Solid electrolyte as well as preparation method and application thereof

A solid electrolyte and electrolyte technology, applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., can solve the problems of complex preparation methods and difficult industrialization, achieve good flexibility, inhibit the production of lithium dendrites, The effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

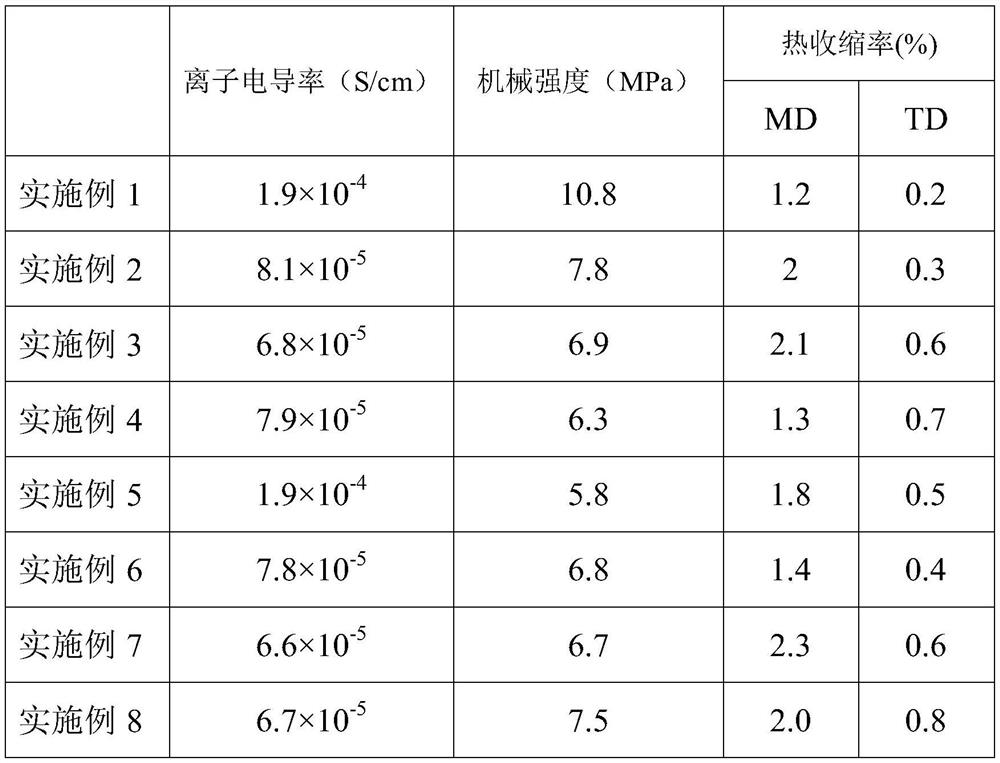

Embodiment 1

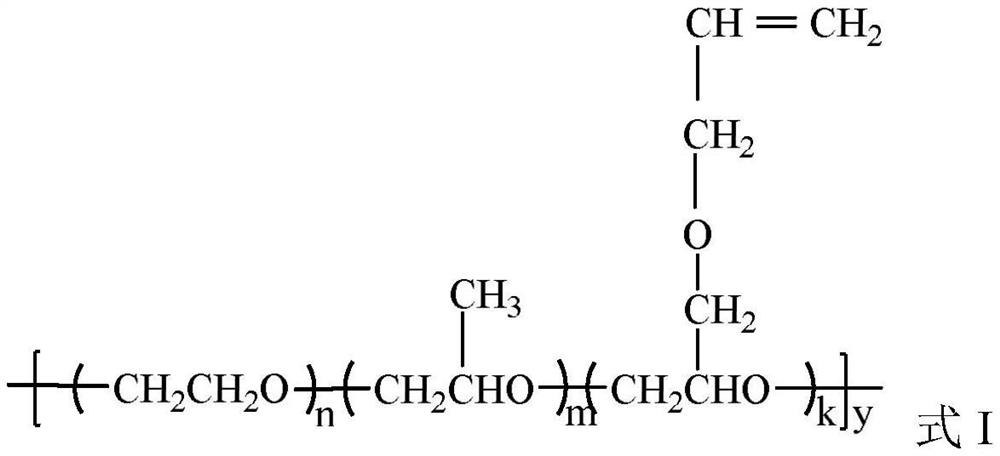

[0068] This embodiment provides a solid electrolyte, which includes the following components: PEO-PPO-1, Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 , LiPON, Li 7 La 3 Zr 2 o 12 and LiBOB.

[0069] The preparation method of the solid electrolyte is as follows:

[0070] (1) Add 0.1g of Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 , 0.1g of LiPON and 0.1g of Li 7 La 3 Zr 2 o 12 Add in 8g of acetone, stir for 1h, wherein the rotating speed is 500 rpm, then add 1g of LiBOB and 0.8g of polyethylene glycol (M n =2000), continue stirring for 1h to obtain a mixed solution;

[0071] (2) 2g of PEO-PPO-1 (structure shown in formula I, n:m:k=93:6:1, weight average molecular weight of 100,000) was added to the mixed solution, stirred at room temperature for 2h, Then add 0.02g of dibenzoyl peroxide, stir and mix, and the rotating speed is 720 revolutions / min to obtain an electrolyte slurry;

[0072] (3) The electrolyte slurry was double-coated on the NKK cellulose separator, heated at a constant t...

Embodiment 2

[0075] This embodiment provides a solid electrolyte, which includes the following components: PEO-PPO-2, Li 10GeP 2 S 12 and LiTFSI.

[0076] The preparation method of the solid electrolyte is as follows:

[0077] (1) Add 0.3gLi 10 GeP 2 S 12 Add in 8g of acetonitrile, stir for 0.5h, wherein the rotating speed is 200 rev / min, then add 1gLiTFSI and 0.8g polyethylene glycol (M n =2000), continue stirring for 0.5h to obtain a mixed solution;

[0078] (2) Add 2g of PEO-PPO-2 (structure shown in formula I, n:m:k=93:6:1, weight average molecular weight is 50,000) into the mixed solution, stir at room temperature for 1h, and then Add 0.01 g of azobisisobutyronitrile, stir and mix at a speed of 200 rpm to obtain an electrolyte slurry;

[0079] (3) Coating the electrolyte slurry on one side of the PTFE membrane, heating at a constant temperature of 50°C for 10h, and then baking in a vacuum oven at 50°C for 10h to obtain the solid electrolyte.

[0080] The steps (1) to (3) are ...

Embodiment 3

[0082] This embodiment provides a solid electrolyte, which includes the following components: PEO-PPO-3, Li 9.54 Si 1.74 P 1.44 S 11.7 Cl 0.3 and LiBOB.

[0083] The preparation method of the solid electrolyte is as follows:

[0084] (1) Add 0.3g Li 9.54 Si 1.74 P 1.44 S 11.7 Cl 0.3 Add it into 8g of tetrahydrofuran, stir for 2h, and the rotation speed is 600 rpm, then add 1g of LiBOB and 0.8g of ethylene carbonate in sequence, and continue to stir for 2h to obtain a mixed solution;

[0085] (2) Add PEO-PPO-3 (structure shown in formula I, n:m:k=93:6:1, weight average molecular weight is 200,000) into the mixed solution, stir at room temperature for 3h, and then Add 0.02g of dibenzoyl peroxide, stir and mix, and the rotating speed is 950 rpm to obtain electrolyte slurry;

[0086] (3) The electrolyte slurry was double-coated on the PP separator, heated at a constant temperature of 70° C. for 15 hours, and then baked in a vacuum oven at 70° C. for 15 hours to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com