Memory and forming method thereof

A memory and storage array technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of increasing process complexity and negative effects, and achieve improved metal distribution uniformity, increased process costs, and improved storage. effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the memory provided by the present invention and its forming method will be described in detail below in conjunction with the accompanying drawings.

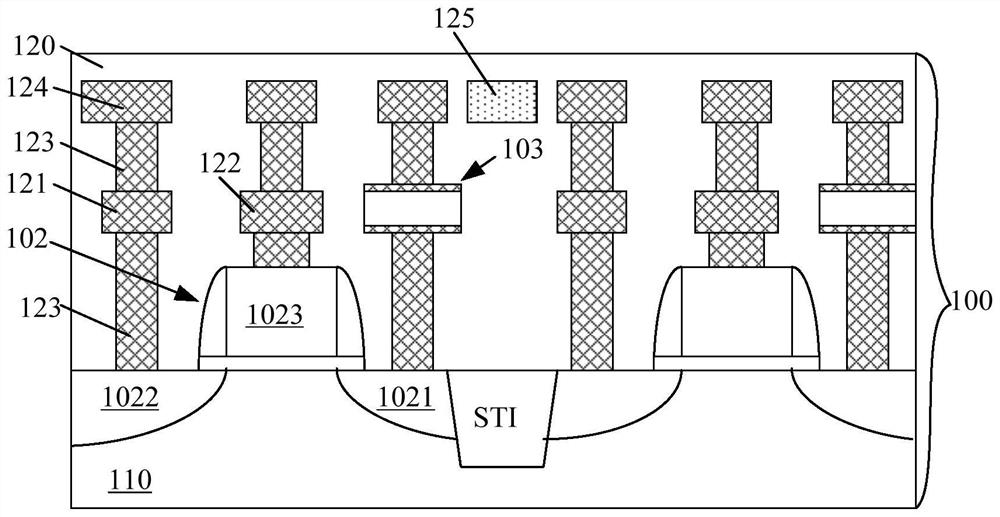

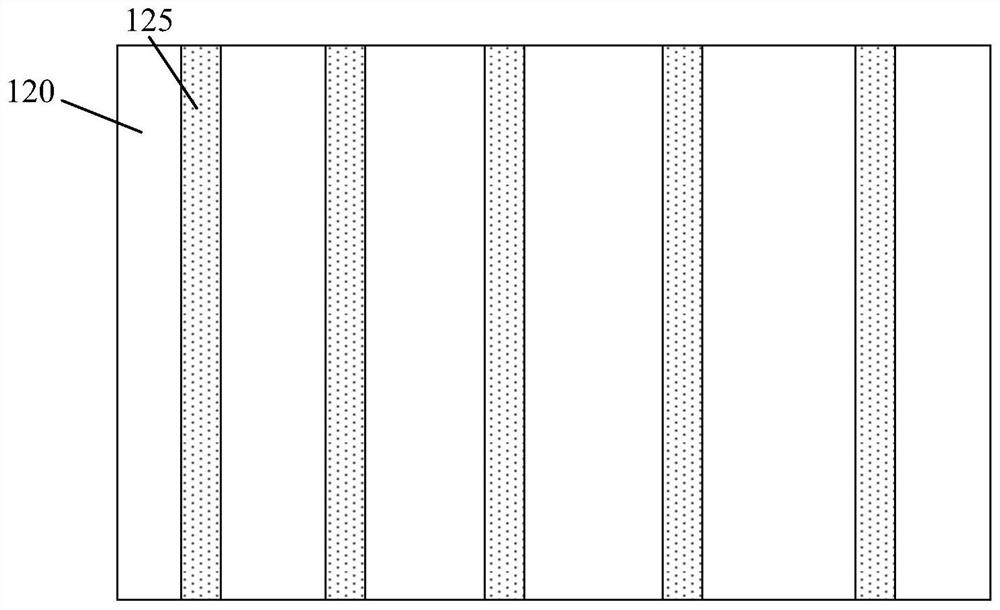

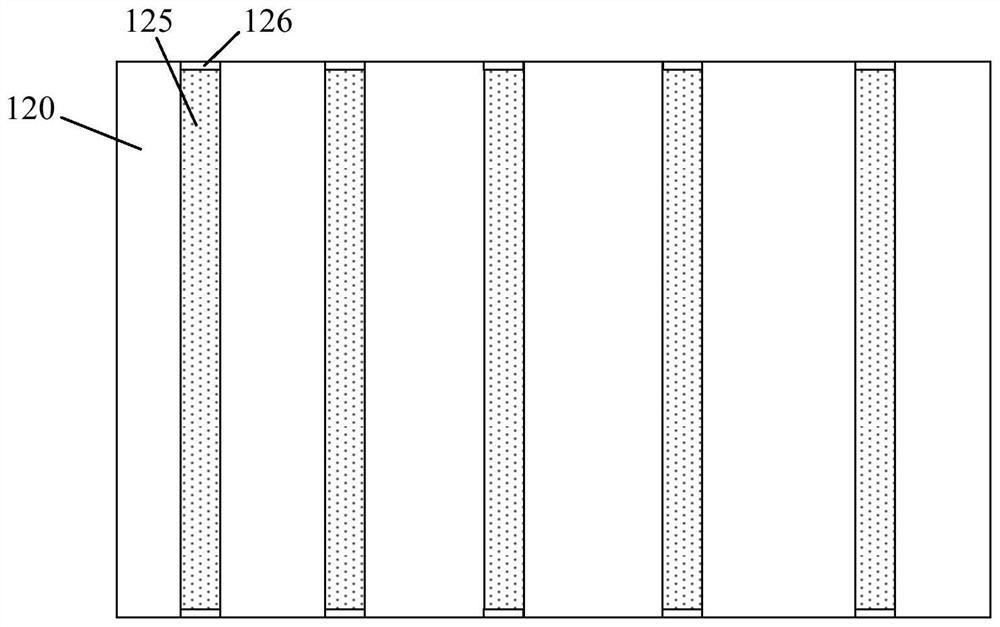

[0029] Please refer to Figure 1 to Figure 5 , is a structural schematic diagram of the formation process of the memory according to a specific embodiment of the present invention.

[0030] Please refer to figure 1 , providing a first substrate 100, the first substrate 100 includes a first substrate 110, a storage array formed on the front surface of the first substrate 110, and a first dielectric layer 120 covering the storage array.

[0031] The first substrate 110 is a semiconductor substrate, such as a single crystal silicon substrate, a silicon germanium substrate, a silicon-on-insulator substrate, and the like. The first substrate 110 has a shallow trench isolation structure (STI, Shallow Trench Isolation).

[0032] In this specific implementation manner, the storage array is a DRAM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com