Large-mode-field triple-clad optical fiber, preparation method thereof and optical fiber laser

A three-cladding, large mode field technology, applied in the optical field, can solve the problems of low melting point, difficult to meet user needs, transmission efficiency and negative impact on stability, etc., achieve high uniformity doping, improve transmission efficiency and stability. , to ensure full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a large mode field triple-clad optical fiber comprising the following steps:

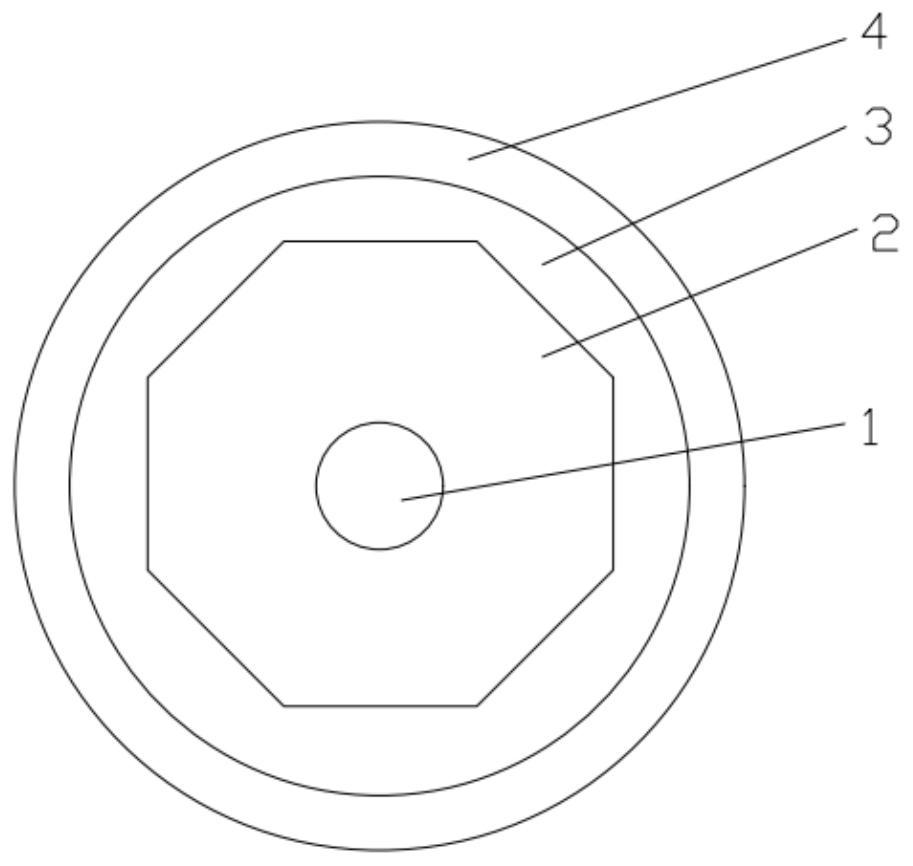

[0037] 1) preparing a porous glass core rod doped with a co-blend and then sintered as the fiber core 1;

[0038] 2) preparing a porous glass sleeve doped with germanium oxide and / or ammonium hexafluorosilicate and then sintered as the first cladding layer 2;

[0039] 3) Preparing heavily doped ammonium hexafluorosilicate and then sintering the porous glass casing as the second cladding 3;

[0040] 4) The large mode field triple-clad optical fiber can be obtained by high-temperature melting drawing by the casing method.

[0041] The present invention also provides a fiber laser using the above-mentioned large-mode-field triple-clad fiber as an output fiber.

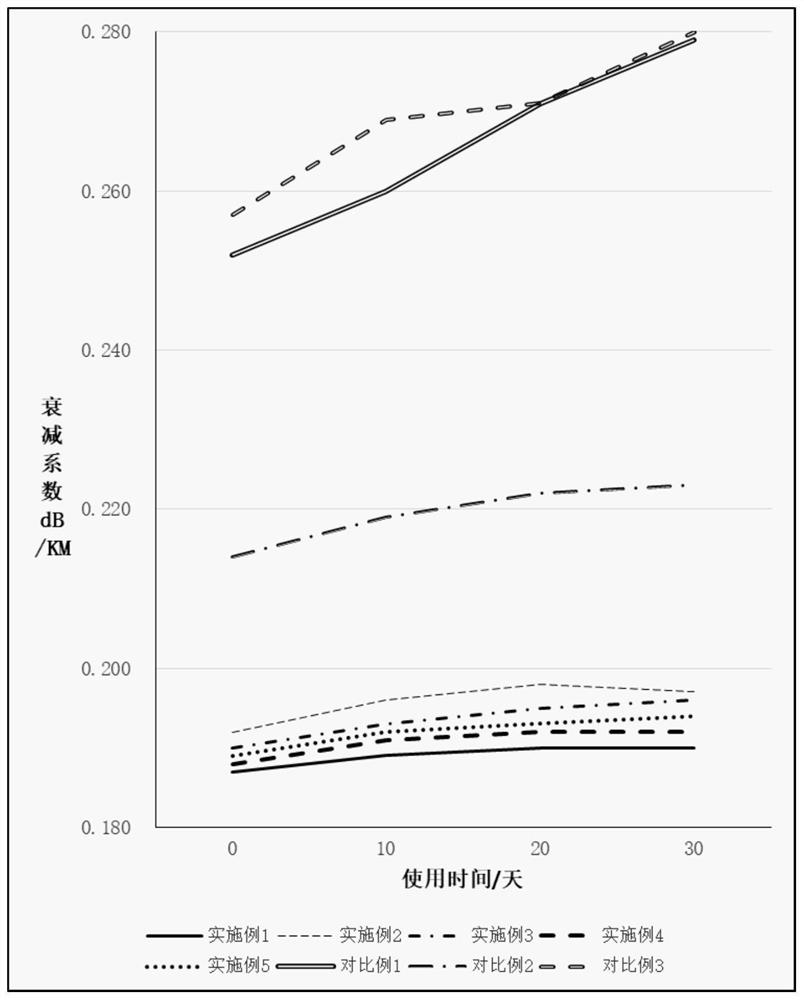

[0042] The above is the general idea of the present invention, and some also provide detailed examples and comparative examples to further illustrate the present invention. ...

Embodiment 1

[0044] In this embodiment, the fiber core is sintered porous glass doped with ytterbium chloride, aluminum chloride, ammonium dihydrogen phosphate, and cerium nitrate; the dopant , especially the high-concentration and high-uniformity distribution doping of rare earth ions, among which, the doping concentration of ytterbium ions is 20000ppm, the doping concentration of aluminum ions is 10000ppm, the doping concentration of phosphorus ions is 5000ppm, and the doping concentration of cerium ions The concentration is 3000ppm.

[0045] The first cladding layer is sintered porous glass doped with a small amount of germanium oxide (800ppm), and the second cladding layer is sintered porous glass heavily doped with ammonium hexafluorosilicate (20000ppm).

[0046] In this embodiment, the preparation method of the large mode field triple-clad optical fiber is as follows:

[0047] 1) Prepare a porous glass core rod with a diameter of 8mm as the fiber core according to the above formula;...

Embodiment 2

[0052] In this embodiment, the fiber core is sintered porous glass doped with ytterbium chloride, aluminum chloride, ammonium dihydrogen phosphate, cerium nitrate, and ammonium hexafluorosilicate; Features It can realize doping with high concentration and high uniformity distribution of dopants, especially rare earth ions, among which, the doping concentration of ytterbium ions is 26000ppm, the doping concentration of aluminum ions is 8000ppm, and the doping concentration of phosphorus ions is 8000ppm , the doping concentration of cerium ions is 3000ppm, and the doping concentration of fluorine ions is 3000ppm.

[0053]The first cladding layer is sintered porous glass doped with a small amount of ammonium hexafluorosilicate (900ppm), and the second cladding layer is sintered porous glass heavily doped with ammonium hexafluorosilicate (22000ppm).

[0054] In this embodiment, the preparation method of the large mode field triple-clad optical fiber is as follows:

[0055] 1) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com