Additive for silicon wafer cleaning and application thereof

A silicon wafer cleaning and additive technology, which is applied in the direction of detergent compounding agent, detergent composition, cleaning method and utensils, can solve the problems of increasing the cost of pre-cleaning operation, increasing the cost of wastewater treatment, and large content, so as to achieve the improvement of battery The effect of improving chip yield, improving appearance cleanliness, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

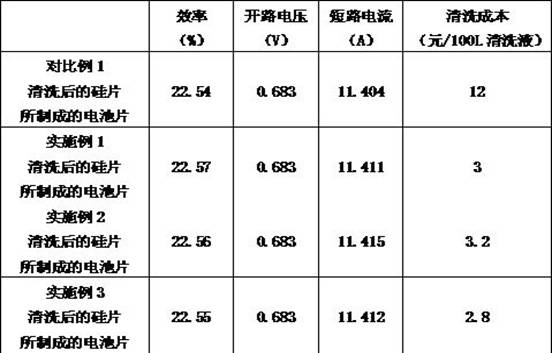

Examples

Embodiment 1

[0036] Perform pre-cleaning operations on silicon wafers with fingerprints in the early stage of the texturing process. The specific steps include:

[0037] 1) Preparation of additives: 3.5% sodium benzoate, 1.2% chitosan, 0.5% fatty alcohol polyoxyethylene ether, 1.8% glycerol, and 2.2% polyvinyl alcohol were added to the remaining amount of water, mix evenly to make additives;

[0038] 2) Preparation of cleaning solution: add the additive prepared in step 1) to the alkaline solution, mix well to make a cleaning solution; the mass ratio of additive to alkaline solution is 0.5:100; the alkaline solution is an aqueous solution of sodium hydroxide, and the alkali Hydrogen peroxide is added into the solution; the alkaline solution contains 0.06wt% sodium hydroxide and 0.9wt% hydrogen peroxide;

[0039] 3) Put the silicon wafer into the cleaning solution prepared in step 2), and clean it at 60°C for 120s.

Embodiment 2

[0041] Perform pre-cleaning operations on silicon wafers with fingerprints in the early stage of the texturing process. The specific steps include:

[0042] 1) Preparation of additives: adding 5% sodium benzoate, 2% chitosan, 1% fatty alcohol polyoxyethylene ether, 3% glycerol, and 1% polyvinyl alcohol to the remaining amount of water, mix evenly to make additives;

[0043] 2) Preparation of cleaning solution: add the additive prepared in step 1) to the alkaline solution, mix well to make a cleaning solution; the mass ratio of the additive to the alkaline solution is 2:100; the alkaline solution is an aqueous solution of sodium hydroxide, and the alkaline Hydrogen peroxide is added into the solution; the alkaline solution contains 0.1wt% sodium hydroxide and 1.5wt% hydrogen peroxide;

[0044] 3) Put the silicon wafer into the cleaning solution prepared in step 2), and clean it at 68°C for 100s.

Embodiment 3

[0046] Perform pre-cleaning operations on silicon wafers with fingerprints in the early stage of the texturing process. The specific steps include:

[0047] 1) Preparation of additives: Add 2% sodium benzoate, 1% chitosan, 0.5% fatty alcohol polyoxyethylene ether, 1% glycerol, and 3% polyvinyl alcohol to the remaining amount of water, mix evenly to make additives;

[0048] 2) Preparation of cleaning solution: add the additive made in step 1) to the alkaline solution, mix well to make a cleaning solution; the mass ratio of additive to alkaline solution is 0.1:100; the alkaline solution is an aqueous solution of sodium hydroxide, and the alkali Hydrogen peroxide is added into the solution; the alkali solution contains 0.08wt% sodium hydroxide and 1wt% hydrogen peroxide;

[0049] 3) Put the silicon wafer into the cleaning solution prepared in step 2), and clean it at 68°C for 120s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com