Copper nut and preparation method thereof

A copper nut, quality percentage technology, applied in the direction of nuts, mechanical equipment, threaded fasteners, etc., can solve problems such as the service life can only be maintained at about 1 year, unreasonable phase composition control, poor comprehensive performance of copper nuts, etc. , to achieve the effect of improving the uniformity of mechanical properties, refining grains and increasing strength

Active Publication Date: 2022-01-07

SHANXI BUYEASY MACHINERY MFG

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

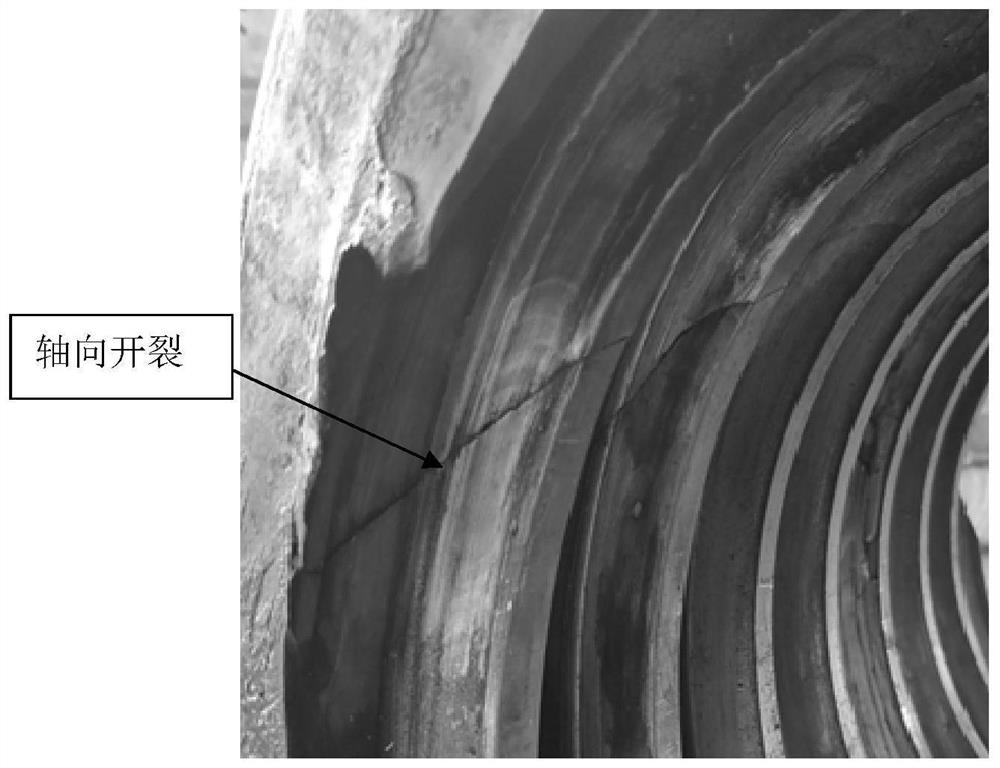

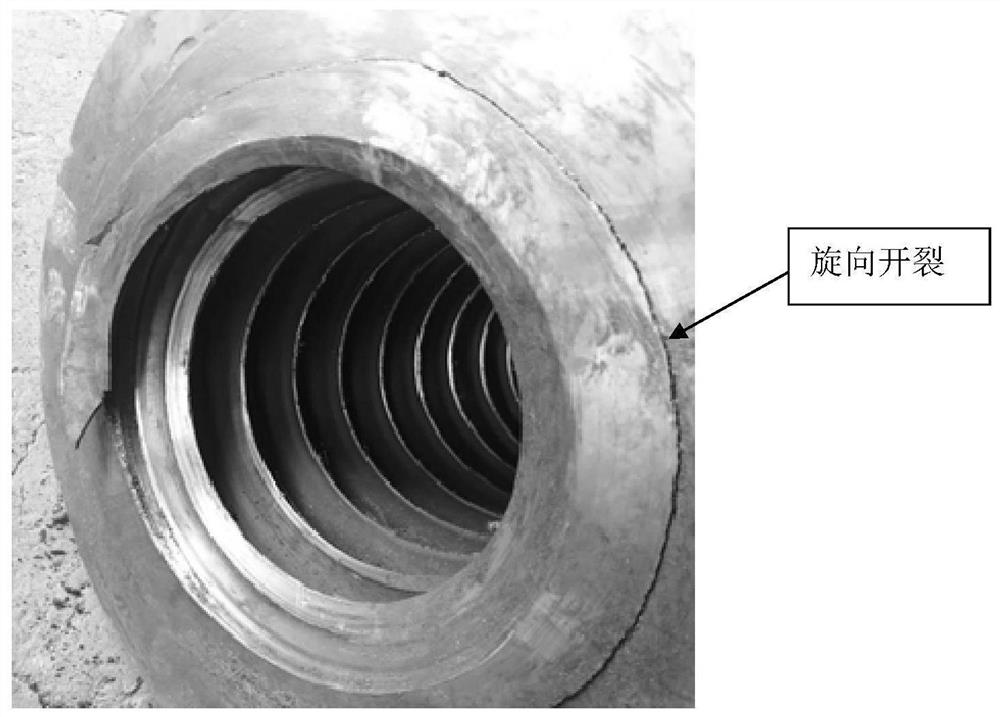

[0005] The current grade of copper alloy for producing copper nuts is generally the national standard ZCuZn26Al4Fe3Mn3. The tensile strength of the material is generally about 600MPa, the yield strength is about 300MPa, the hardness is about 130HB, and the elongation is about 13%. On the one hand, due to the low strength and hardness, As a result, the existing copper alloy has poor wear resistance, and its service life can only be maintained at about 1 year. On the other hand, because the copper nut is a cast product, there is no subsequent extrusion processing, etc. Therefore, in the case of improper process control Under the circumstances, there will be pores in the matrix, unreasonable phase composition control, etc., resulting in uneven mechanical properties, poor comprehensive performance of copper nuts, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

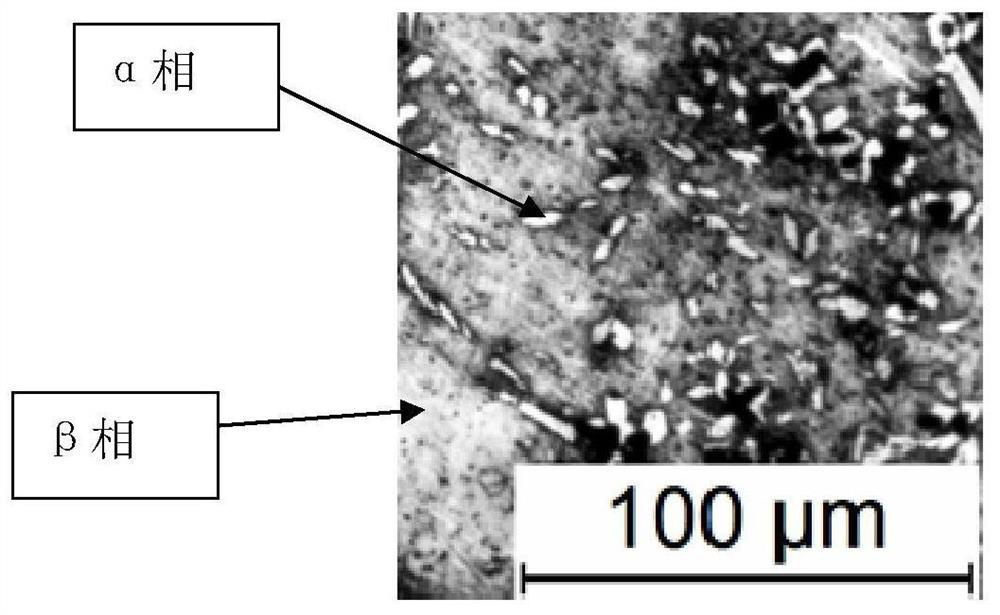

The invention relates to a copper nut, which is characterized in that it consists of the following mass percentages: Cu: 56-63wt%, Al: 2.5-6.5wt%, Fe: 1.5-4.5wt%, Mn: 1.5-4.5wt%, and The amount is Zn and unavoidable impurities; the microstructure of copper nuts contains matrix phase β phase, α phase and Fe-rich K phase. The present invention controls the addition amount of copper, and adds Al, Fe, Mn to brass and controls its content, makes the microstructure of copper nut contain matrix phase β phase, α phase and K phase rich in Fe, in improving strength , hardness while ensuring the elongation, and the K phase rich in Fe is dispersed in the alloy, which refines the grains and improves the uniformity of the mechanical properties of the alloy.

Description

technical field [0001] The invention belongs to the field of copper alloys, and in particular relates to a copper nut and a preparation method thereof. Background technique [0002] Friction and screw presses are currently the mainstream forging equipment in China. They have the characteristics of simple structure, easy installation, simple operation and auxiliary equipment, and low price. Pressure processing of materials. The copper nut is an important component of the press, which is directly related to the production capacity of the press. [0003] The copper nut cooperates with the screw to reciprocate up and down in the fuselage to generate transmission friction. At the same time, the press exerts an impact force on the workpiece during the working process, and the teeth of the copper nut bear extrusion stress, shear stress, and bending stress. The normal service life of the copper nut is about 1 year. During this period, the copper nut has no cracks or broken teeth. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C9/04F16B37/00

CPCC22C9/04F16B37/00

Inventor 何勋焦小亮何清杨旭东王钰

Owner SHANXI BUYEASY MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com