Double-layer anti-oxidation bonding bottom layer high-temperature sealing coating and preparation method thereof

A technology for bonding the bottom layer and sealing the coating. It is applied in the direction of coating, metal material coating technology, and high-efficiency propulsion technology. Matching and other problems, to achieve the effect of increasing the bonding strength, small particle size of raw materials, and fine and dense tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

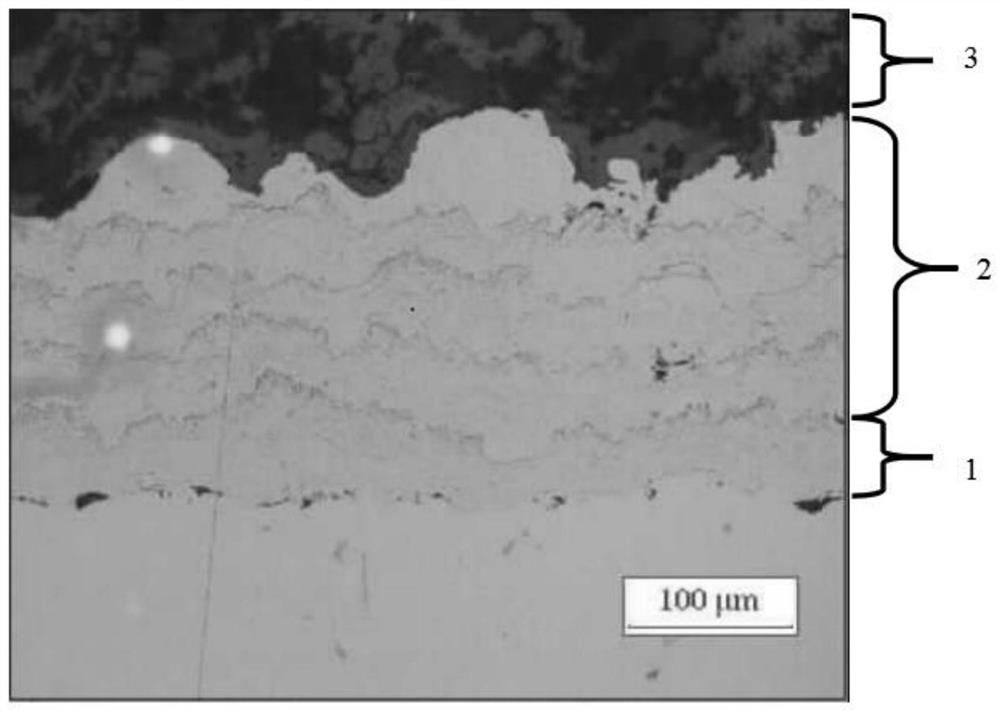

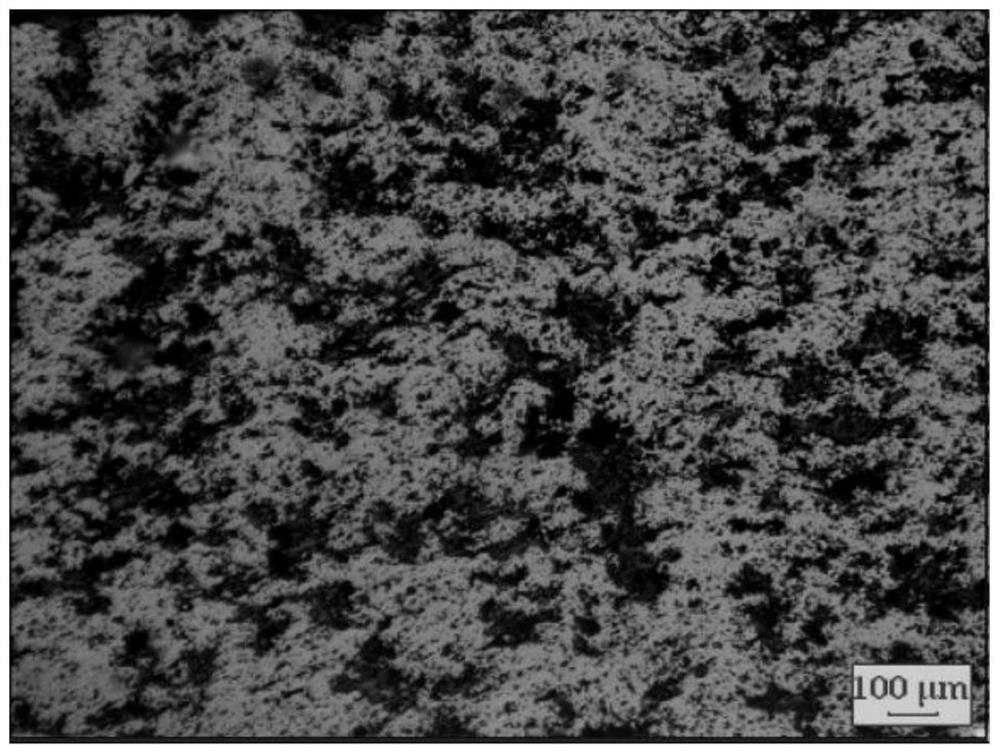

[0030]A double-layer anti-oxidation bonding primer high-temperature sealing coating, including CoNiCrAlY anti-oxidation primer, CoNiCrAlY intermediate bonding transition layer and ZrO 2 ·Y 2 o 3 Ceramic sealing layer;

[0031] The CoNiCrAlY anti-oxidation bottom layer has an element mass percentage of: Ni32%, Cr21%, Al8%, Y0.5%, and the balance is Co; the thickness of the CoNiCrAlY anti-oxidation bottom layer is 0.10mm; the structure of the CoNiCrAlY anti-oxidation bottom layer The porosity is 0.6%; the raw material of the CoNiCrAlY anti-oxidation bottom layer is Co32Ni21Cr8Al0.5Y powder with a particle size of 10 μm;

[0032] The CoNiCrAlY intermediate bonding transition layer, the element mass percentage is: Ni32%, Cr21%, Al8%, Y0.5%, the balance is Co; the thickness of the CoNiCrAlY intermediate bonding transition layer is 0.15mm; the CoNiCrAlY intermediate The tissue porosity of the bonding transition layer is 0.8%; the raw material of the CoNiCrAlY intermediate bonding...

Embodiment 2

[0045] A double-layer anti-oxidation bonding primer high-temperature sealing coating, including CoNiCrAlY anti-oxidation primer, CoNiCrAlY intermediate bonding transition layer and ZrO 2 ·Y 2 o 3 Ceramic sealing layer;

[0046] The CoNiCrAlY anti-oxidation bottom layer has an element mass percentage of: Ni32%, Cr21%, Al8%, Y0.5%, and the balance is Co; the thickness of the CoNiCrAlY anti-oxidation bottom layer is 0.08mm; the structure of the CoNiCrAlY anti-oxidation bottom layer The porosity is 0.65%; the raw material of the CoNiCrAlY anti-oxidation bottom layer is Co32Ni21Cr8Al0.5Y powder with a particle size of 25 μm;

[0047] The CoNiCrAlY intermediate adhesive transition layer has an element mass percentage of: Ni32%, Cr21%, Al8%, Y0.5%, and the balance is Co; the thickness of the CoNiCrAlY intermediate adhesive transition layer is 0.14mm; the CoNiCrAlY intermediate The tissue porosity of the bonding transition layer is 0.73%; the raw material of the CoNiCrAlY intermedi...

Embodiment 3

[0060] A double-layer anti-oxidation bonding primer high-temperature sealing coating, including CoNiCrAlY anti-oxidation primer, CoNiCrAlY intermediate bonding transition layer and ZrO 2 ·Y 2 o 3 Ceramic sealing layer;

[0061] The CoNiCrAlY anti-oxidation bottom layer has an element mass percentage of: Ni32%, Cr21%, Al8%, Y0.5%, and the balance is Co; the thickness of the CoNiCrAlY anti-oxidation bottom layer is 0.11 mm; the tissue pores of the CoNiCrAlY anti-oxidation bottom layer The ratio is 0.7%; the raw material of the CoNiCrAlY anti-oxidation bottom layer is Co32Ni21Cr8Al0.5Y powder with a particle size of 5.5 μm;

[0062] The CoNiCrAlY intermediate bonding transition layer, the element mass percentage is: Ni32%, Cr21%, Al8%, Y0.5%, the balance is Co; the thickness of the CoNiCrAlY intermediate bonding transition layer is 0.12mm; the CoNiCrAlY intermediate The tissue porosity of the bonding transition layer is 0.8%; the raw material of the CoNiCrAlY intermediate bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com