Preparation method of polycarbosilane ceramic precursor material

A technology of ceramic precursor and polycarbosilane, which is applied in the direction of additive processing, textile and papermaking, fiber chemical characteristics, etc., can solve problems such as difficult to guarantee polycarbosilane, achieve high pass rate of process, reduce production cost, and equipment and the effect of low process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] refer to Figure 4 , Figure 5 , Figure 6 and Figure 7 , a polycarbosilane ceramic precursor material preparation method, comprising the following steps:

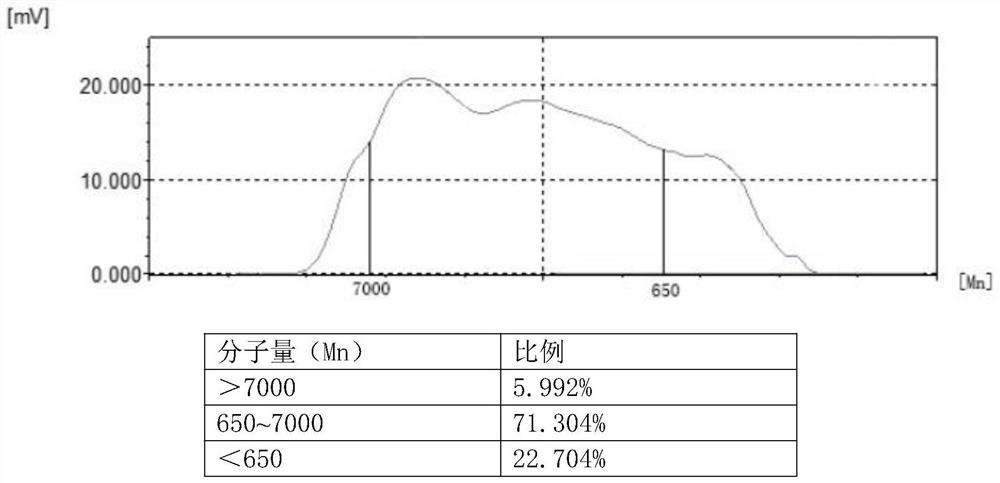

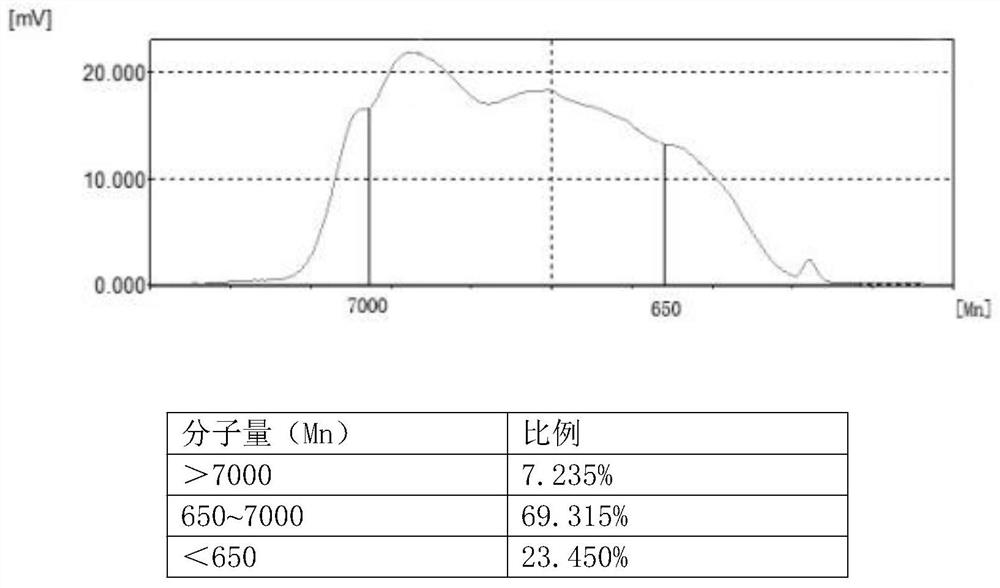

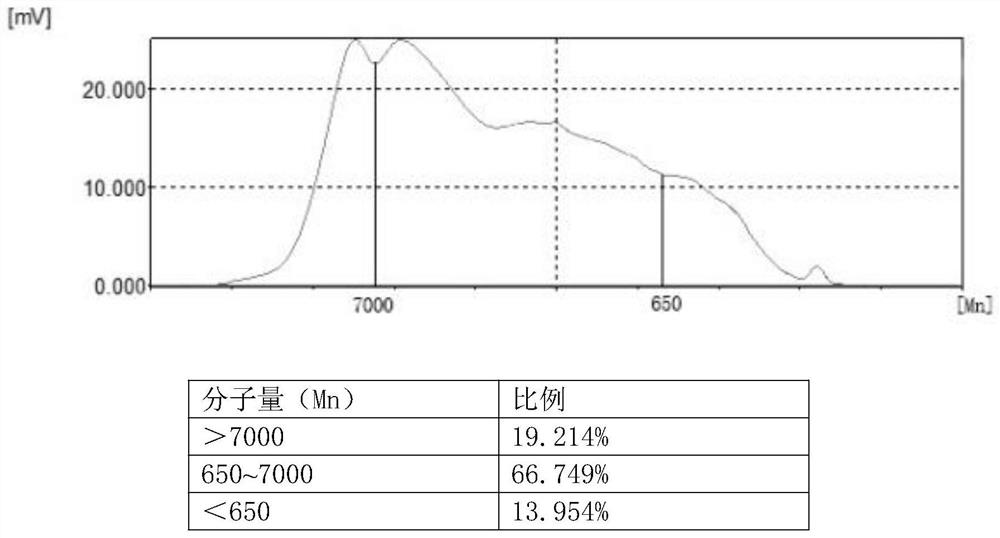

[0044] (1) Put polydimethylsilane in a high-pressure synthesis kettle, repeatedly evacuate and replace the gas in the kettle with high-purity nitrogen, and circulate nitrogen, control the temperature at 380°C±5°C, and keep the polydimethylsilane under normal pressure. Carbosilane cracking for 2 hours, then add nitrogen to keep the pressure at 0.5Mpa, continue to heat up to 440°C, react for 6 hours, control the pressure at (0.44-0.50)Mpa, and cool to obtain a polycarbonate with a softening point of 190-195°C Crude silane. Wherein, the obtained polycarbosilane crude product has a high molecular weight part of 6% to 8%, and a medium molecular weight part of 68% to 71%; the molecular weight distribution of the polycarbosilane crude product is shown in Figure 6 .

[0045] (2) Grinding the crude polycarbosilane, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com