Method for removing bubbles in No.45 steel

A technology of No. 45 steel and air bubbles, which is used in the improvement of process efficiency and the manufacture of converters, etc., can solve the problem of reusable cycle times to be considered, does not mention the removal of steel-slag interface pass performance, and does not provide refining slag In order to improve the bubble passing performance, avoid pore defects, and optimize the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

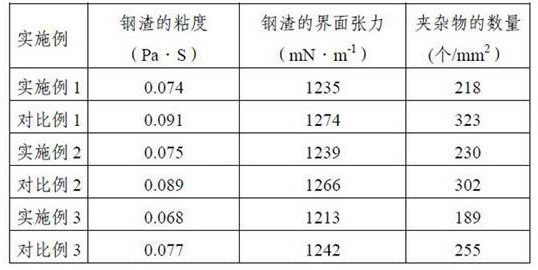

[0079] In the present embodiment, the chemical composition of the steel slag formed is: CaO: 50%, Al 2 o 3 : 29%, MgO: 6%, SiO 2 : 9%, CaF 2 : 5%, of which CaO / Al 2 o 3 ≈1.72, Al 2 o 3 / SiO 2 ≈3.2, alkalinity (CaO / SiO 2 )≈5.6, and the rest are unavoidable impurities contained in raw materials.

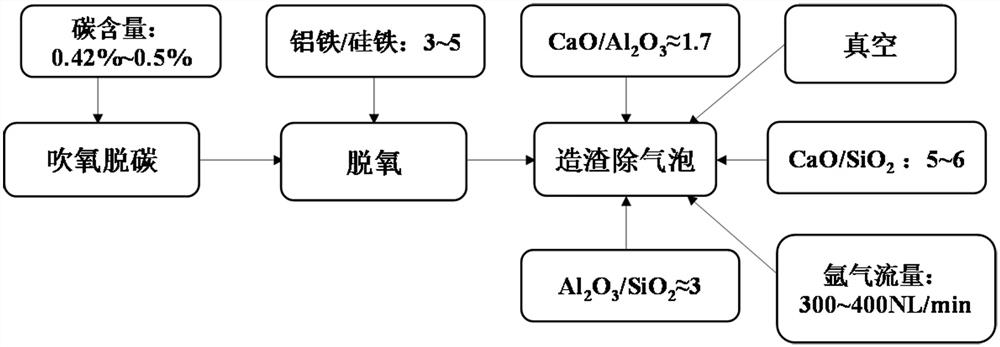

[0080] In this embodiment, the specific operation process is:

[0081] Oxygen blowing: In the process of converter steelmaking, the top-bottom combined blowing process is adopted to supply oxygen to the metal molten pool to remove excess impurities such as carbon, silicon, phosphorus, etc. in the carbon-saturated molten iron. Oxidation state, to obtain peroxidized molten steel.

[0082] Deoxidation: In this embodiment, a composite deoxidation method combining direct deoxidation and vacuum deoxidation is adopted. Specifically, the peroxidized molten steel is tapped from the converter into the ladle furnace and added to the peroxidized molten steel with a mass ratio of aluminu...

Embodiment 2

[0093] In this implementation, the chemical composition of the steel slag formed is: CaO: 50%, Al 2 o 3 : 28%, MgO: 6%, SiO 2 : 10%, CaF 2 : 5%, of which CaO / Al 2 o 3 ≈1.78, Al 2 o 3 / SiO 2 =2.8, alkalinity (CaO / SiO 2 )=5, and the remaining substances are unavoidable impurities contained in raw materials.

[0094] In this embodiment, the specific operation process is:

[0095] Oxygen blowing: In the process of converter steelmaking, the top-bottom combined blowing process is adopted to supply oxygen to the metal molten pool to remove excess impurities such as carbon, silicon, phosphorus, etc. in the carbon-saturated molten iron. Oxidation state, to obtain peroxidized molten steel.

[0096] Deoxidation: In this embodiment, a composite deoxidation method combining direct deoxidation and vacuum deoxidation is adopted. Specifically, the peroxidized molten steel is tapped from the converter into the ladle furnace and added to the peroxidized molten steel with a mass rati...

Embodiment 3

[0107] In the present embodiment, the chemical composition of the steel slag formed is: CaO: 50%, Al 2 o 3 : 29%, MgO: 5%, SiO 2 : 10%, CaF 2 : 5%, of which CaO / Al 2 o 3 ≈1.72, Al 2 o 3 / SiO 2 =2.9, alkalinity (CaO / SiO 2 )=5, and the remaining substances are unavoidable impurities contained in raw materials.

[0108] The specific operation process is:

[0109] Oxygen blowing: In the process of converter steelmaking, the top-bottom combined blowing process is adopted to supply oxygen to the metal molten pool to remove excess impurities such as carbon, silicon, phosphorus, etc. in the carbon-saturated molten iron. Oxidation state, to obtain peroxidized molten steel.

[0110] Deoxidation: In this embodiment, a composite deoxidation method combining direct deoxidation and vacuum deoxidation is adopted. Specifically, the peroxidized molten steel is tapped from the converter into the ladle furnace and added to the peroxidized molten steel with a mass ratio of aluminum-iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com