Explosive material thermal stability grading method based on adiabatic acceleration calorimetry

A technology of accelerated calorimetry and thermal stability, applied in the field of explosives, can solve the problems of inability to quantify the value one by one accurately, evaluation of the danger degree of difficult materials, and lack of quantitative criteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

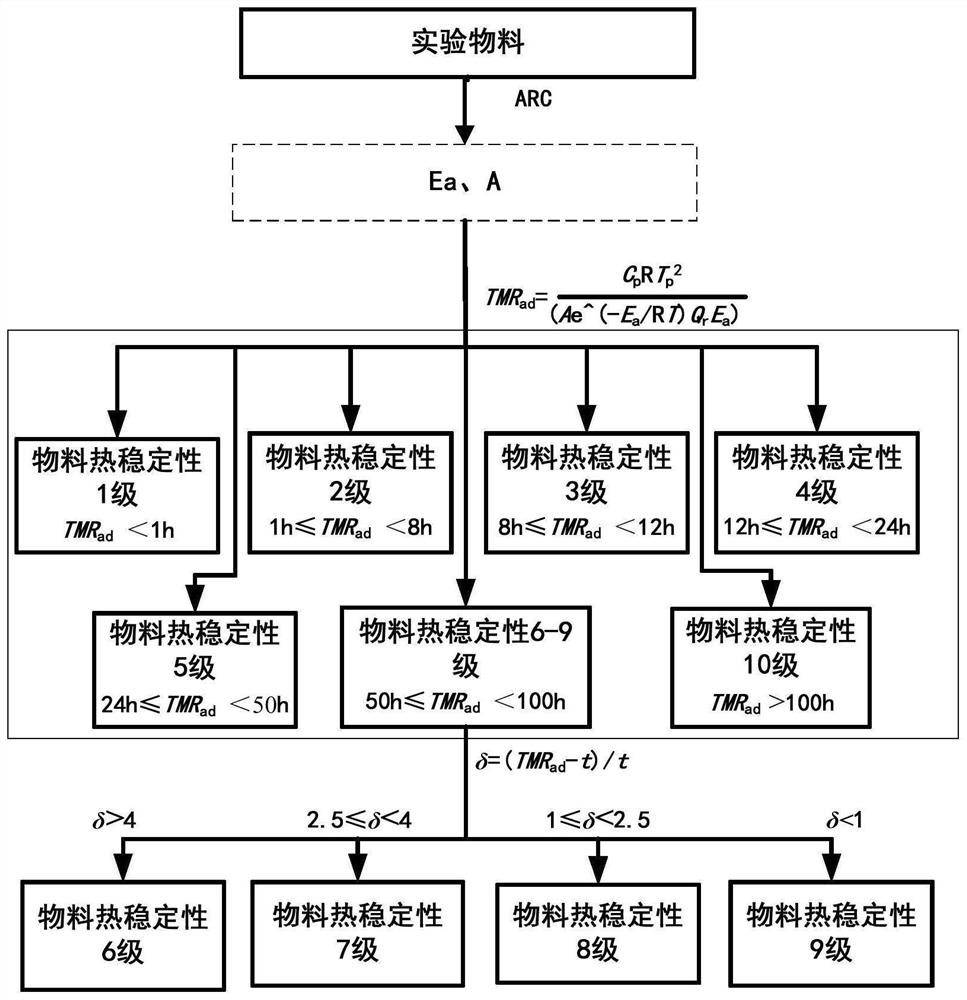

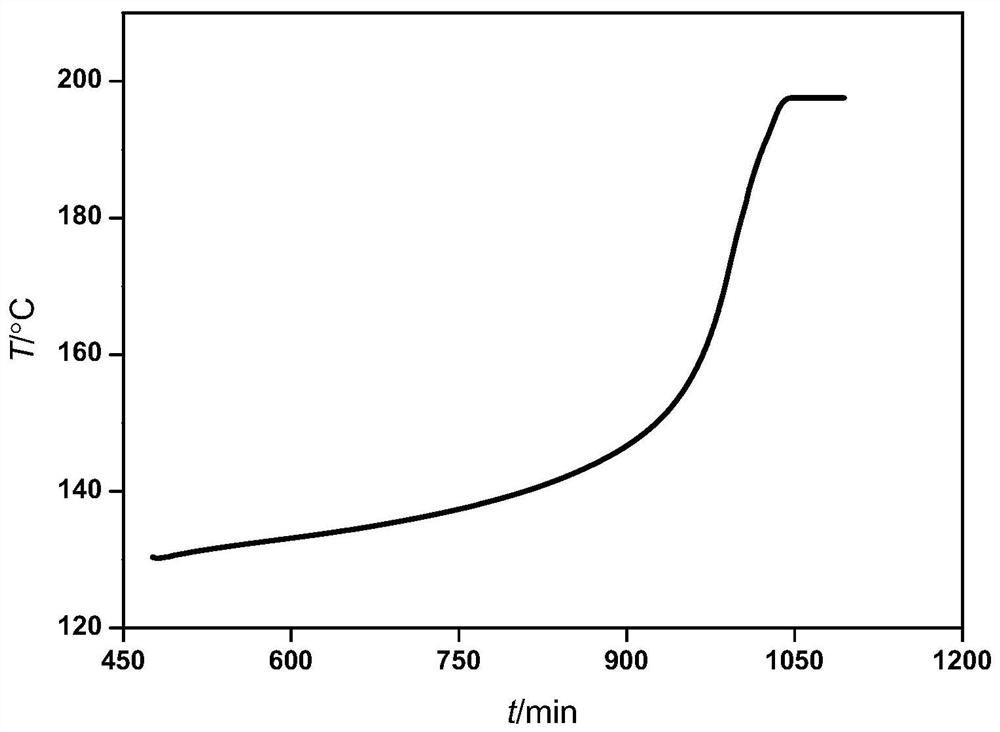

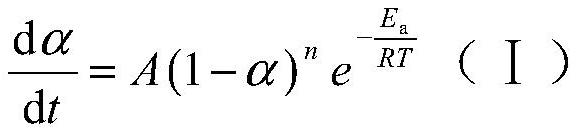

[0065] The present invention is a thermal stability test and classification evaluation method for materials in the manufacturing process of propellants and explosives. The typical propellant and explosives: GX modified double-base propellant manufacturing process materials are used as the research object, and the thermal decomposition of materials is tested by adiabatic accelerated calorimetry. Reaction, through equations (6) ~ (10), apply the linear least square method to obtain the kinetic parameter apparent activation energy E of material thermal decomposition reaction a and pre-exponential factor A, and then obtain the maximum reaction rate arrival time TMR under adiabatic conditions of different hazard levels ad The required process temperature T p , and process temperature T with different hazard levels p And the ratio operating time coefficient δ is the scale, and the actual process temperature T of the material in the process is compared and measured ps and the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com