Single-alloy double-performance turbine disc of aero-engine and preparation method of single-alloy double-performance turbine disc

An aero-engine, dual-performance technology, used in engine components, machines/engines, turbines, etc., can solve problems such as difficult control and complex preparation processes, and achieve good room temperature tensile properties, superior high temperature properties, high temperature creep resistance Excellent variable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also proposes a method for preparing a single-alloy dual-performance turbine disk for an aero-engine, comprising:

[0030] S1: Construct a 3D model of a single-alloy dual-performance turbine disk using 3D graphics software;

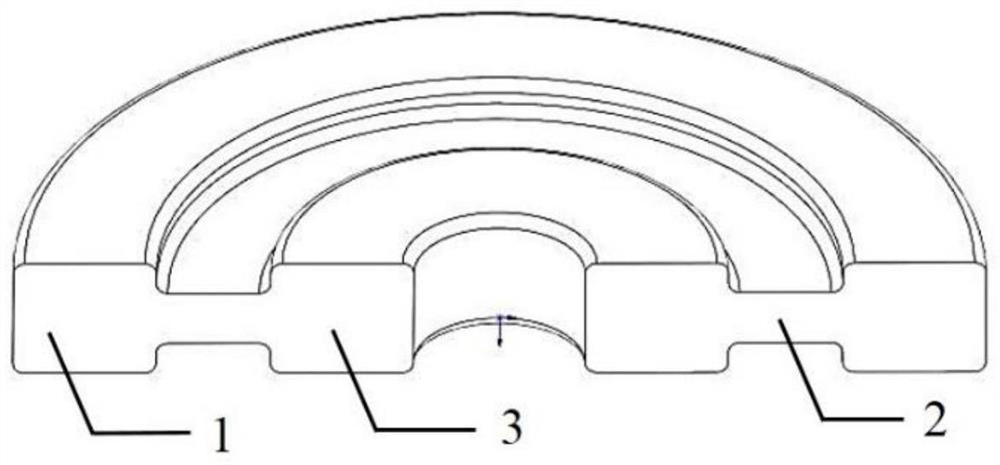

[0031] S2: Divide the 3D model from the side near the turbine shaft outwards into the core area, the web area and the disk edge area, and mark the area on the 3D model, as shown in figure 1 shown;

[0032] S3: Use layering software to cut and layer the 3D model after region marking along the height direction to obtain N slice models; each slice model contains region marks;

[0033] Preferably, in step S3, the thickness of the sheet model is 50-150 μm, and the degree of melting of each layer is controlled by controlling the thickness of the sheet, so that each layer reaches an optimal melting state.

[0034] S4: Along the height direction of the three-dimensional model, starting from the lowest layer model, the electron beam ...

Embodiment 1

[0067] This embodiment provides an aero-engine single-alloy dual-performance turbine disk, which is composed of TiAl alloy; the single-alloy dual-performance turbine disk includes a disk core, a web and a disk edge from the side near the turbine shaft to the outside, and the disk core is double-state tissue, the disc edge is a full-thickness sheet tissue, and the radial plate is a transition state between a two-state tissue and a full-thickness sheet tissue.

[0068] This embodiment also provides a method for preparing the above-mentioned single-alloy dual-performance turbine disk, including:

[0069] S1: Construct a 3D model of a single-alloy dual-performance turbine disk using the 3D graphics software Magics;

[0070] S2: Divide the three-dimensional model from the side near the turbine shaft outward into the core area, the web area and the flange area, and mark the area on the three-dimensional model, and then save it as a file with the suffix .stl;

[0071] S3: Import the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com