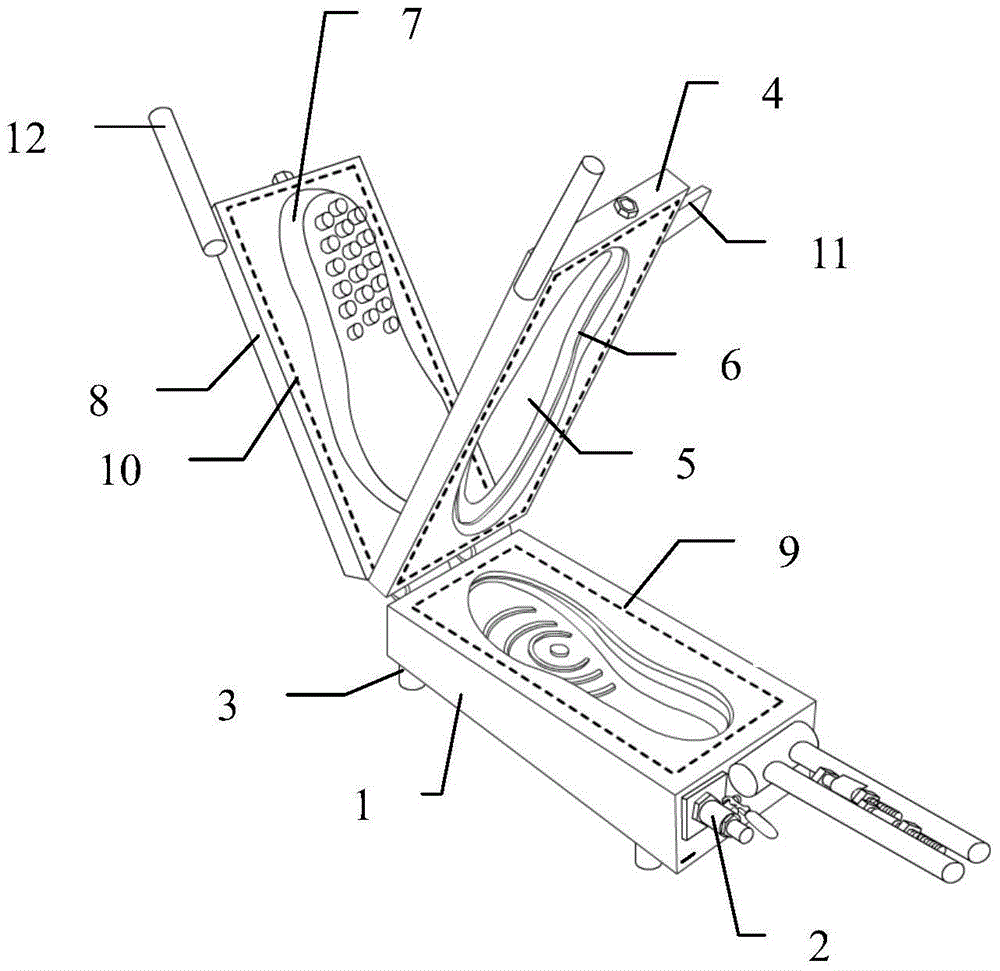

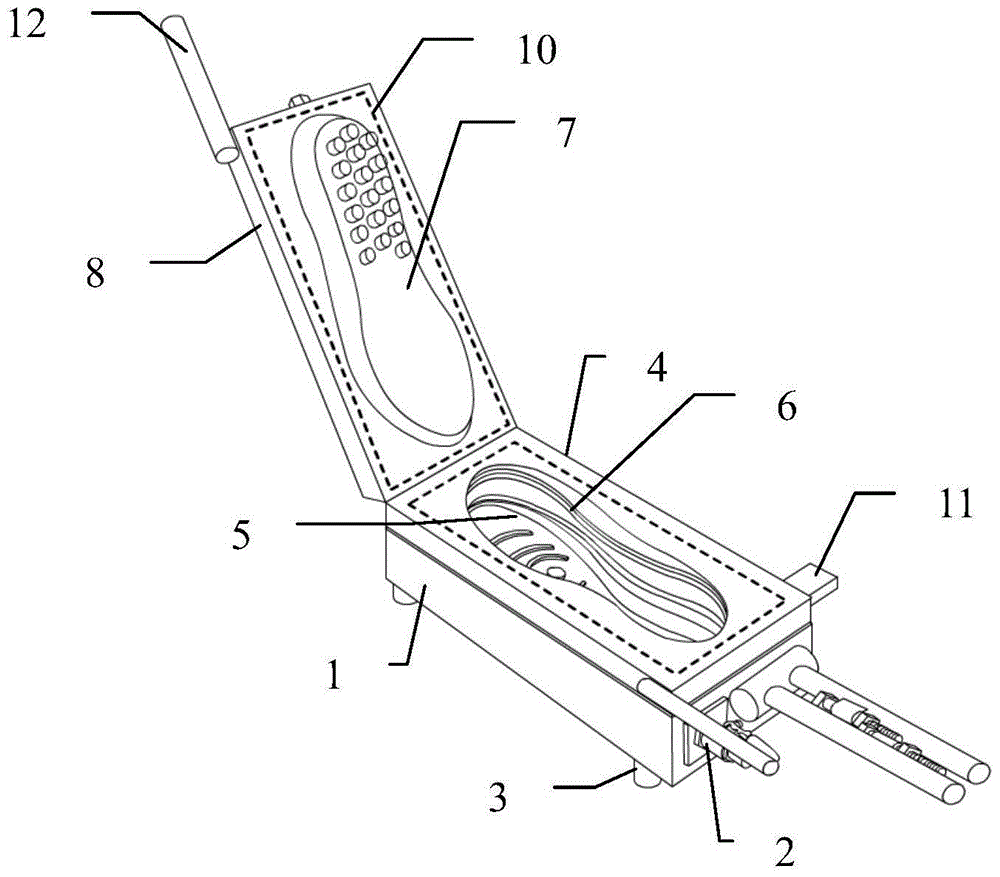

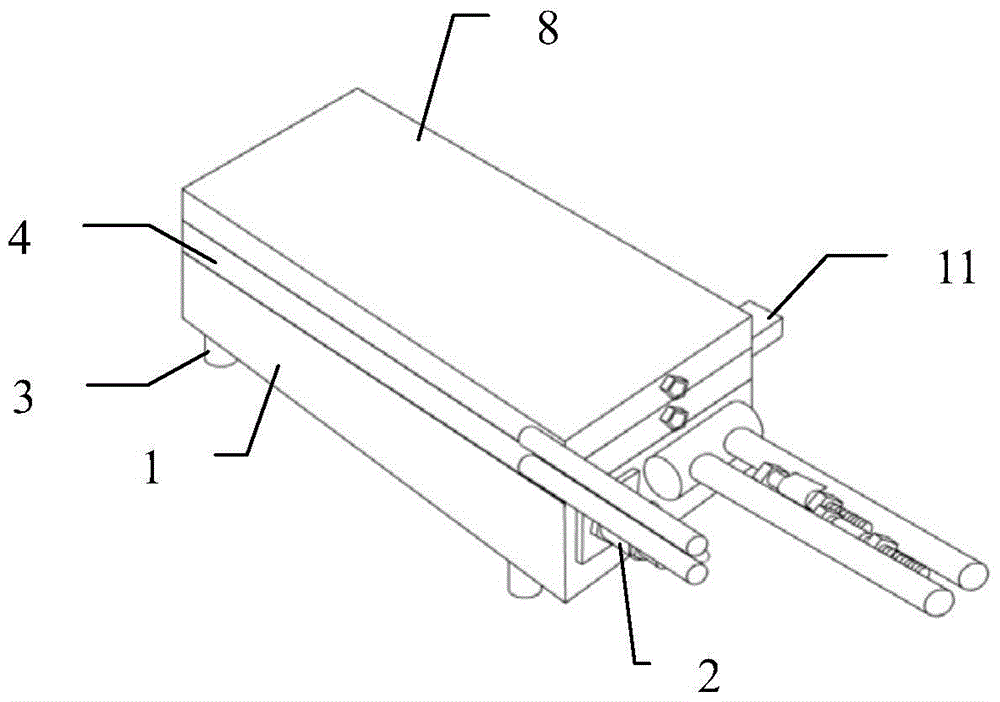

A shoe sole forming mold and a method for shoe sole suction molding using the same

A technology for forming molds and bottom molds, which is applied in the field of shoe sole suction molding and shoe sole forming molds. It can solve problems such as shrinkage, hydrolysis, and difficult handling, and achieve the effects of improving appearance and cleanliness, increasing airtightness, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Polyurethane TPU is used to make shoe soles. It has the advantages of light weight, high strength, good toughness, excellent wear resistance and folding resistance, wide adjustable range of hardness and density, good temperature resistance, anti-skid and oil resistance, and comfortable wearing. It is a kind of A new type of environmentally friendly product, but there will be many problems in the molding process, such as the precise requirements for the mold, there will be shallow foaming, peeling, pores, air bubbles, hydrolysis, shrinkage, etc., resulting in a high defect rate and difficult to deal with in the future. , the mold described in the present invention and the suction molding method using it mainly solve the above-mentioned problems.

[0058] Heat the complete mold to 45-60 degrees, spray the mold with release agent, then put the negative film into the bottom of the mold, then put the TPU film on the bottom mold 1, put down the middle frame 4, and fix it tight...

Embodiment 2

[0061] Heat the mold to 40-50 degrees, spray the release agent, and then put the TPU film with a thickness of 0.01-0.03 on the bottom mold 1 and put down the middle frame 4, fix it, suck the vacuum, let the TPU film directly suck into the mold cavity, and then Polyurethane is poured into the mold cavity, and the mold cover 8 is covered, and the fixing is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com