Mineral slag micro-powder production line

A technology of slag micropowder and production line, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor drying effect of slag micropowder, shorten the time, improve the efficiency and effect, and prolong the contact time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

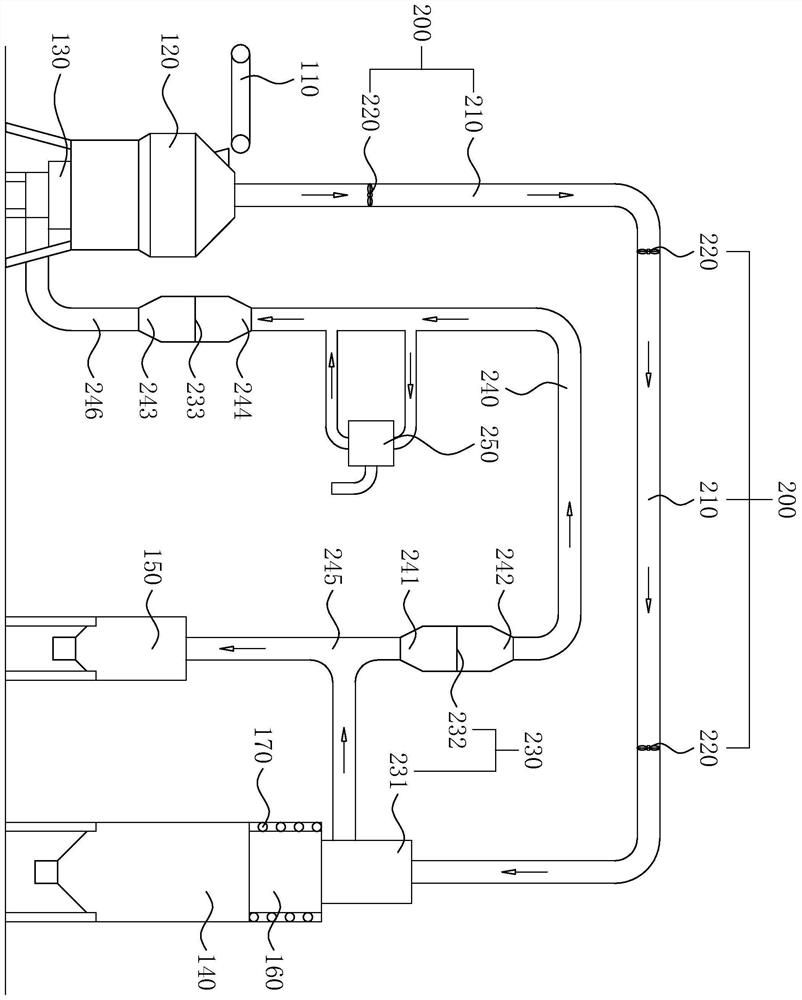

[0034] The following is attached figure 1 The application is described in further detail.

[0035] The embodiment of the present application discloses a slag fine powder production line. refer to figure 1 , the slag powder production line includes a feeding belt 110, a vertical mill 120, a hot gas furnace 130, a cooling bin 160, a finished product bin 140, a recovery bin 150 and an air delivery system 200; The feeding end of the feeder is connected, and the water slag can be transported to the vertical mill 120 through the feeding belt 110, and the vertical mill 120 grinds the water slag into slag powder. The gas outlet of the hot gas furnace 130 communicates with the gas inlet of the vertical mill 120. When the vertical mill 120 grinds water slag, the hot gas furnace 130 fills the vertical mill 120 with hot air to dry the slag powder.

[0036] The air delivery system 200 includes a feeding pipeline 210 and a filter system 230. The filtering system 230 includes a pulse dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com