Automatic rapid batch code scanning assembly line for small express items and processing method thereof

An assembly line and express mail technology, which is applied in image data processing, conveyor objects, computer parts, etc., can solve the problems of large overall structure, long assembly line, and increased detection equipment settings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

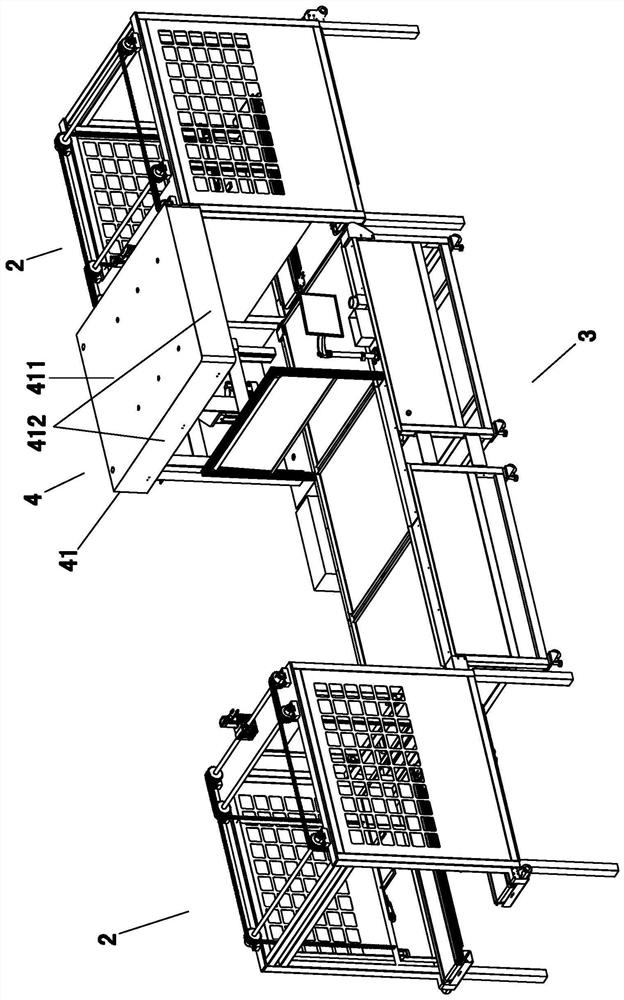

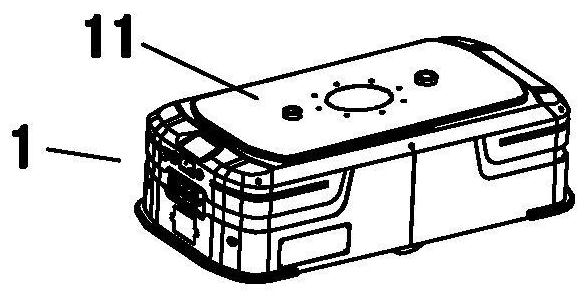

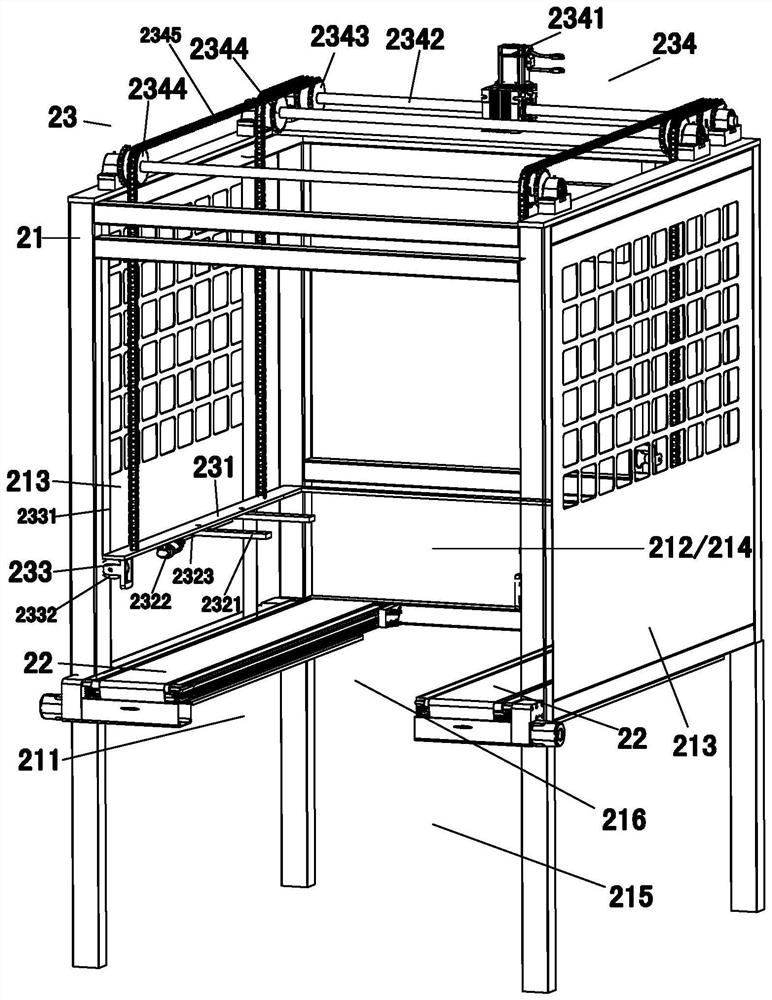

[0081] The invention discloses a small-scale express automatic fast batch code scanning assembly line, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it mainly includes the following parts, including an automatic transport vehicle 1, a pallet feeder 2, a conveyor line 3, a batch code scanning machine 4 and a control system (not shown in the figure), and the pallet feeder 2 is on the conveyor line The two ends of the input and output of 3 are respectively set, that is, the input and output of the conveying line 3 are all conveyed by the tray feeder 2, and the batch scanning machine 4 includes a camera installed above the output end of the conveying line 3 The frame 41 and the supporting connection device 42 arranged on the side of the conveyor line 3 to support and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com