LaCl3 cross-linked high-strength high-modulus polyvinyl alcohol fiber and preparation method thereof

A polyvinyl alcohol fiber, high-strength and high-modulus technology, applied in the directions of fiber chemical characteristics, spinning solution preparation, wet spinning, etc., to achieve the effects of increased stretching ratio, active chemical properties, and improved breaking strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A LaCI 3 The preparation method of the high-strength high-modulus polyvinyl alcohol fiber of crosslinking, its step is as follows:

[0037] (1) Dissolve polyvinyl alcohol with a degree of alcoholysis of 98% and a degree of polymerization of 1700 in DMSO, and add LaCl 3 , until the polyvinyl alcohol is completely dissolved to obtain the spinning solution; in the spinning solution, the mass fraction of polyvinyl alcohol is 13.2wt%, LaCl 3 The mass fraction of is 0.50wt%;

[0038] (2) The spinning solution is degassed for 3 hours at a temperature of 78°C;

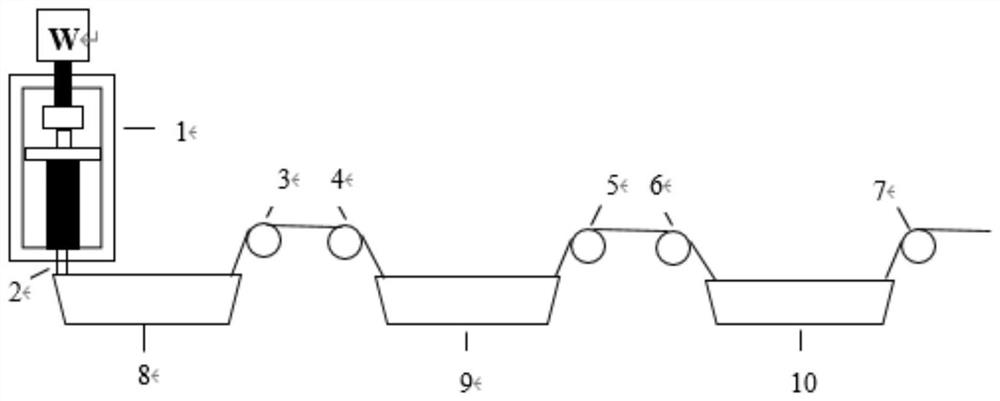

[0039] (3) The spinning liquid is subjected to wet spinning; wherein, the wet spinning process is as follows: the extrusion rate of the spinneret hole is 4.0ml / min, the spinning temperature is 88°C, and the diameter of the spinneret hole is 0.31mm;

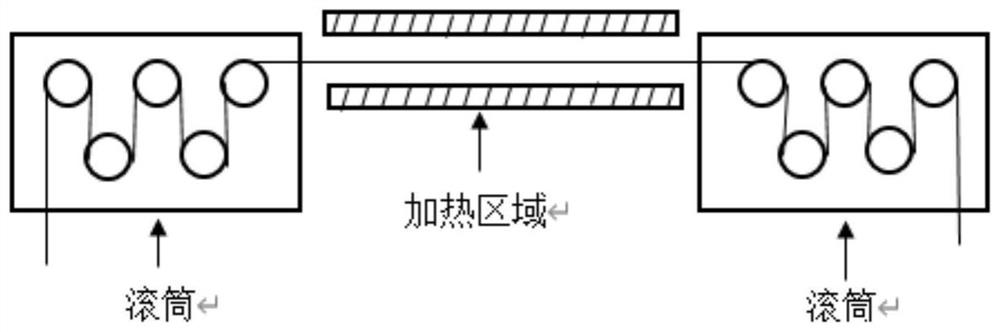

[0040] (4) The as-spun fiber obtained by spinning passes through the first-stage coagulation bath (solidification time is 1.8min) with ethanol as the solvent at a temper...

Embodiment 2

[0050] a LaCl 3 The preparation method of the high-strength high-modulus polyvinyl alcohol fiber of crosslinking, its step is as follows:

[0051] (1) Dissolve polyvinyl alcohol with a degree of alcoholysis of 99% and a degree of polymerization of 1900 in DMSO, and add LaCl 3 , to obtain the spinning solution after polyvinyl alcohol is completely dissolved; in the spinning solution, the mass fraction of polyvinyl alcohol is 13.8wt%, LaCl 3 The mass fraction of is 0.56wt%;

[0052] (2) The spinning solution is degassed for 2.9 hours at a temperature of 80°C;

[0053] (3) The spinning liquid is subjected to wet spinning; wherein, the wet spinning process is: the extrusion rate of the spinneret hole is 3.9ml / min, the spinning temperature is 85°C, and the diameter of the spinneret hole is 0.30mm;

[0054] (4) The as-spun fiber obtained by spinning passes through the first-stage coagulation bath with methanol as the solvent at a temperature of -10°C (the curing time is 1.9min), ...

Embodiment 3

[0057] a LaCl 3 The preparation method of the high-strength high-modulus polyvinyl alcohol fiber of crosslinking, its step is as follows:

[0058] (1) Dissolve polyvinyl alcohol with a degree of alcoholysis of 99% and a degree of polymerization of 2600 in DMSO, and add LaCl 3 , until the polyvinyl alcohol is completely dissolved to obtain the spinning solution; in the spinning solution, the mass fraction of polyvinyl alcohol is 14wt%, LaCl 3 The mass fraction of is 0.72wt%;

[0059] (2) Degassing treatment of the spinning solution for 3.0 hours at a temperature of 79°C;

[0060] (3) The spinning liquid is subjected to wet spinning; wherein, the wet spinning process is: the extrusion rate of the spinneret hole is 3.8ml / min, the spinning temperature is 90°C, and the diameter of the spinneret hole is 0.32mm;

[0061] (4) The as-spun fiber obtained by spinning passes through the first-stage coagulation bath (curing time: 1.8 min) with ethanol as the solvent at a temperature of -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com