Modified sodium silicate grouting material

A technology of grouting material and modified water, which can be used in soil conditioning materials, organic fertilizers, fertilizer mixtures, etc., and can solve problems such as poor injectability, sand gushing, and unstable reinforcement effect.

Inactive Publication Date: 2020-12-08

BEIJING MUNICIPAL ROAD & BRIDGE

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traditional acid-sodium silicate slurry still has some disadvantages, such as poor injectability in dry silty sand formations with loose and poor stability, resulting in unstable reinforcement effect and unsatisfactory anti-seepage effect

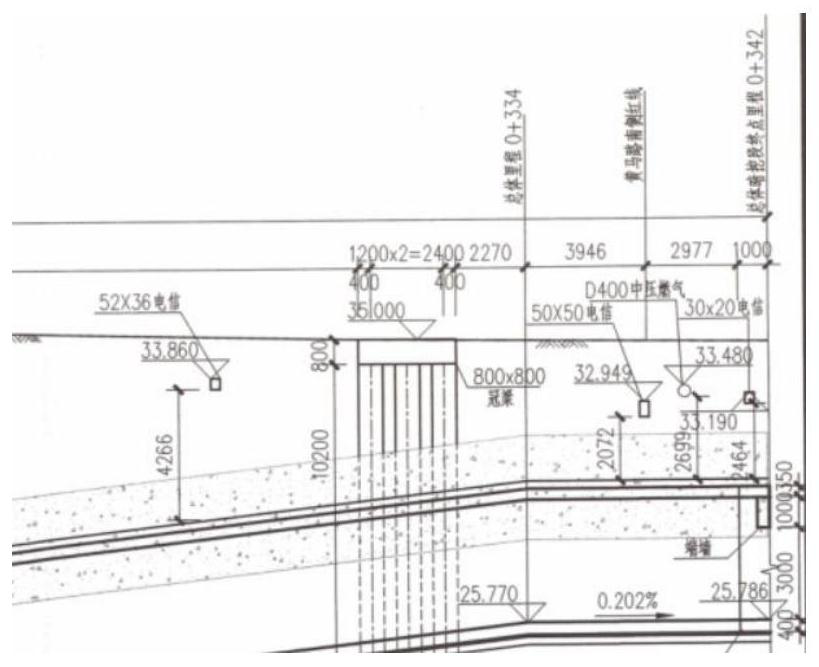

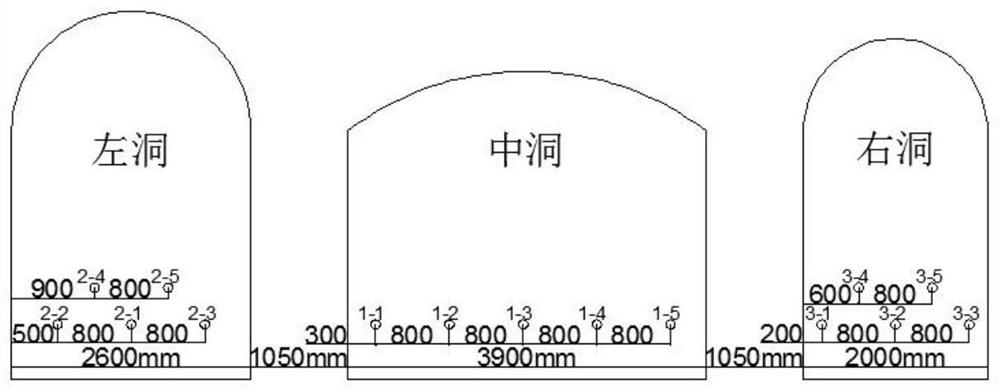

Taking the Beijing Underground Comprehensive Pipe Gallery Project as an example, the use of traditional acid water glass grouting materials is prone to sand leakage, sand gushing, and massive settlement, which will seriously affect the construction progress and cause economic losses

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a modified sodium silicate grouting material which comprises a liquid A and a liquid B which are uniformly mixed. The solution A is a phosphoric acid solution, the solution B is a sodium silicate solution and a surfactant, and the specific ratio is as shown in the specification; compared with acid-sodium silicate double-liquid slurry, the anionic surfactant is added, so that the wetting permeability of the sodium silicate solution is improved to a greater extent, and the surface tension of the sodium silicate solution is reduced. After the anionic surfactant is added, ahydrophobic alkyl chain of the anionic surfactant is adsorbed on the surface of sandy soil, and a hydrophilic group with a benzene ring tilts to a water phase, so that the surface tension of water and the liquid-solid interfacial tension of the sandy soil are reduced, the contact angle of water on the surface of the sandy soil is decreased, the surface property of the sandy soil is changed from hydrophobicity to hydrophilicity, and the sandy soil wetting performance of a solution is enhanced; therefore, the permeation range of the sodium silicate slurry in a soil layer during rock-soil grouting reinforcement can be enlarged, the grouting time is shortened, and the grouting pressure is reduced. The modified sodium silicate grouting material has wide development and application prospects indry silty-fine sand stratums.

Description

technical field [0001] The invention relates to a modified water glass grouting material, which belongs to the field of stratum reinforcement and water blocking and anti-seepage grouting materials. Background technique [0002] The grouting theory is developed based on fluid mechanics and solid mechanics. By analyzing the flow form of grout, the relationship between grouting pressure, grout flow rate, diffusion radius and grouting time is established. The grouting theory can be used to study the flow laws of different types of grout in rock and soil pores, reveal the relationship between formation characteristics, material properties and grouting process parameters, and provide scientific basis and theoretical guidance for grouting design and construction. For different engineering problems, the currently developed grouting theories mainly include permeable grouting, splitting grouting, compaction grouting, electro-chemical grouting, and low-permeability medium grouting theo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K17/40C09K103/00

CPCC09K17/40C09K2103/00

Inventor 宣恒苏磊田秋怀孙大伟刘佳杰宁伟

Owner BEIJING MUNICIPAL ROAD & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com