Tar processing production line and assay instrument cleaning and drying device

A drying device and instrument technology, applied in heating devices, chemical instruments and methods, drying solid materials, etc., to achieve good effect, long service life, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

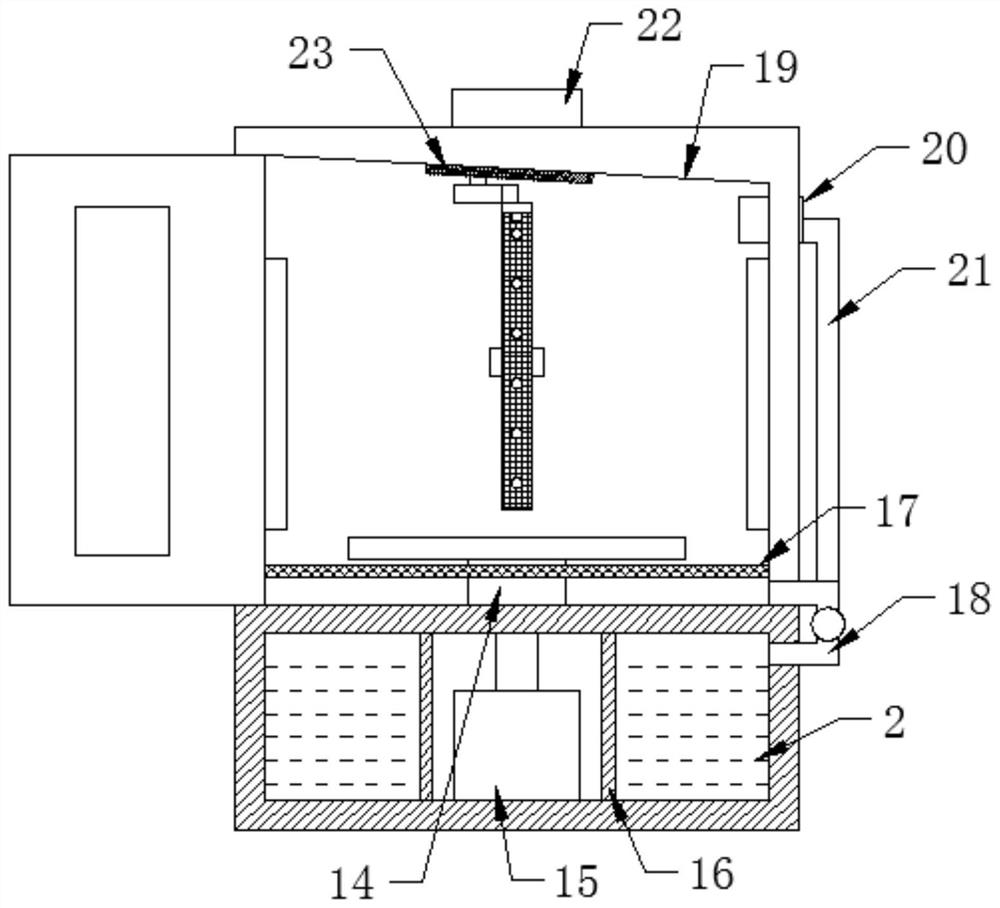

[0033] see Figure 1-4 , the present invention provides a technical solution: a cleaning and drying device for laboratory instruments, comprising a barrel body 1, the barrel body 1 is fixed on the water tank seat 2, the inner cavity of the barrel body 1 is provided with an instrument fixing seat 3, and the inside of the water tank seat 2 A driver 7 is installed, the output end of the driver 7 is connected to the bottom of the instrument holder 3, and the instrument located on the instrument holder 3 can be driven to adjust the position through the driver 7, so that when cleaning and drying, by cleaning the brush plate 4 and the heater 5 ensure the cleaning and drying effect. One side of the inner wall of the barrel body 1 is connected with the cleaning brush plate 4 through the adjustment mechanism 6, and the cleaning brush plate 4 can be adjusted to a suitable position through the adjustment mechanism 6 to ensure that the instrument is driving Driven by part 7, it can ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com