to obtain sleeve grouting material. The sleeve grouting material has an initi...

Embodiment 3

[0030]This embodiment discloses a high-temperature-resistant sleeve grouting material for steel bar connection. First, in component A, 22% of P.O52.5 Portland cement, 3.18% of high-alumina cement, 1.8% of S95 mineral powder, and 1% of silica fume , Class F, Class I fly ash 9.5%, quartz sand mill fine powder 9%, plastic expansion agent 0.6%, magnesia fine aggregate with fineness modulus 2.7 17.5%, blast furnace steel slag fine aggregate after high-temperature autoclaved treatment 16%, 1.8% polyoxymethylene fiber with a diameter of 0.2mm and a length of 4.0mm, 2.5% ceramic fiber, and 1.5% dihydrate gypsum were put into the mixer and mixed for 3 minutes, then added 10% water in component B, 0.01% graphene oxide, polycarboxylate 2% acid superplasticizer mother liquor, 1.5% polycarboxylic acid slump retaining mother liquor, 0.05% air-entraining agent, 0.06% defoamer and continue to stir and mix for 3 minutes to obtain sleeve grouting material. The sleeve grouting material has an in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com