Offshore wind power large-diameter steel pipe pile

A technology of steel pipe piles and electric power stations, which is applied to sheet pile walls, protection devices, buildings, etc., can solve the problems of reducing the top impact of hydraulic hammers, damage to large ships and equipment, and achieve the effect of reducing construction costs and shortening construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing.

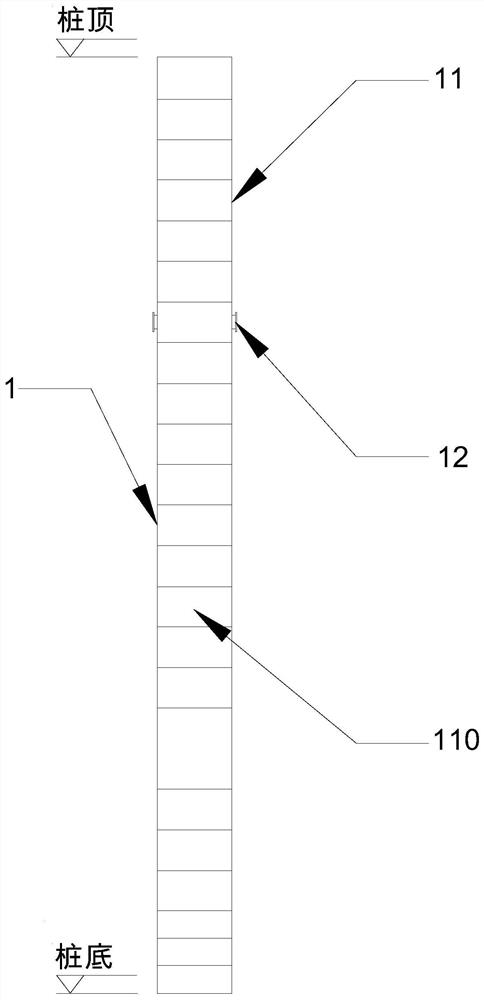

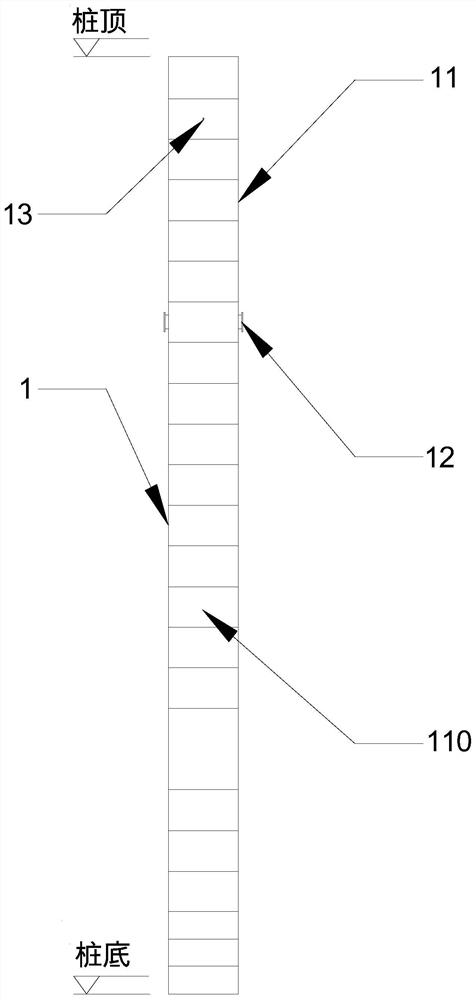

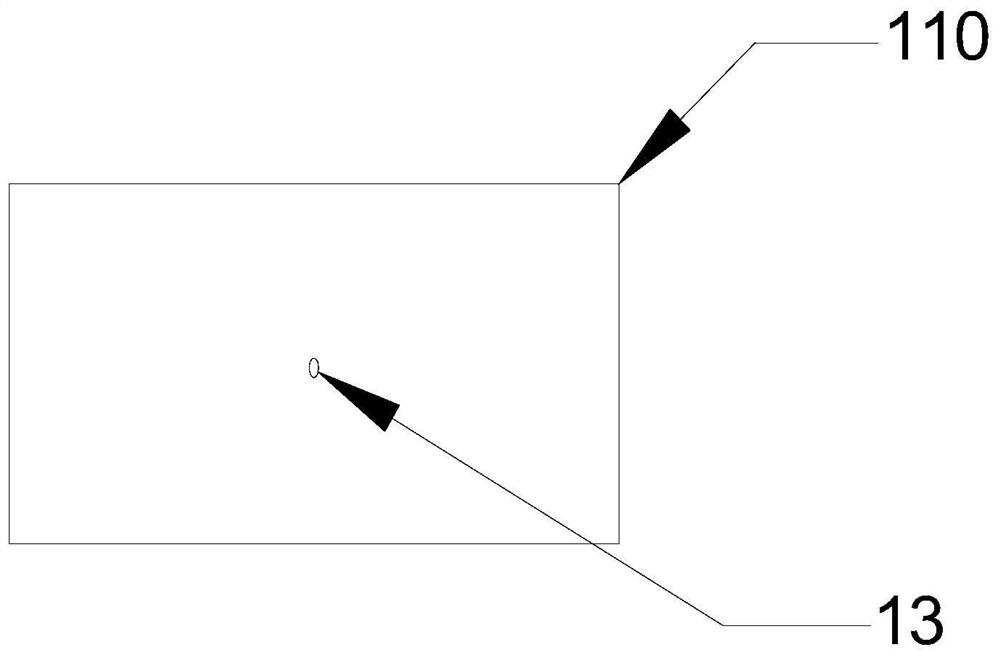

[0058] see figure 1 Referring to Fig. 5, the large-diameter steel pipe pile for offshore wind power of the present invention includes a steel pipe pile body 11 and lifting lugs 12; wherein, the steel pipe pile body 11 is formed by butt welding of several steel pipe pile joints 110;

[0059] The lifting lug 12 is fixed on the outer wall surface of the upper half of the steel pipe pile body 11;

[0060] Below the pile top of the steel pipe pile body 11, the middle part of the second steel pipe pile joint 110 is provided with several air holes 13 evenly distributed along the wall surface of the pile, and several air holes 13 are all connected with the steel pipe pile body 11. The attached components on the top are staggered; the number of vent holes 13 can be set according to actual needs, and the number of vent holes 13 in this embodiment is two.

[0061] Each ventilation hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com