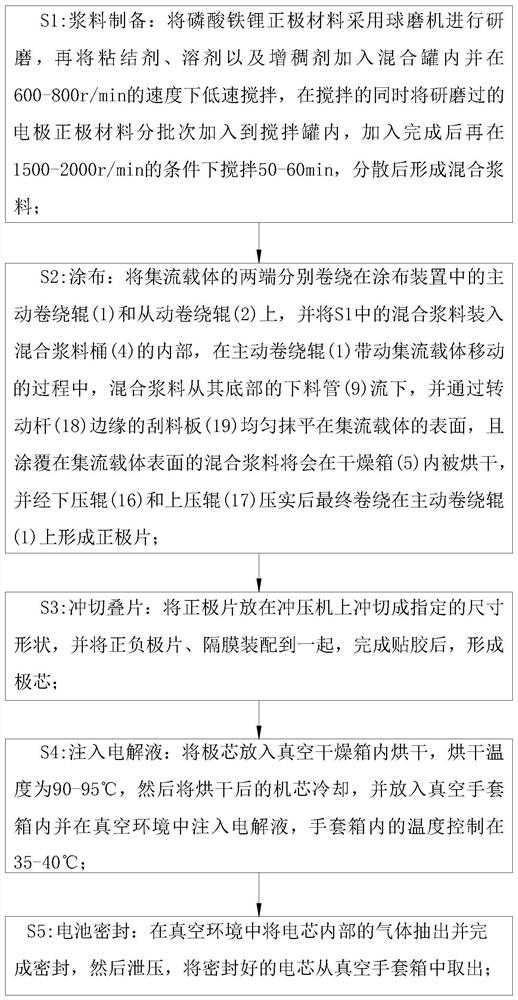

Lithium battery production process

A production process and lithium battery technology, applied in the direction of secondary batteries, battery electrodes, electrochemical generators, etc., can solve the problems of inconvenient adjustment or adjustment, the thickness of the coating machine, and the reduction of lithium battery charge and discharge performance, etc., to achieve Effects of improving life, eliminating air bubbles, and improving discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

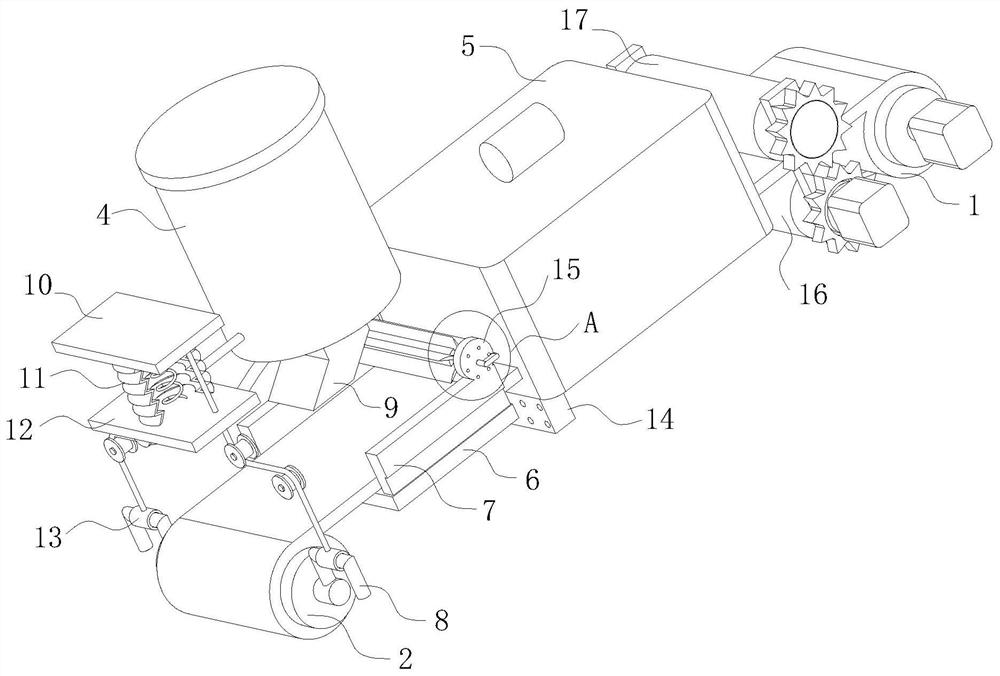

Method used

Image

Examples

Embodiment approach

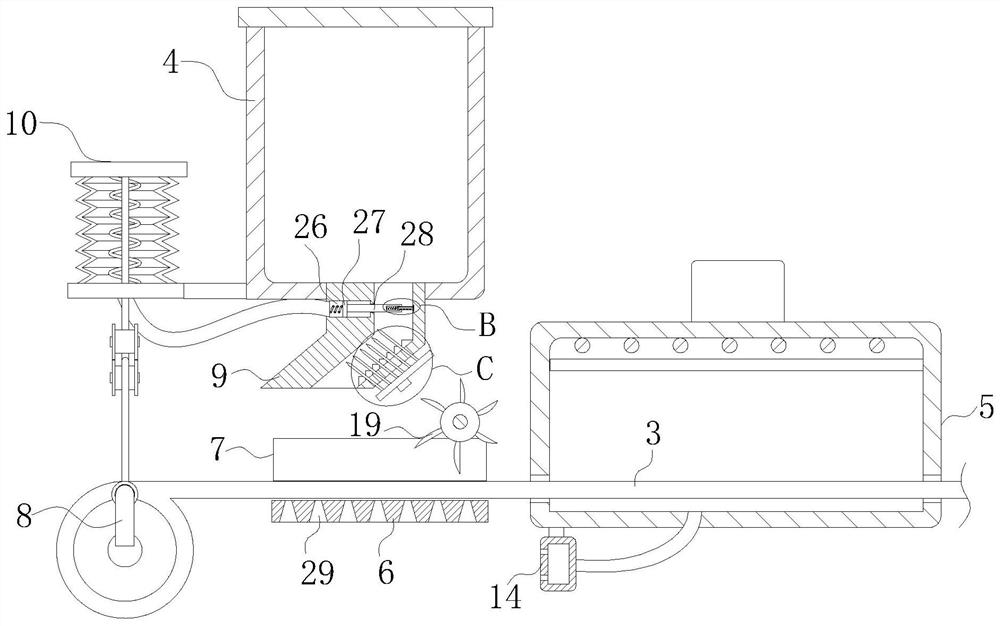

[0043] As an embodiment of the present invention, rubber rollers 24 are evenly arranged on the edge of the rotating rod 18 inside the annular chute 25; the rotating shafts at both ends of the rubber roller 24 are fixedly connected to the edges of the rotating rod 18 through springs; At this time, the rubber roller 24 is elastically pressed against the inner wall of the annular chute 25, thereby making the rotation of the rotating rod 18 more stable, making the adjustment of the position more accurate, and preventing the gap between the rotating rod 18 and the annular chute 25 from being too large. , and then when the rotating rod 18 is adjusted to a suitable position, the rotating rod 18 will still have a slight position shift, and the rubber roller 24 itself can rotate around its own rotating shaft, so that the rotation of the rotating rod 18 will not consume a lot of effort.

[0044] As an embodiment of the present invention, several groups of columnar sliding grooves 30 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com