Injection molding process parameter optimization method for transparent complex multi-cavity plastic part

A technology for process parameter optimization and process parameter application in design optimization/simulation, CAD numerical modeling, special data processing applications, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

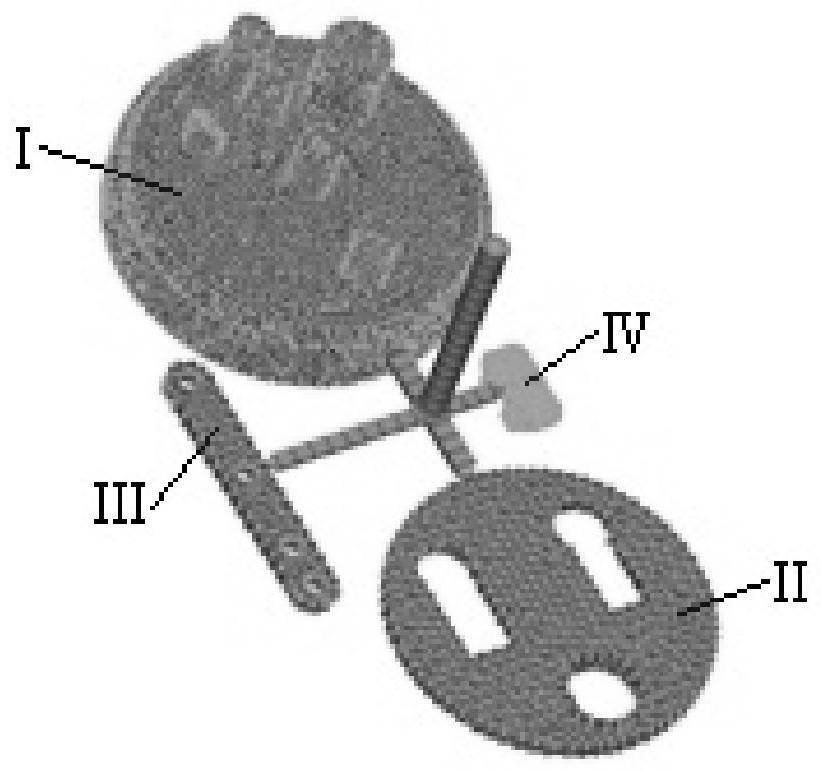

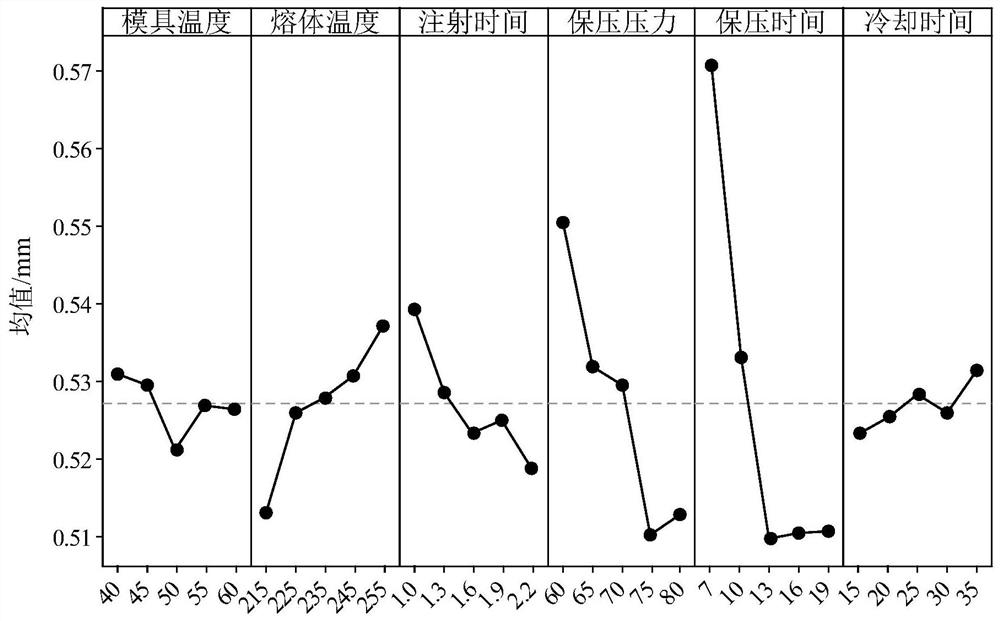

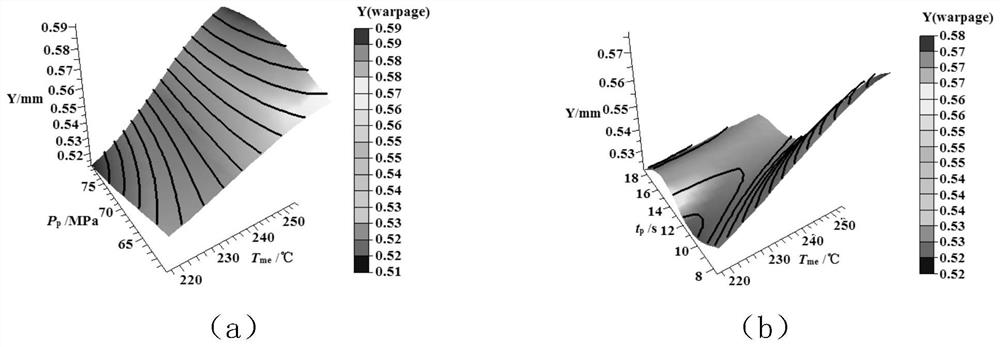

[0031] The method for optimizing injection molding process parameters of transparent and complex multi-cavity plastic parts adopts the combination of orthogonal test, Kriging model and optimization algorithm to optimize injection molding process parameters. The specific optimization process is as follows: Figure 14 As shown, firstly, based on the CAE simulation results, the orthogonal test design is carried out and the main factors affecting the warping deformation are screened out; on this basis, the Kriging model is established to map the nonlinear function relationship between the main factors and the optimization target; considering the correlation function For the impact on the Kriging model, select different correlation functions to establish the Kriging model and compare the accuracy; use numerical optimization algorithms, direct search methods and global exploration methods to optimize the established high-precision models, and select the most effective optimization te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com