Method for preparing cotton stalk bark microcrystalline cellulose/graphene oxide aerogel fiber

A technology of alkene aerogel fiber and microcrystalline cellulose is applied in the field of preparing cotton stalk skin microcrystalline cellulose/graphene oxide aerogel fiber, which can solve problems such as resource waste and environmental pollution, and achieve short mass transfer distance. , Solve the difficulty of easy agglomeration and recycling, and the effect of large specific surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

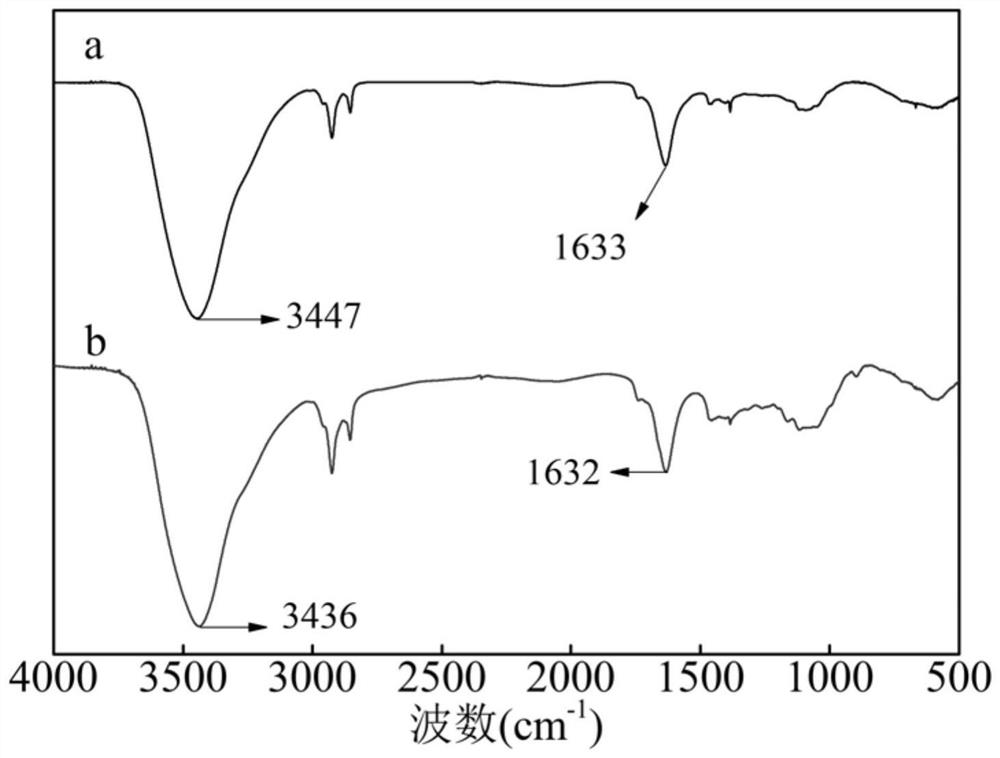

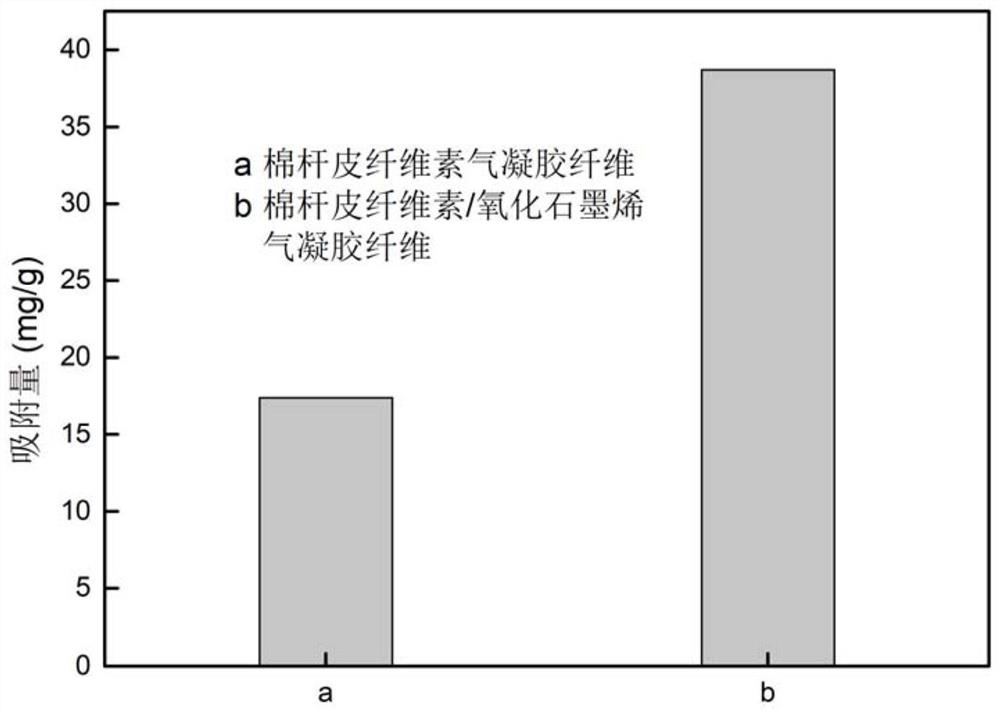

[0030] The preparation method of the cotton stalk bark microcrystalline cellulose airgel fiber in the present embodiment comprises the following steps:

[0031] (1) Dissolving: add cotton stalk husk microcrystalline cellulose (prepared by referring to the method in Example 1 in Patent No. 201710847371.7) to the melted 1-butyl 2-methylimidazolium chloride salt, and the cotton stalk husk is slightly The mass ratio of crystalline cellulose to 1-butyl 2-methylimidazolium chloride salt is 3:100, keep the temperature at 80°C and continue to stir for 2 hours to dissolve the solution;

[0032] (2) Add dimethyl sulfoxide to the dissolving solution in step (1) to obtain cotton stalk bark microcrystalline cellulose spinning solution; wherein the quality of dimethyl sulfoxide is 1-butyl 2-methylimidazole 50% of the mass ratio of chlorine salt;

[0033] (3) Degassing: the cotton stalk skin microcrystalline cellulose spinning solution obtained in step (2) was continuously stirred for 3 hou...

Embodiment 2

[0040] The preparation method of the cotton stalk bark microcrystalline cellulose / graphene oxide airgel fiber in the present embodiment comprises the following steps:

[0041] (1) Dissolving: add cotton stalk husk microcrystalline cellulose (prepared by referring to the method in Example 1 in Patent No. 201710847371.7) to the melted 1-butyl 2-methylimidazolium chloride salt, and the cotton stalk husk is slightly The mass ratio of crystalline cellulose to 1-butyl 2-methylimidazolium chloride salt is 3:100, and the temperature is kept at 80° C. and stirred for 2 hours to obtain a solution;

[0042] (2) Composite: use an ultrasonic disperser to disperse graphene oxide with a specification of 0.5 to 4 nm evenly in dimethyl sulfoxide, and then add the graphene oxide and dimethyl sulfoxide mixture to the step (1 ) in the solution to obtain cotton stalk skin microcrystalline cellulose / graphene oxide spinning solution; wherein the quality of graphene oxide is 4% of the cotton stalk sk...

Embodiment 3

[0050] The preparation method of the cotton stalk bark microcrystalline cellulose / graphene oxide airgel fiber of the present embodiment comprises the following steps:

[0051] (1) Dissolving: add cotton stalk husk microcrystalline cellulose (prepared by referring to the method in Example 1 in Patent No. 201710847371.7) to the melted 1-butyl 2-methylimidazolium chloride salt, and the cotton stalk husk is slightly The mass ratio of crystalline cellulose to 1-butyl 2-methylimidazolium chloride salt is 3:100, and the temperature is kept at 80° C. and stirred for 2 hours to obtain a solution;

[0052] (2) Composite: use an ultrasonic disperser to disperse graphene oxide with a specification of 0.5 to 4 nm evenly in dimethyl sulfoxide, and then add the graphene oxide and dimethyl sulfoxide mixture to the step (1 ) in the solution to obtain cotton stalk skin microcrystalline cellulose / graphene oxide spinning solution; wherein the quality of graphene oxide is 6% of the quality of cott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com