Novel storage battery wiring terminal and manufacturing method thereof

The technology of a connection terminal and a manufacturing method, which is applied in the field of new battery connection terminals and its production, can solve the problems of complex production process and high material cost, achieve high material utilization rate, high production efficiency, and reduce the amount of mechanical processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

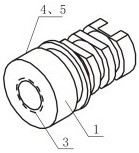

Image

Examples

Embodiment 1

[0030] A new type of battery terminal, the base material is 6xxx series aluminum alloy, and the 6xxx series aluminum alloy is composed of the following components in mass percentage: Mg: 0.5wt%, Si: 0.2wt%, Fe: 0.5wt%, Cu: 0.3 wt%, Mn: 0.4wt%, Cr: 0.1wt%, Ti: 0.12wt%, the content of other impurity elements ≤ 0.1wt%, and the rest is Al.

[0031] The manufacturing method of the above-mentioned novel storage battery terminal comprises the following steps:

[0032] 1) Terminal material: use the above-mentioned 6xxx series aluminum alloy as the terminal material;

[0033] 2) Preparation of terminal die-casting parts: Melt the terminal material at a temperature of 600°C, press the molten aluminum alloy into the cavity of the terminal mold at a filling speed of 70m / s under 90Mpa, under the action of pressure cooling and solidification to form castings;

[0034] 3) Mechanical processing of terminal die castings: according to the actual structure of different terminal blocks, the cas...

Embodiment 2

[0039] A new type of battery terminal, the base material is 6xxx series aluminum alloy, and the 6xxx series aluminum alloy is composed of the following components in mass percentage: Mg: 1.3wt%, Si: 1.3wt%, Fe: 0.2wt%, Cu: 0.7 wt%, Mn: 0.2wt%, Cr: 0.2wt%, Ti: 0.03wt%, the content of other impurity elements is ≤0.1wt%, and the rest is Al.

[0040] The manufacturing method of the above-mentioned novel storage battery terminal comprises the following steps:

[0041] 1) Terminal material: use the above-mentioned 6xxx series aluminum alloy as the terminal material;

[0042] 2) Preparation of terminal die-casting parts: Melt the terminal material at a temperature of 700°C, press the molten aluminum alloy into the cavity of the terminal mold at a filling speed of 80m / s under 80Mpa, under the action of pressure cooling and solidification to form castings;

[0043] 3) Mechanical processing of terminal die castings: according to the actual structure of different terminal blocks, the c...

Embodiment 3

[0048] A new type of battery terminal, the base material is 6xxx series aluminum alloy, and the 6xxx series aluminum alloy is composed of the following components in mass percentage: Mg: 0.8wt%, Si: 1wt%, Fe: 0.4wt%, Cu: 0.5wt% %, Mn: 0.3wt%, Cr: 0.1wt%, Ti: 0.12wt%, the content of other impurity elements ≤ 0.1wt%, and the rest is Al.

[0049] The manufacturing method of the above-mentioned novel storage battery terminal comprises the following steps:

[0050] 1) Terminal material: use the above-mentioned 6xxx series aluminum alloy as the terminal material;

[0051] 2) Preparation of terminal die-casting parts: Melt the terminal material at a temperature of 700°C, press the molten aluminum alloy into the cavity of the terminal mold at a filling speed of 75m / s under 85Mpa, under the action of pressure cooling and solidification to form castings;

[0052] 3) Mechanical processing of terminal die castings: according to the actual structure of different terminal blocks, the cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com