A kind of technology based on medical tablet coating processing

A coating and tablet technology, applied in the direction of making medicines into special physical or taking forms of devices, coatings, etc., can solve the problems of poor moisture-proof and anti-oxidation effects, difficult to achieve moisture-proof and anti-deterioration, and long drying time. , to achieve the effect of easy drying, avoiding stomach discomfort and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

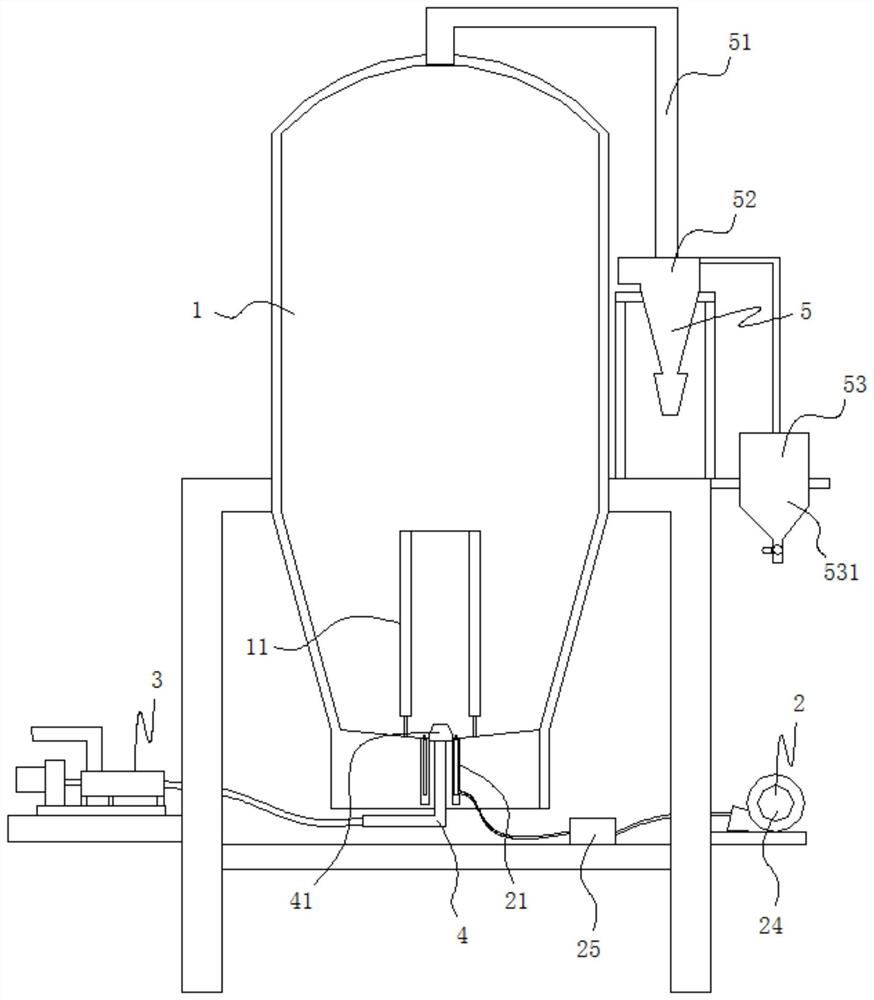

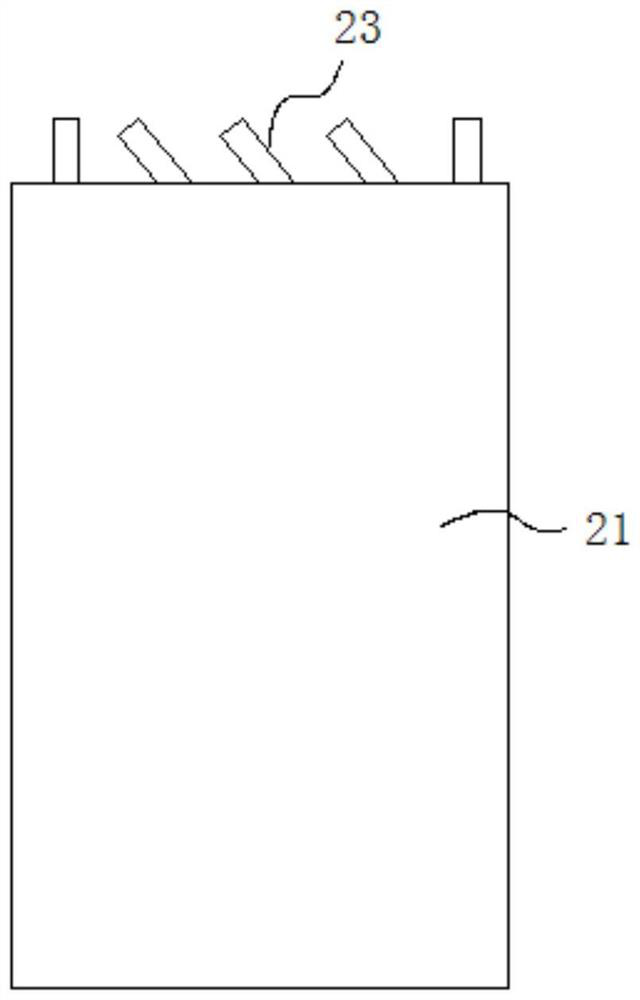

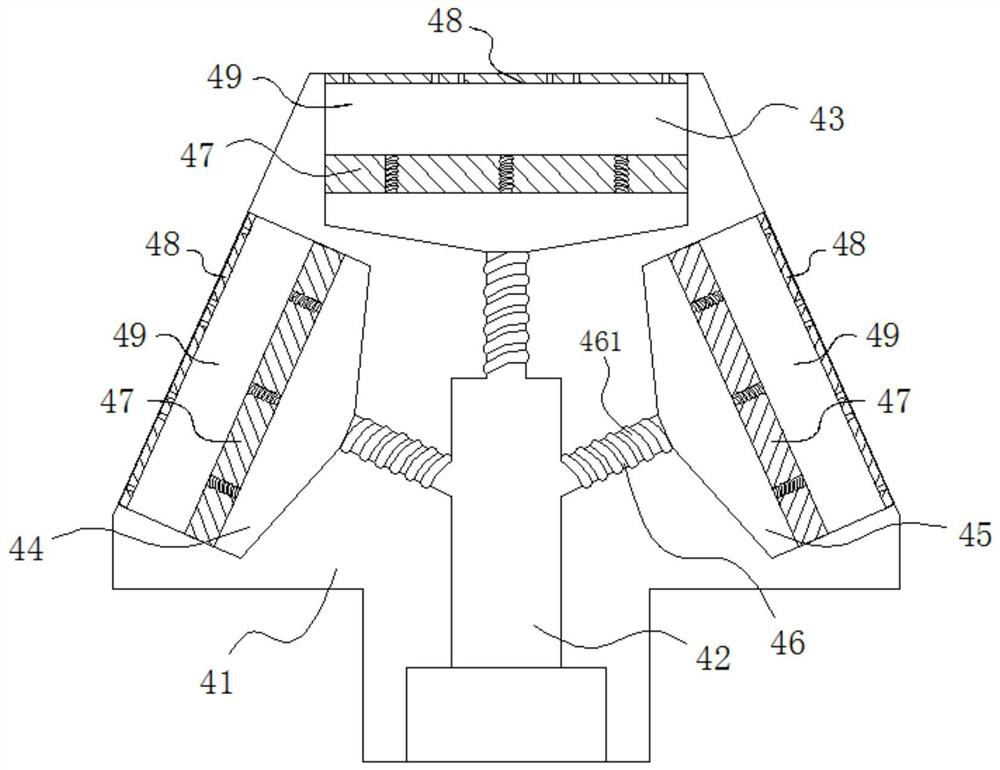

[0032] A process based on medical tablet coating processing, comprising the following steps: (1) manufacturing coating pulp: mixing talc, hydroxypropyl methylcellulose and nano-silicon dioxide in a mixer to obtain coating pulp , wherein the ratio of parts by weight between the talc, hydroxypropyl methylcellulose, nano-scale silicon dioxide is 2: 1.5: 1.3; be specifically to get 20kg of talc, 15kg of hydroxypropyl methylcellulose , the nanoscale silicon dioxide of 1.3kg is mixed and obtained; (2) preheating tablet: the tablet to be coated is placed in the coating equipment, such as Figure 1-7 As shown, the coating equipment includes an operation room 1, a spray gun 4, a jetting device 2, a feeding device 3 and a recovery device 5; The outer sleeve 21, the air-jet channel provided in the sleeve, the injection member 23 connected with the air-jet channel, and the blower 24, a heating element 25 is arranged between the blower 24 and the sleeve 21, and the heating element 25 passe...

Embodiment 2

[0039] A process based on medical tablet coating processing, comprising the following steps: (1) manufacturing coating pulp: mixing talc, hydroxypropyl methylcellulose and nano-silicon dioxide in a mixer to obtain coating pulp , wherein the ratio of parts by weight between the talc, hydroxypropyl methylcellulose, and nano-scale silicon dioxide is 4:2.5:1.6; specifically, taking 40kg of talc, 25kg of hydroxypropylmethylcellulose , the nanoscale silicon dioxide of 1.6kg is mixed to obtain; (2) preheating tablet: the tablet to be coated is placed in the coating equipment, such as Figure 1-7 As shown, the coating equipment includes an operation room 1, a spray gun 4, a jetting device 2, a feeding device 3 and a recovery device 5; The outer sleeve 21, the air-jet channel provided in the sleeve, the injection member 23 connected with the air-jet channel, and the blower 24, a heating element 25 is arranged between the blower 24 and the sleeve 21, and the heating element 25 passes th...

Embodiment 3

[0042] A process based on medical tablet coating processing, comprising the following steps: (1) manufacturing coating pulp: mixing talc, hydroxypropyl methylcellulose and nano-silicon dioxide in a mixer to obtain coating pulp , wherein the ratio of parts by weight between the talcum powder, hydroxypropyl methylcellulose, and nano-scale silicon dioxide is 3: 1.1: 0.96; specifically, taking 30kg of talc, 11kg of hydroxypropyl methylcellulose , the nanoscale silicon dioxide of 9.6kg is mixed and obtained; (2) preheating tablet: the tablet to be coated is placed in the coating equipment, such as Figure 1-7 As shown, the coating equipment includes an operation room 1, a spray gun 4, a jetting device 2, a feeding device 3 and a recovery device 5; The outer sleeve 21, the air-jet channel provided in the sleeve, the injection member 23 connected with the air-jet channel, and the blower 24, a heating element 25 is arranged between the blower 24 and the sleeve 21, and the heating elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com