Thin packaging film with high tensile property and preparation method thereof

A technology for stretchability and packaging film, which is applied in the field of high-stretchability thin packaging film and its preparation. It can solve the problems of increased difference in stretchability, decrease in stretching ratio, and breakage of packaging film, achieving excellent performance, Guaranteed stretching effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

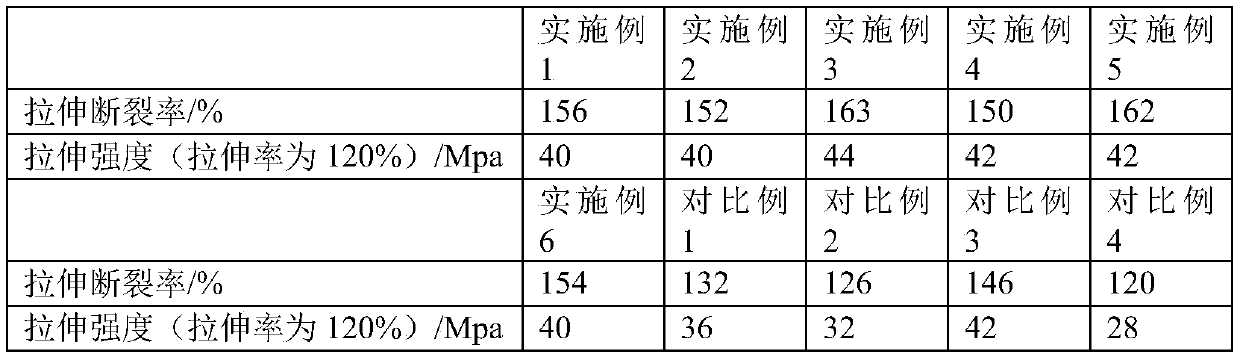

Examples

Embodiment Embodiment 1

[0077] A thin packaging film with high tensile properties is a seven-layer composite film. The thickness of the seven-layer composite film is 10-12 μm. The seven-layer composite film includes the first layer, the second layer, the The third, fourth, fifth, sixth and seventh floors;

[0078] The raw materials of the first layer and the seventh layer include the following components by mass:

[0079] 60-70 parts of metallocene linear low-density polyethylene;

[0080] 3-5 parts of PP elastomer;

[0081] 10-15 parts of low-density polyethylene;

[0082] 0.8-1.2 parts of oleic acid amide;

[0083] The raw materials of the second layer and the sixth layer include the following components by mass:

[0084] 65-75 parts of metallocene linear low-density polyethylene;

[0085] 8-12 parts of PP elastomer;

[0086] 10-15 parts of low-density polyethylene;

[0087] 1.5-3 parts of tannin phenolic compounds;

[0088] 4-8 parts of maleic anhydride;

[0089] 2-4 parts of chitosan, th...

Embodiment 7

[0130] A thin packaging film with high tensile properties, based on Example 3, the difference is that the raw material components of the second layer / sixth layer are swapped with the raw material components of the first layer / seventh layer.

[0131] The surface of the obtained packaging film of Example 7 has waviness and deformation, and the thickness is different. The tensile fracture rate is 140%, and the tensile strength (the tensile rate is 120%) is 38 MPa.

[0132] Comparing Example 7 and Example 3, it can be seen that the second layer and the sixth layer are mixed with tannin phenolic compound and maleic anhydride in the present application, and the first layer and the seventh layer protect the second layer and the sixth layer , to reduce the deformation of the second layer and the sixth layer caused by the temperature difference during the cooling process after extrusion, and prevent the deformation of the packaging film.

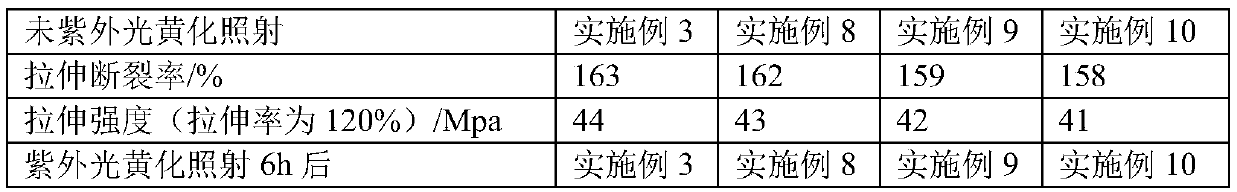

Embodiment 8

[0134] A thin packaging film with high tensile properties, based on Example 3, the difference is that the amount of nano-scale tin oxide in the second layer / sixth layer is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com