Preparation method of super-hydrophobic-super-oleophylic straw felt for oil-water separation

An oil-water separation and superhydrophobic technology, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of easy to disperse superhydrophobic-superoleophilic straw fibers, superhydrophobic-superlipophilic failure, high price of silane, etc. problem, to achieve the effect of low raw material cost, low cost, and high-efficiency oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Take a few straw straws, cut them to a length of 10 mm, then soak them in an aqueous sodium hydroxide solution with a temperature of 80° C. and a mass fraction of 10% for 50 minutes. During the soaking process, the stirring speed is 600 r / min, and then pull them out. And rinse with water until neutral;

[0018] (2) pressing the treated rice straw into a round cake-shaped mold, drying and forming at 60°C;

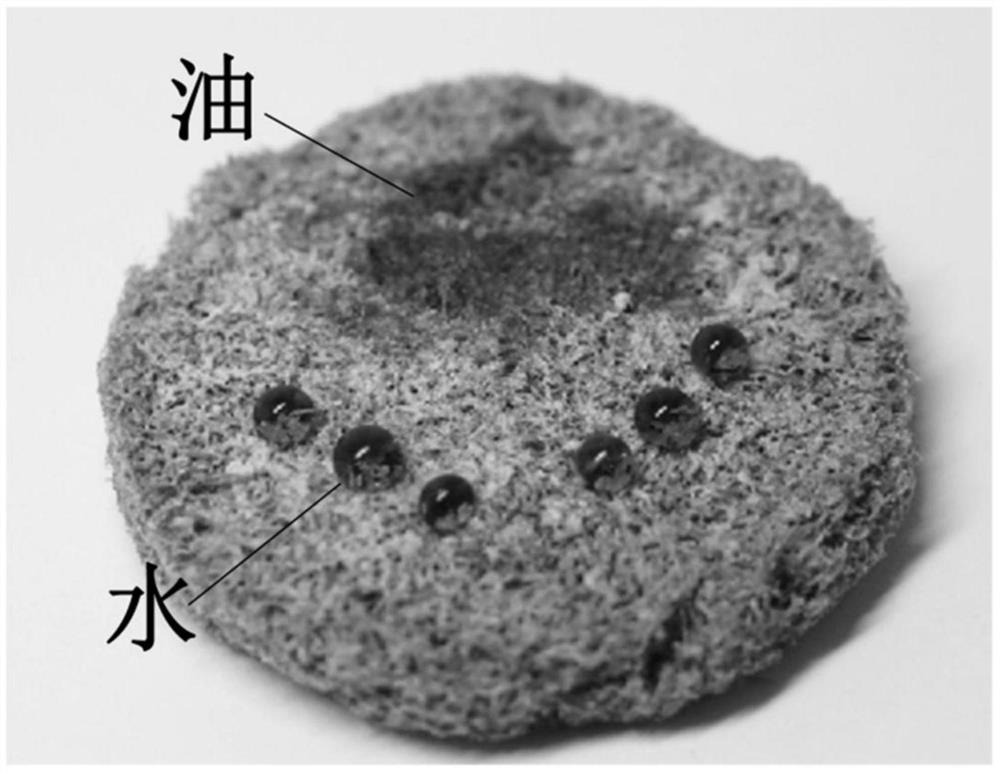

[0019] (3) Mix stearyl chloride and 1,4-anhydrous dioxane at a volume ratio of 1:20 to form a low surface energy solution, then soak the molded straw into the low surface energy solution for 30 minutes, and then remove out, and dried at 80°C, the straw obtained after drying was in the shape of a round cake, the contact angle to water was 155±1.8°, and the contact angle to oil was 0°, such as figure 1 shown.

[0020] (4) Put the straw treated with low surface energy into a round cake-shaped elastic porous cotton packaging bag with a pore size of 100 μm to obtain ...

Embodiment 2

[0022] (1) Take a few straw straws, cut them to a length of 30 mm, then soak them in an aqueous sodium hydroxide solution with a temperature of 80° C. and a mass fraction of 15% for 20 minutes. During the soaking process, the stirring speed is 500 r / min, and then pull them out. And rinse with water until neutral;

[0023] (2) pressing the treated rice straw into a cylindrical mold, drying and molding at 50°C;

[0024] (3) Mix stearyl chloride and 1,4-anhydrous dioxane at a volume ratio of 1:10 to form a low surface energy solution, then soak the molded straw into the low surface energy solution for 30 minutes, and then remove out, and dried at 70°C, the straw obtained after drying was cylindrical, the contact angle to water was 156±1.2°, and the contact angle to oil was 0°.

[0025] (4) Put the straw treated with low surface energy into a cylindrical elastic porous cotton packaging bag with a pore size of 200 μm to obtain a superhydrophobic-superoleophilic straw felt.

Embodiment 3

[0027] (1) Take a few straw straws, cut them to a length of 20 mm, then soak them in an aqueous sodium hydroxide solution with a temperature of 80° C. and a mass fraction of 12% for 40 minutes. During the soaking process, the stirring speed is 800 r / min, and then pull them out. And rinse with water until neutral;

[0028] (2) pressing the treated rice straw into a square mold, drying and molding at 40°C;

[0029] (3) Mix stearyl chloride and 1,4-anhydrous dioxane at a volume ratio of 1:5 to form a low surface energy solution, then soak the molded straw into the low surface energy solution for 20 minutes, and then remove out, and dried at 60°C, the straw obtained after drying was in the shape of a square, the contact angle to water was 154±0.9°, and the contact angle to oil was 0°.

[0030] (4) Put the low surface energy treated straw into a square-shaped elastic porous cotton packaging bag with a pore size of 300 μm to obtain a superhydrophobic-superoleophilic straw felt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com