Spunlace disordered fuzzy printed cloth and preparation method thereof

A printed cloth and spunlace technology, which is applied in the field of non-woven materials, can solve the problems of reduced visual contrast, clear vision and dizziness of printed spunlace wiping cloth, and achieve the effects of avoiding dazzling, various colors and high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

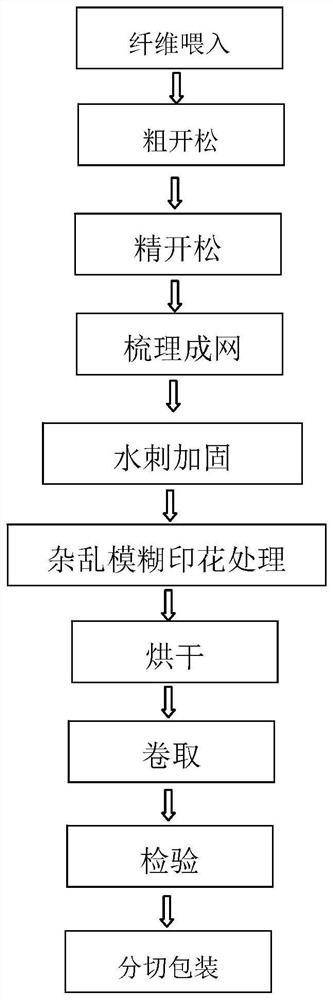

[0025] Such as figure 1 As shown, the present invention provides a kind of preparation method of spunlace messy fuzzy calico, comprises the following steps:

[0026] Fiber feeding→coarse opening→fine opening→carding→spunlace reinforcement→messy and fuzzy printing treatment→drying→coiling→inspection.

[0027] The messy and fuzzy printing process specifically includes the following steps: spunlace wet cloth→light-colored foam dipping→diamond pattern roller printing→conveyor chain support→drying.

[0028] Wherein the liquid-carrying rate of the spunlace wet cloth is 90-170%; the liquid-carrying rate of the light-colored foam after dipping is 150-260%; and the liquid-carrying rate of the patterned roller printing is 180-320%.

[0029] Wherein the drying temperature is 120-170°C, and the drying time is 20s-2 minutes.

[0030] The finishing liquid impregnated with light-colored foam is composed of the following components by weight percentage: polyacrylate 1wt%-15wt%; pigment 0.03...

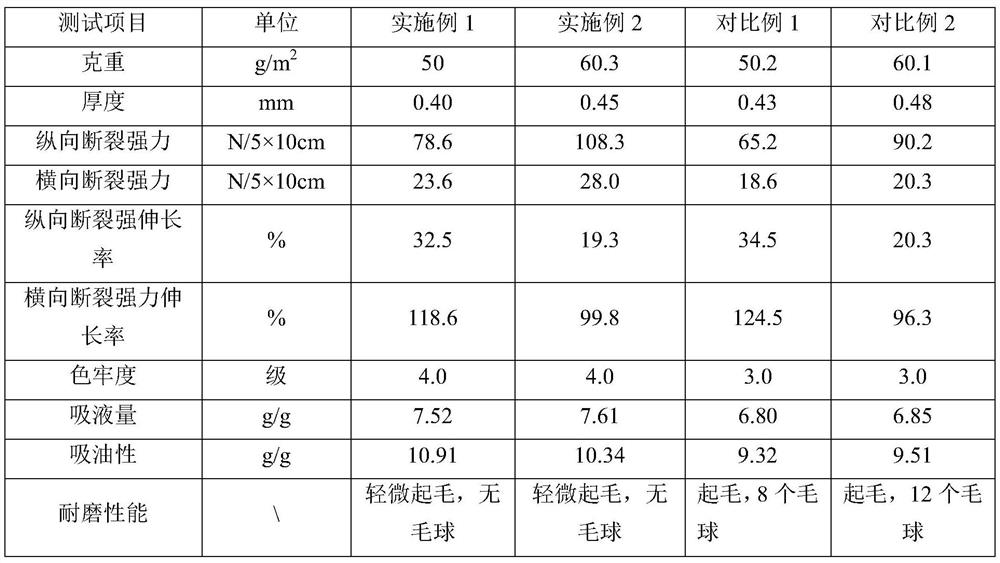

Embodiment 1

[0034] Embodiment 1 star pattern messy fuzzy printing

[0035] Such as figure 1 As shown, the present embodiment provides a method for preparing spunlace messy fuzzy calico (star pattern), comprising the following steps:

[0036] 1) Prepare the raw material, polyester fiber, the specification is 1.4D×38mm.

[0037] 2) Feed large pieces of polyester fiber into the open feeder for opening, and become small fiber clumps, which are transported to the carding machine for further opening through the air flow, and the large cylinder and work roller of the carding machine comb the fiber bundles into a smooth Fiber web, and then through the doffer to form a better fiber web, the weight of the fiber web is 42g / ㎡.

[0038] 3) The fiber web is pre-wetted (0-10bar hydraulic pressure spunlace), and the front and back drums are spunlace, so that the fibers in the fiber web are entangled with each other to form a spunlace non-woven fabric. The spunlace head is spunlace The pressures are 20...

Embodiment 2

[0041] Example 2 Diamond Pattern Messy and Fuzzy Printing

[0042] Such as figure 1 As shown, the present embodiment provides a method for preparing spunlace messy and fuzzy calico (diamond pattern), comprising the following steps:

[0043] 1) Prepare raw materials, polypropylene fiber, the specification is 1.4D×38mm; viscose fiber, the specification is 1.4D×38mm.

[0044]2) Feed large pieces of fiber raw materials into the open feeder for opening, and become small fiber clumps, which are transported to the carding machine by air flow for further opening. The fiber web is then passed through a doffer to form a better fiber web, and the weight of the fiber web is 55g / ㎡.

[0045] 3) The fiber web is pre-wetted (0-10bar hydraulic pressure spunlace), and the front and back drums are spunlace, so that the fibers in the fiber web are entangled with each other to form a spunlace non-woven fabric. The spunlace head is spunlace The pressures are 20 bar, 30 bar, 45 bar, 60 bar, 80 ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com