Bio-based pentamethylene diisocyanate curing agent and preparation method and application thereof

A pentamethylene diisocyanate, bio-based technology, used in organic chemistry, chemical recycling, polyurea/polyurethane coatings, etc., can solve problems such as affecting product appearance and performance, unsatisfactory catalyst dispersion, and troublesome separation. Good chemical resistance, stable and controllable reaction process, and reduced preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Examples of the present invention provide a preparation method for biological types of penta methylxylxyl axyl axyl axyls, including the following steps:

[0038] Step 1): Under the protection of nitrogen, add pupar methalisocyanate PDI to the reaction bottle;

[0039] Step 2): Add catalyst A to the reaction bottle, pre -react 0-5h at 50-150 ° C;

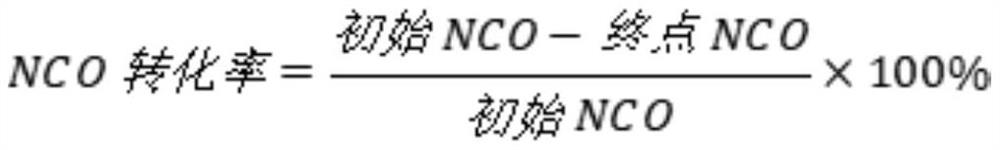

[0040] Step 3): Add PDI trimore catalyst to the reaction bottle, stir at a warming reaction of 1h to 10h at 50 ° C ° C, and test the NCO content every 15 minutes;

[0041] Step 4): When the NCO content reaches the preset content value, add a polymer to the reaction bottle. At 50 ~ 100 ℃, the insulation reaction is 1h to 5h;

[0042] Step 5): Add antioxidants D to the reaction bottle, the insulation reaction is 0.5h to 1h at 50 ~ 100 ℃, and the pdi isocyanate composition E is obtained from the discharge

[0043] Step 6): Use a film evaporator to pre -separate the product PDI isocyanate composition E to remove the PDI monomer of PD...

Embodiment 1

[0058] Take PDI (Silver Silver Light) 500 mass, add catalyst A two sub -phosphoric acid tetraolitic alcohol di kinds of 0.5 mass, heat it under the protection of nitrogen to 100 ° C, pre -reacting for 2h, nitrogen flow control to 50ml / min, and then Cooling to 50 ° C, the diluted PDI trimer catalyst, the temperature to 60 ° C, every 15 minutes test -NCO content, the NCO drops to 42.7 %, adds a mass of polymer neighboring, 1 mass, at 60 ° C, at 60 ° C At the temperature of 0.5h at the temperature, the antioxidant D D is 3,9-double [1, 1-two-based-2- [(3-unbardine-4-hydroxyl-5-methylphenyl) oblite oxygen Base] Acelis] -2, 4, 8, 10-tetra oxygen-oxygen [5.5] elevenane 0.5 quality portion, reaction 1h, stop reaction, ingredients to get PDI isocyanate composition E.

[0059]The diluted PDI trimer catalysts are prepared for: 2 catalyst catalysts of 0.1 quality portion are added to the three sibal acetate in the three scholarship, and the low temperature is stirred for 1h. The diluted PDI ...

Embodiment 2

[0062] Take PDI (Silver Silver Light) 500 mass, add 0.5 quality portion of pentaoltanoltanol di kinds of pentaoltanol in the catalyst, heat it under the protection of nitrogen to 100 ° C, pre -react 2h, nitrogen flow 50ml / min, and then cool down to 50 to 50 ° C, adding diluted PDI tritenuat catalysts to 60 ° C, testing every 15min -NCO content, NCO drops to 41.8 %, add 1 mass portion of the barrene neighboring toluene, Insulation 0.5h, antioxidant D is 3,9-double [1, 1-two-base-2- [(3-unitarine-4-hydroxyl-5-methaline) propyanohohol Base] -2, 4, 8, 10-tetraoxic snails [5.5] elevenane 0.5 mass, reaction 1h, stop reaction, ingredients get PDI isocyanate composition E;

[0063] The diluted PDI trimer catalysts are prepared for: 1 -quality acetate and 1 quality methanol with a catalyst of 0.1 mass catalyst and 1h. The diluted PDI trimer catalyst is added to the way to distribute a reaction bottle one by one. The drip speed is 5 drops / min, divided into three drops, each time the interva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com