High-speed railway bridge assembly type damping device and application method and replacement method thereof

A high-speed railway and damping device technology, applied in the field of bridge damping, can solve problems such as difficulty in dismantling and replacement, difficulty in monitoring deformation, unfavorable seismic performance of bridge structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

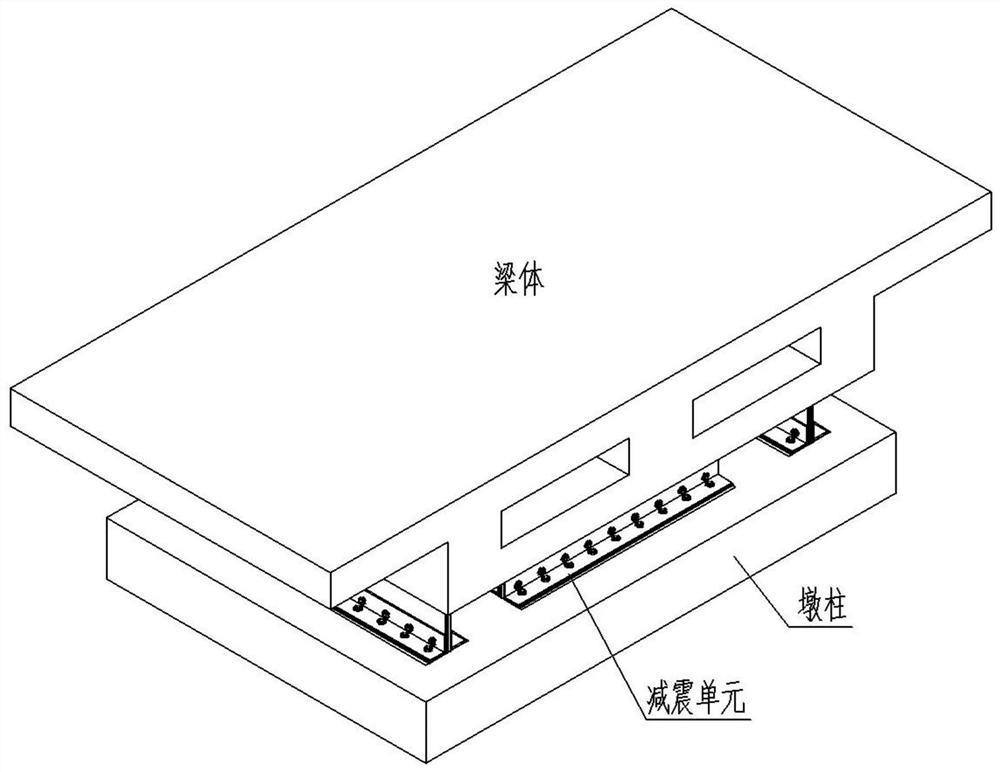

[0036] combine figure 1 , figure 2 It can be seen that the high-speed railway bridge assembly-type steel plate shear wall damping device disclosed in this embodiment includes multiple sets of damping units arranged around the support at the center of the top of the pier column.

[0037] combine Figure 1 to Figure 3 It can be seen that each group of damping units includes two sets of T-shaped main body 1 and its connected horizontal energy-dissipating plate 2, angle steel 3, anchor member 4 and fastener assembly components. Relatively arranged, the vertical energy dissipation plate 5, angle steel 3 and fasteners are connected to form an integral part with an I-shaped cross-section of the assembled main structure.

[0038] combine image 3 with Figure 4 It can be seen that the top surface of the wing plate of the T-shaped main body 1 is symmetrically connected with two rows of anchor members 4 with respect to its longitudinal center plane, and the horizontal energy dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com