Preparation method and application of calcium hydroxide-loaded graphene aerogel composite material

A graphene aerogel, calcium hydroxide technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, separation methods, etc., can solve problems such as limited absorption, complex production process, etc., and achieve synthesis costs. Low, excellent air permeability, the effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

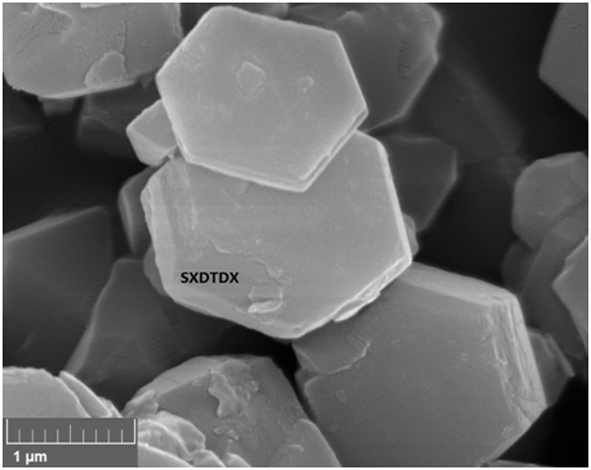

[0037] Graphite paper is used as electrolytic anode, graphite or nickel-based corrosion-resistant alloy is used as cathode, 98% concentrated sulfuric acid is used as electrolyte, graphite paper is immersed in concentrated sulfuric acid, and a voltage of +1.5V is applied for electrolytic intercalation reaction to obtain thickness increase 8x intercalated graphite paper. Using intercalated graphite paper as the anode, using dilute sulfuric acid or dilute nitric acid as the electrolyte, applying a voltage of +9V, slowly immersing the intercalated graphite paper in the electrolyte for electrolytic oxidation reaction, to obtain pure graphene oxide free of heavy metal ions. For the preparation of calcium hydroxide, weigh 10.8 g of sodium hydroxide and dissolve it in 2 L of deionized water, and weigh 17.98 g of anhydrous calcium chloride and dissolve it in 100 mL of ionized water. Stir the sodium hydroxide solution at room temperature at high speed, then add the calcium chloride solu...

Embodiment 2

[0039] Graphite paper is used as electrolytic anode, graphite or nickel-based corrosion-resistant alloy is used as cathode, 98% concentrated sulfuric acid is used as electrolyte, graphite paper is immersed in concentrated sulfuric acid, and a voltage of +1.5 V is applied for electrolytic intercalation reaction. Graphite or nickel The base corrosion-resistant alloy was used as the cathode, and the intercalated graphite paper whose thickness was increased by 8 times was obtained. Use intercalated graphite paper as the anode, use dilute sulfuric acid or dilute nitric acid as the electrolyte, apply a voltage of +9 V, slowly immerse the intercalated graphite paper in the electrolyte for electrolytic oxidation reaction, and wash it with deionized water for many times to obtain oxidation Graphene. For the preparation of calcium hydroxide, weigh 10.8 g of sodium hydroxide and dissolve it in 2 L of deionized water, and weigh 17.98 g of anhydrous calcium chloride and dissolve it in 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com