A construction method for high-stability anti-collapse cement pavement

A technology of cement pavement and construction method, which is applied to cohesive pavement paved on site, roads, roads, etc., which can solve the problems of low connection strength of concrete layers, short service life of pavement, high maintenance cost, etc., and reduce subsidence probability, high pavement strength, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

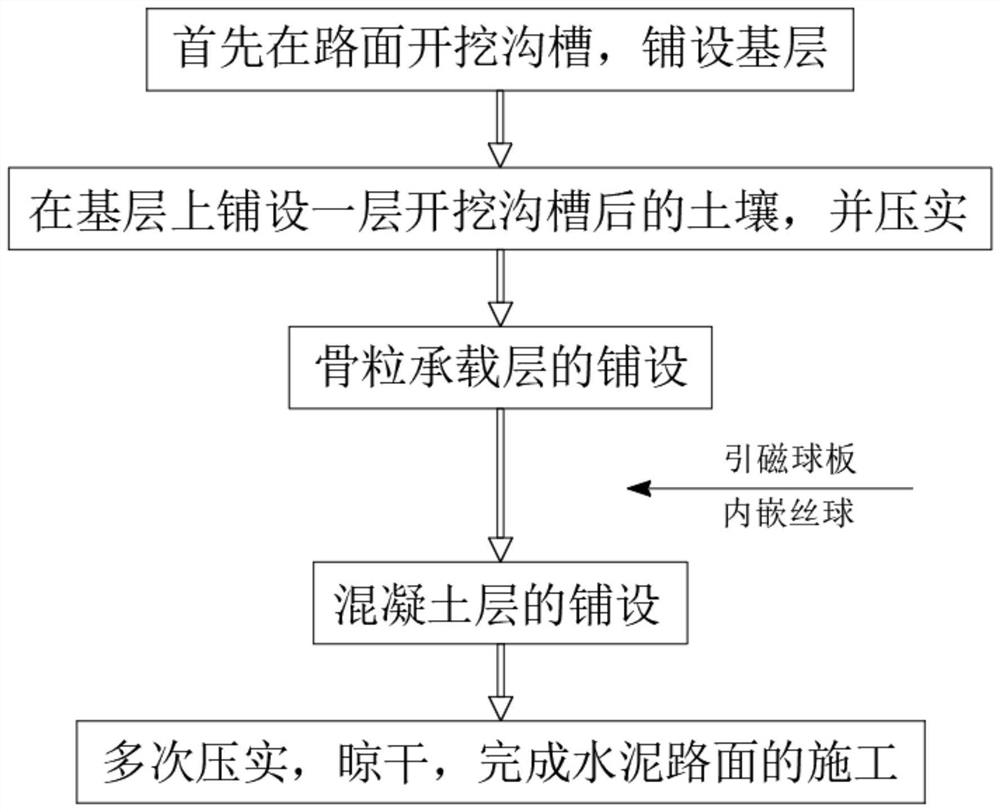

[0048] see figure 1 , a high stability anti-collapse cement pavement construction method, comprising the following steps:

[0049] S1. First, excavate trenches on the road surface and lay the base layer;

[0050] S2, then lay the soil after one deck excavation trench on the base, and compact, the thickness after compaction is 10-15cm;

[0051] S3, laying a mixture of stones and stones on the compacted soil surface, and then laying asphalt several times, and compacting to form a bone particle bearing layer;

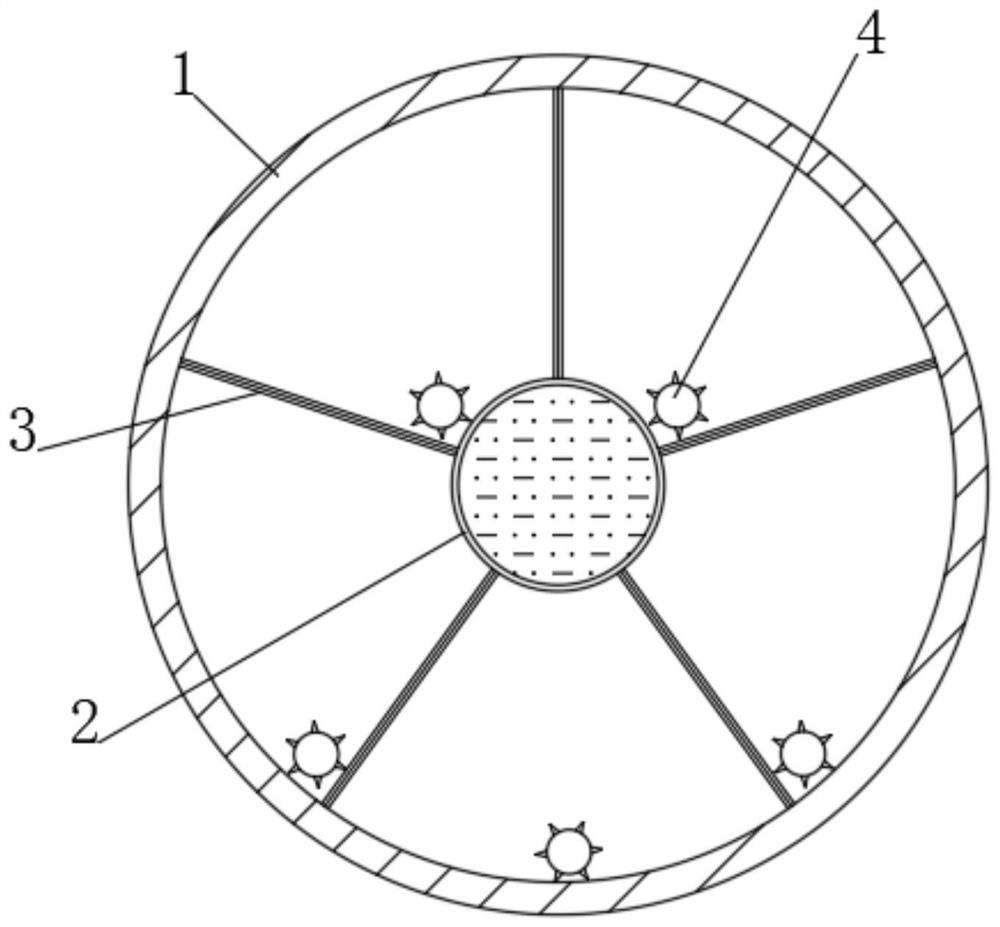

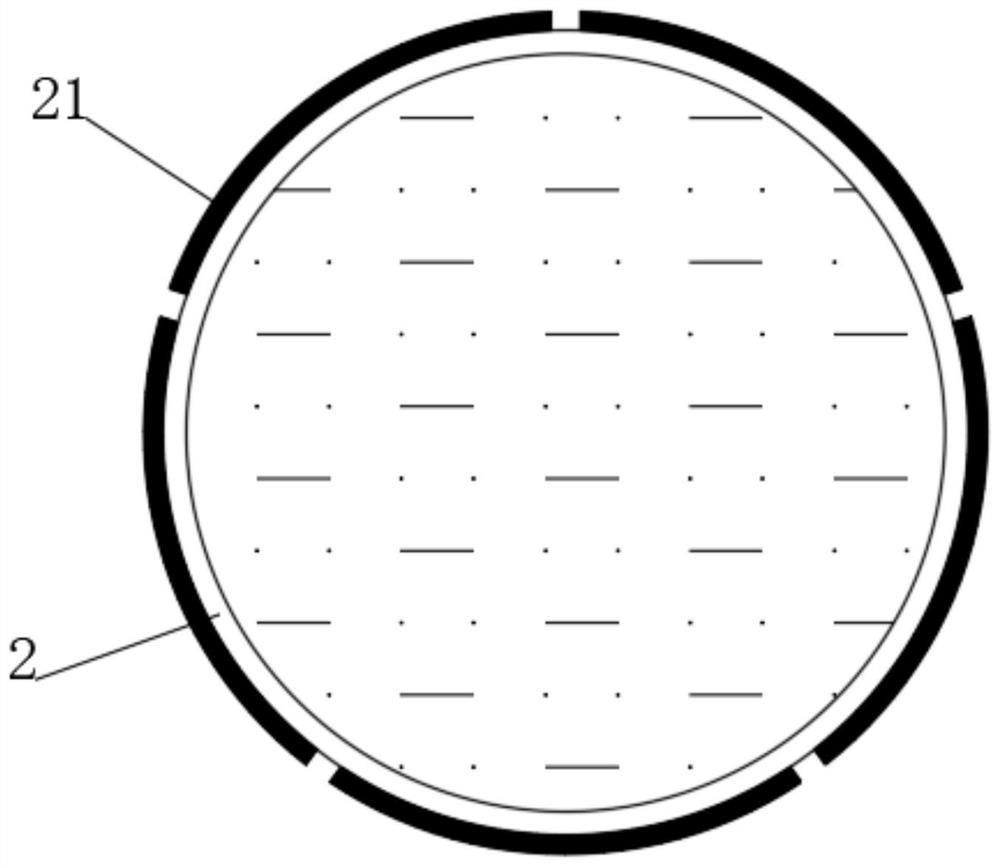

[0052] S4. Configure concrete slurry, and evenly mix and add embedded silk balls on the concrete slurry, then lay the concrete slurry on the bone particle bearing layer, vibrate through the vibrating rod, reduce the gap on the concrete slurry, and then The ball magnetic plate is continuously moved on the upper surface of the concrete slurry, and the vertical and horizontal distances are constantly changed during the movement, driving the micro-vibration of the embedded s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com