A kind of anti-sulfide silver electrode slurry and preparation method thereof

A technology of electrode paste and silver sulfide, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as uneven mixing effects, product function problems, and abnormal resistance values , to achieve the effect of excellent printing performance, uniform slurry and strong anti-vulcanization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An embodiment of the anti-sulfide silver electrode slurry of the present invention, the anti-sulfide silver electrode slurry described in this embodiment is prepared by the following method:

[0026] (1) Dissolution of organic carrier: take by weighing 45% of hydrogenated terpineol, 30% of ethylene glycol butyl ether acetate, 1% of hydrogenated rosin, 23.5% of ethyl cellulose, and 0.5% of DLTP according to the following percentage by weight. Stir and dissolve in a water bath at 70°C for 2 hours to obtain an organic carrier;

[0027] (2) Production of slurry:

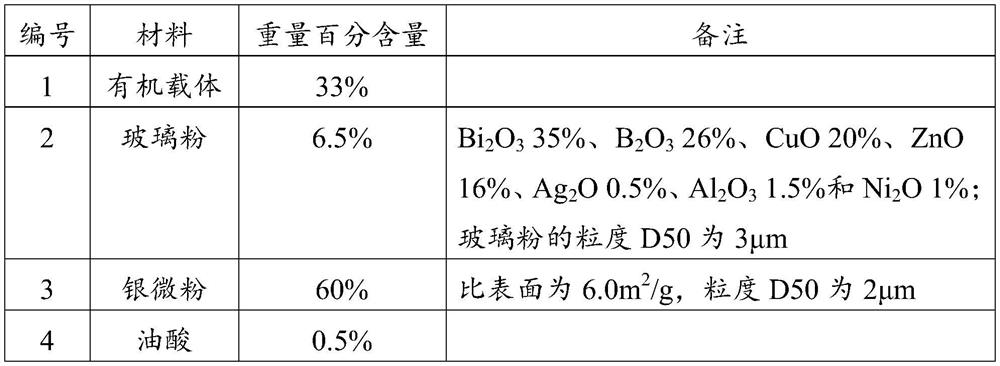

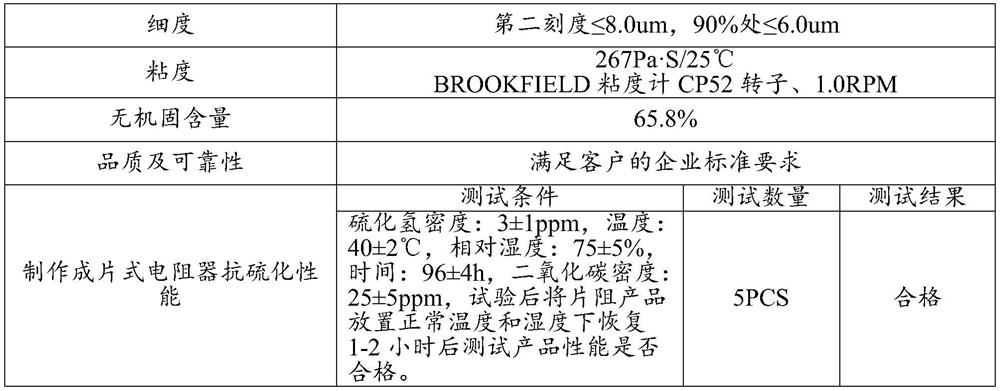

[0028] Design according to the parameters in Table 1:

[0029] Table 1

[0030]

[0031] According to the above formula, use a homogenizer to strengthen the dispersion, and then use a three-roll mill to grind 6-8 times. Among them, the oleic acid can be uniformly mixed with the solvent at a ratio of 1:3 and then fully homogeneously dispersed with the silver micropowder to obtain an anti-sulfide silver electro...

Embodiment 2

[0038] An embodiment of the anti-sulfide silver electrode slurry of the present invention, the anti-sulfide silver electrode slurry described in this embodiment is prepared by the following method:

[0039] (1) Dissolution of organic carrier: take by weight 52% of hydrogenated terpineol, 30% of ethylene di-DHTA, 1% of hydrogenated rosin, 16% of ethyl cellulose, and 1% of DLTP according to the following weight percentages, and place them in a water bath at a temperature of 80°C Stir and dissolve for 1.5 hours to obtain an organic vehicle;

[0040] (2) Production of slurry:

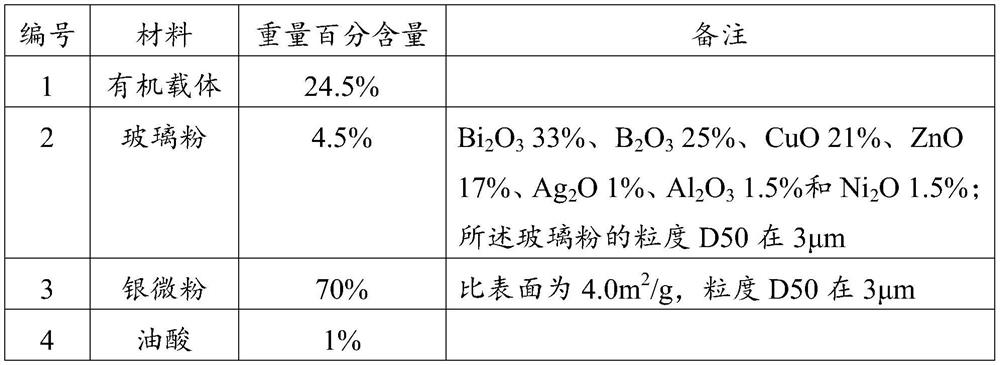

[0041] Design according to the parameters in Table 4:

[0042] Table 4

[0043]

[0044] Mix according to the formula, use a homogenizer to strengthen dispersion, and then use a three-roll mill to grind 6-8 times. Among them, the oleic acid can be uniformly mixed with the solvent at a ratio of 1:3 and then fully homogeneously dispersed with the silver micropowder; to obtain an anti-sulfide silver elect...

Embodiment 3

[0051] An embodiment of the anti-sulfide silver electrode slurry of the present invention, the anti-sulfide silver electrode slurry described in this embodiment is prepared by the following method:

[0052](1) Dissolution of organic carrier: take by weight 60% ethylene glycol butyl ether acetate, DHTA30%, hydrogenated rosin 1%, ethyl cellulose 7%, DLTP 2% according to the following percentage by weight, and put them in a water bath at 90°C stirring and dissolving in medium for 1 hour to obtain an organic carrier;

[0053] (2) Production of slurry:

[0054] Design according to the parameters in Table 7:

[0055] Table 7

[0056]

[0057] Mix according to the formula, use a homogenizer to strengthen the dispersion, and then use a three-roll mill to grind 6-8 times, wherein the oleic acid and the solvent are uniformly mixed according to the ratio of 1:3, and then fully and homogeneously dispersed with the silver micropowder to obtain an anti-sulfide silver electrode slurry. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com