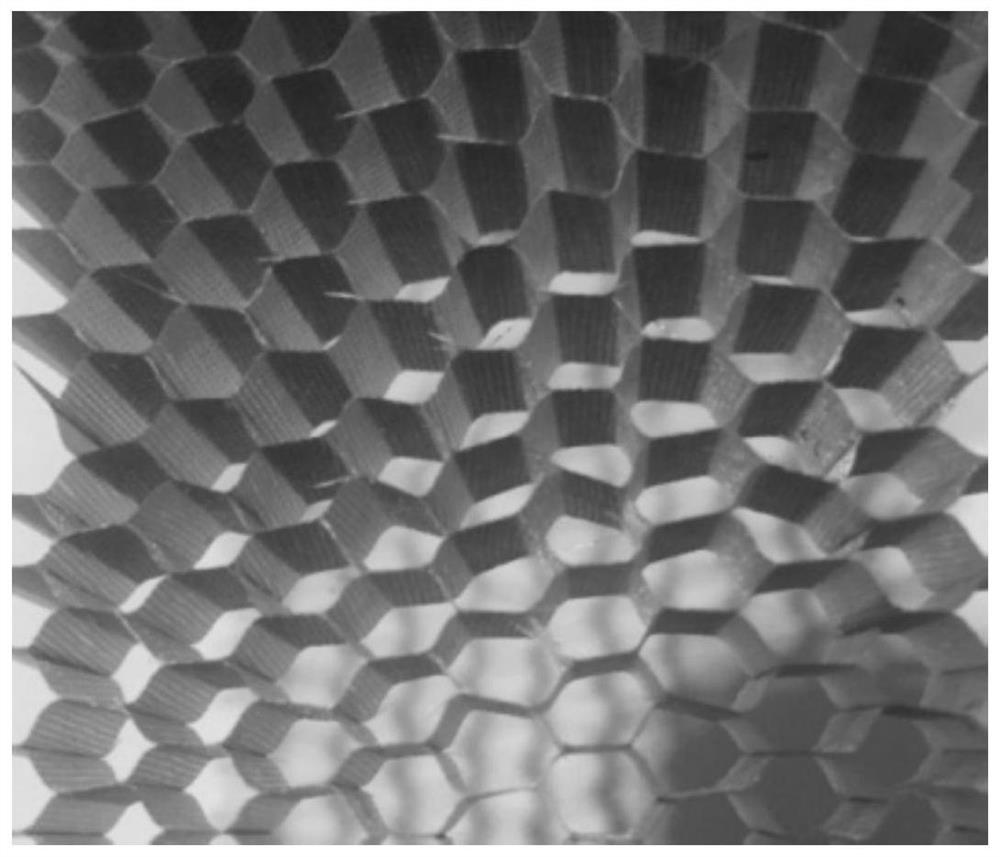

High-temperature-resistant thin-wall glass cloth honeycomb core strip adhesive as well as preparation method and application thereof

A technology of glass cloth and high temperature resistance, which is applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., and can solve the problem of poor maturity and stability of high temperature resistant paper and increase core strip adhesive Viscosity, core strip viscosity increase and other problems, to achieve the effect of improving penetration, increasing the amount of addition, and increasing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

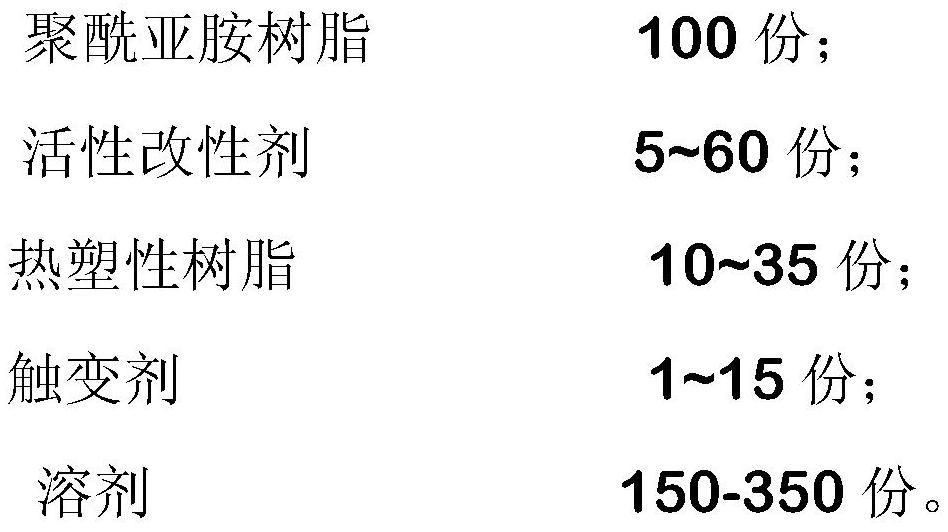

[0040] In a preferred embodiment of the present invention, the solvent includes any one of acetone, butanone, cyclohexane, tetrahydrofuran, and diethylene glycol dimethyl ether, preferably acetone, which has a low boiling point, low toxicity, and low cost. According to the present invention, there is provided a method for preparing high temperature resistant ultra-thin glass cloth honeycomb core strip glue, comprising the following steps:

[0041] (1) Add 1 / 4-1 / 3 part of micron-scale toughening agent to the reactive agent, dissolve the toughening agent in the reactive agent in the range of 100-150°C, cool down to below 80°C, and remove the remaining The micron-scale toughening agent and nano-scale thixotropic agent are added to the reactive agent, and high-speed stirring is dispersed to obtain component A

[0042] (2) Under the condition of stirring at room temperature, add the polyimide resin and component A into the solvent to dissolve and disperse to obtain a thin-walled glas...

Embodiment 1

[0045] ingredient name content Remark thermosetting polyimide 100g Alkynyl capping Alkynyl benzoxazine resin 40g thermoplastic polyimide 25g Particle size 18μm Nano silica 10g acetone 300g

[0046] 1. Preparation of component A: Weigh 7g of thermoplastic polyimide (P84) and add it to 40g of alkynyl benzoxazine, heat to 120°C and keep it warm until the thermoplastic polyimide is dissolved and transparent, cool down to below 80°C, add 18g thermoplastic polyimide and 10g nano-silica, high-speed dispersion is enough.

[0047] 2. Preparation of high-temperature-resistant core strip glue: under the condition of high-speed stirring at room temperature, add 75g of component A and 100g of thermosetting polyimide resin into 300g of acetone, dissolve, mix and disperse evenly.

[0048] The tensile shear strength (GB / T7124-2008) of the high temperature-resistant core strip at room temperature is 25.3MPa, and the tensile shear streng...

Embodiment 2

[0052] ingredient name content Remark thermosetting polyimide 100g Norbornene-capped Alkynyl benzoxazine resin 60g polyamideimide 20g Particle size 12um Nano silica 5g butanone 210g

[0053] 1. Preparation of component A: Weigh 5g of polyamideimide and add it to 60g of alkynyl benzoxazine, heat to 120°C and keep it warm until the polyamideimide is dissolved and transparent, cool down to below 80°C, and add 15g of polyamide Imide and 5g nano-silica can be dispersed evenly at high speed.

[0054] 2. Preparation of high-temperature-resistant core strip glue: under the condition of high-speed stirring at room temperature, add 85g of component A and 100g of thermosetting polyimide resin into 210g of acetone, dissolve, mix and disperse evenly.

[0055] The tensile shear strength (GB / T7124-2008) of high temperature resistant core strip glue at room temperature is 27.3MPa, and the tensile shear strength at 300°C reaches 12.8MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com