Method for detecting wall thickness and wall thickness difference of bipyramid

A detection method, double cone technology, applied in the direction of measuring devices, instruments, computer control, etc., can solve the problems of poor uniformity of the manual push measurement process, human error of the measurement method, poor repeatability, etc., to achieve accurate and reliable measurement results and improve accuracy and efficiency, the effect of eliminating human influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

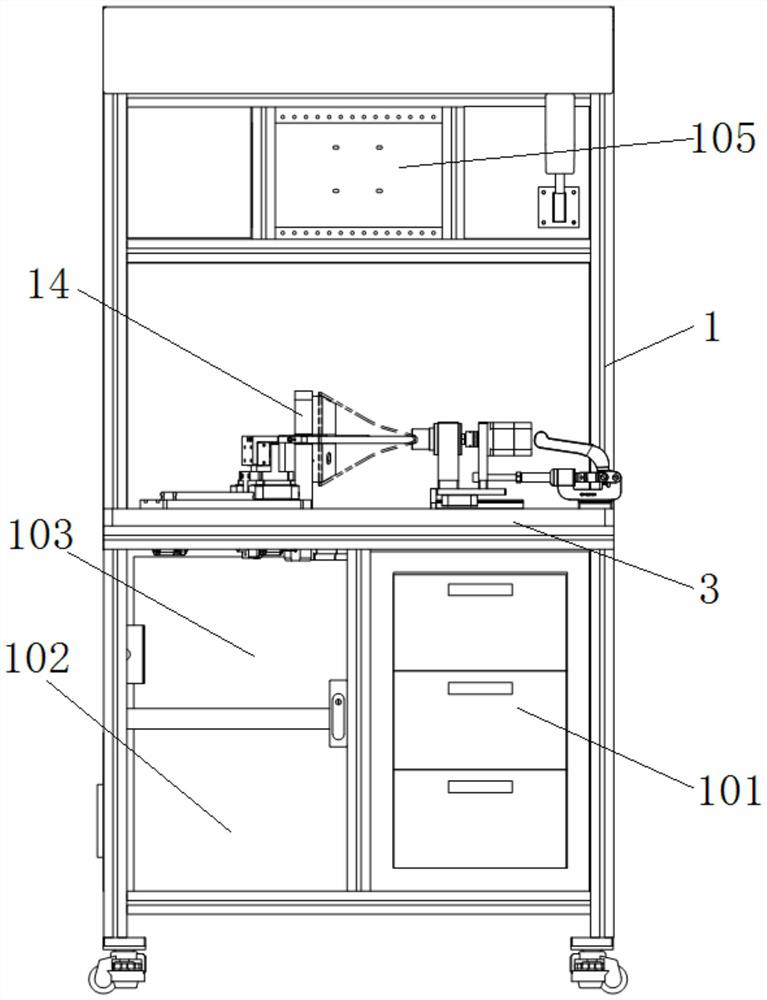

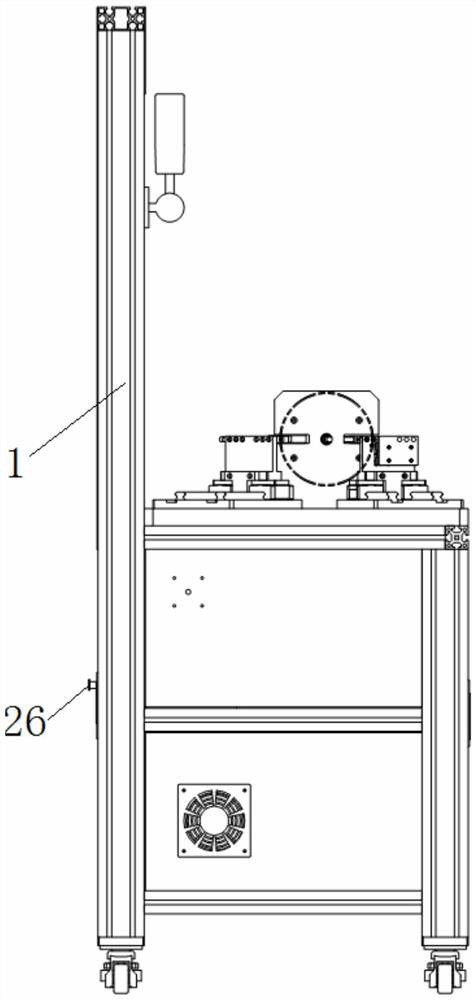

[0031] like Figure 2-Figure 3As shown, the detection device used in the present invention includes a frame 1, a workbench 3, a warning light 104, a computer 105, a large cone positioning seat, a small cone positioning seat, a large cone measuring assembly and a small cone measuring assembly. Described workbench 3, warning light 104, computer 105 are installed on the frame, and what computer 105 adopted is touch-screen computer, and what described warning light 104 adopted is three-color warning light, and warning light 104 is connected with computer 105. Described frame is also provided with electric cabinet 103, keyboard drawer 101 and printer 102, and electric cabinet 103 supplies power for computer, alarm lamp 8, printer 102, and printer 102 is connected with computer 9, is used for printing measurement result. The electrical cabinet 103 is provided with an air fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com