Anti-penetration and anti-explosion cement-based protective engineering material and preparation method thereof

An engineering material, cement-based technology, applied in the field of protection engineering, can solve the problem of not considering the composite effect of penetration and explosion, and achieve the effect of being conducive to ecological sustainable development, wide range of sources, and improved economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Select weight percent cement 20.6%, industrial waste residue 20.6% (silica fume: slag=2:3), nano-SiO 20.41%, yellow sand 49.5% put into the blender and mix evenly; add the mixed solution of 0.62% polycarboxylate water reducer, 0.0012% 753W type defoamer and 8.25% water into the blender, so that the solid raw materials from the dispersed state It becomes a viscous slurry state, and an ultra-high performance mortar is obtained.

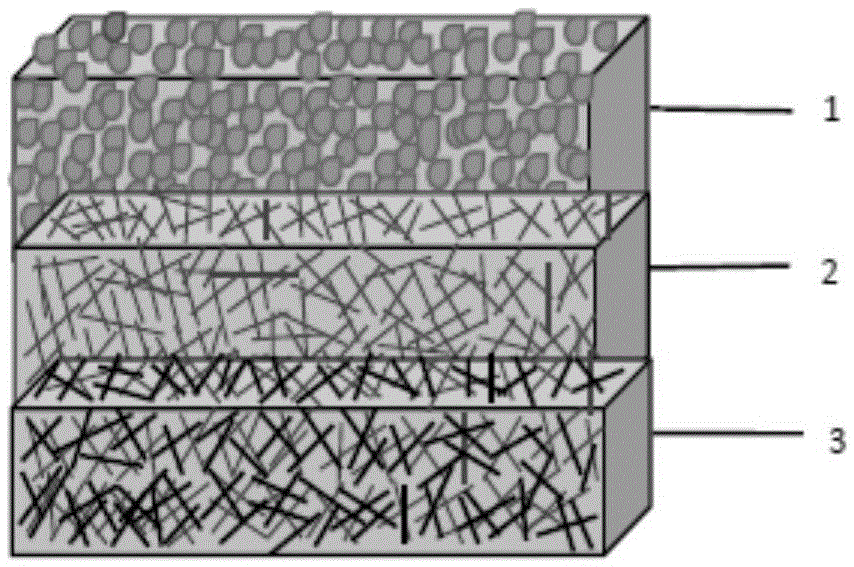

[0047] Add the hybrid fiber of 3% steel fiber and 1% polyvinyl alcohol fiber into the mixer, and pour the prepared hybrid fiber reinforced ultra-high performance cement-based composite material into the mold, which has self-compacting property and does not need vibration.

[0048] Repeat the above steps for preparing ultra-high-performance mortar, add 3% steel fiber by volume into the mixer, and pour the prepared steel fiber-reinforced ultra-high-performance cement-based composite material into the mold as the middle layer.

[0049] Repeat the a...

Embodiment 2

[0053] Choose weight percent cement 18.8%, industrial waste residue 22.6% (silica fume: tailings powder=2:3), nanometer Al 2 o 3 0.83%, yellow sand 49.6% put into the blender and mix evenly; add the mixed solution of 0.74% polycarboxylate water reducer, 0.0017% 753W type defoamer and 7.45% water into the blender, so that the solid raw materials from the dispersed state It becomes a viscous slurry state, and an ultra-high performance mortar is obtained.

[0054] Add the hybrid fiber of 2% steel fiber and 1% polyvinyl alcohol fiber into the mixer, and pour the prepared hybrid fiber reinforced ultra-high-performance cement-based composite material into the mold, which has self-compacting properties and does not need vibration.

[0055] Repeat the above steps for preparing ultra-high-performance mortar, add 4% steel fiber by volume into the mixer, and pour the prepared steel fiber-reinforced ultra-high-performance cement-based composite material into the mold as the middle layer....

Embodiment 3

[0060] Select weight percent cement 18.8%, industrial waste residue 26.3% (silica fume: slag: tailings powder=2:2:1), nano-SiO 2 0.9%, yellow sand 45.1% put into the blender and mix evenly; add the mixed solution of 0.81% polycarboxylate superplasticizer, 0.0023% 753W type defoamer and 8.12% water into the blender, so that the solid raw materials change from dispersed state to into a viscous slurry state to obtain ultra-high performance mortar.

[0061] Add hybrid fibers of 2% steel fiber and 1% basalt fiber into the mixer, and pour the prepared hybrid fiber reinforced ultra-high performance cement-based composite material into the mold, which has self-compacting properties and does not require vibration.

[0062] Repeat the above steps for preparing ultra-high-performance mortar, add 4% steel fiber by volume into the mixer, and pour the prepared steel fiber-reinforced ultra-high-performance cement-based composite material into the mold as the middle layer.

[0063] Repeat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com