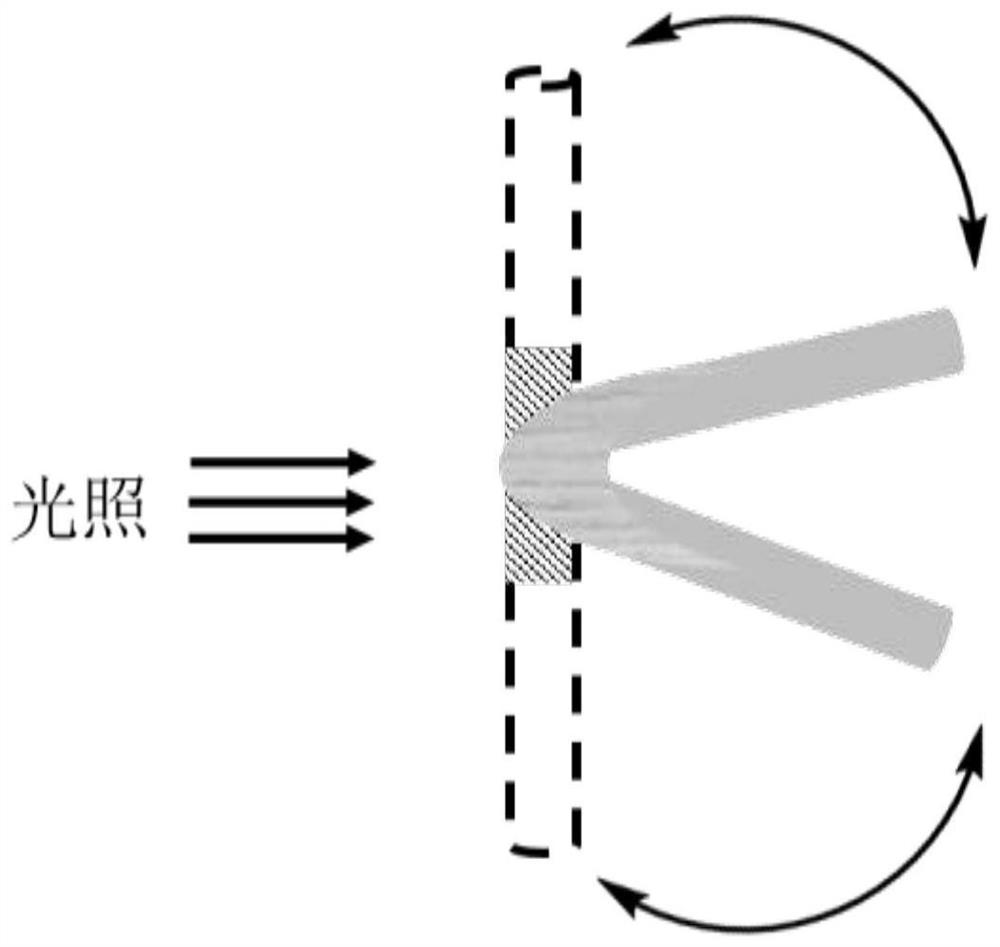

A light-driven flexible film based on salicylaldehyde Schiff base, its preparation method and application

An aldehyde Schiff base and light-driven technology, applied in the field of organic chemistry, can solve problems such as high cost, complex synthesis process, and lack of liquid crystal properties, and achieve the effect of simple preparation, simple and cheap preparation method, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

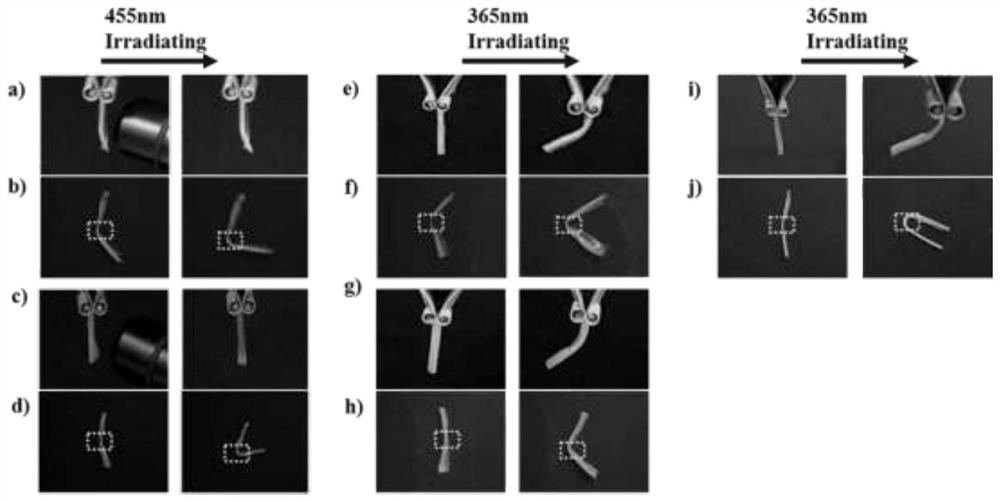

Method used

Image

Examples

Embodiment 1

[0038] Preparation of salicylaldehyde Schiff base molecule: Under nitrogen protection, dissolve compounds 1, 2 and anhydrous magnesium sulfate in an equivalent ratio of 1:1:2 in absolute ethanol, stir and react at room temperature for 2 hours, then remove by suction filtration Anhydrous magnesium sulfate, and washed with an appropriate amount of absolute ethanol until the anhydrous magnesium sulfate is white, the product is recrystallized with petroleum ether / n-hexane, and vacuum-dried to obtain the product (I), wherein compound 1 is 2 for Product (I) is

[0039] (I)

Embodiment 2

[0042] Step 1: Prepare a mixed solution based on salicylaldehyde Schiff base molecules and flexible polymers

[0043] Salicylaldehyde Schiff base molecule And flexible polymer polyethylene phthalate (PET), the average molecular weight of its polymer PET is 2~3×10 4 , The ratio of weight average to number average molecular weight is 1.5-1.8. The two were weighed at a mass ratio of 1:15, and a mixed solution was prepared according to the ratio of the mixture and the toluene solution at a ratio of 60 mg / mL, and stirred and dissolved at 45°C.

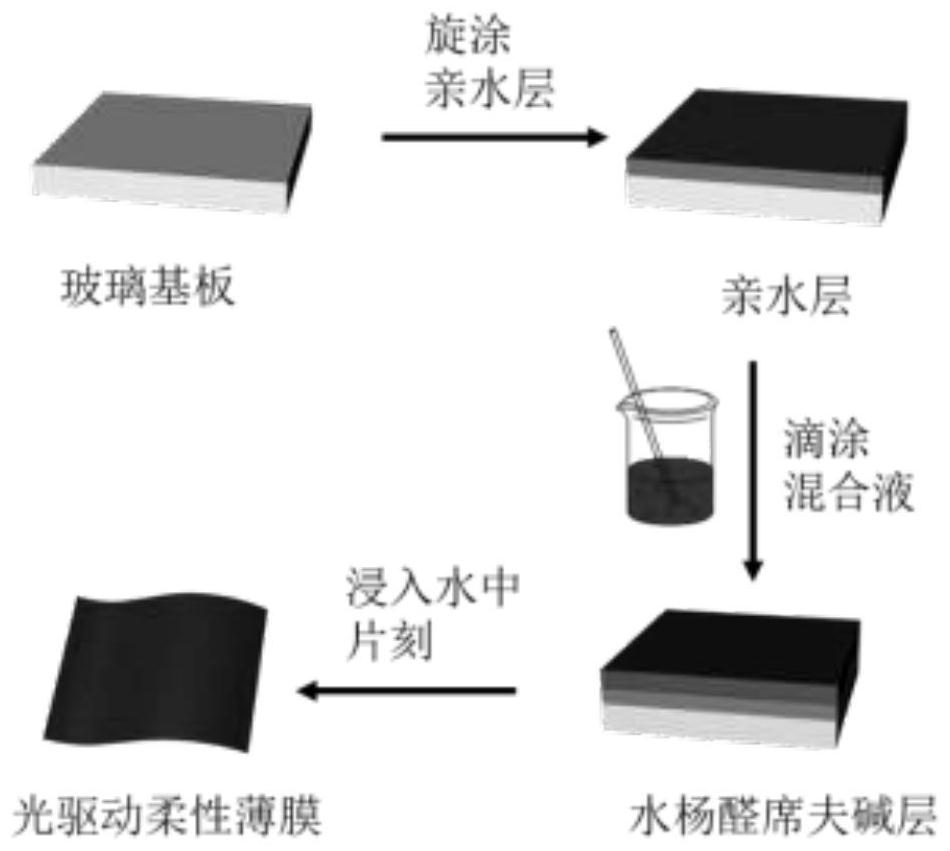

[0044] Step 2: Preparation of Optically Actuated Flexible Film

[0045] The glass substrate is ultrasonically cleaned with dichloromethane and toluene solution to ensure that it is clean and ready for use. Spin-coat PEDOT:PSS glass substrate with a thickness of about 100-300nm on the surface of the glass substrate as a sacrificial layer. After the spin coating is completed, the surface layer has PEDOT:PSS The glass substrate was anneale...

Embodiment 3

[0051] Step 1: Prepare a mixed solution based on salicylaldehyde Schiff base molecules and flexible polymers

[0052] Using the Salicylaldehyde Schiff Base Molecule Weigh it with polymer PET at a mass ratio of 1:8, prepare an initial solution according to the mixture and toluene solution at a ratio of 65mg / mL, stir and dissolve at 50°C, and the rest is the same as step 1 of Example 1.

[0053] Step 2: Preparation of Optically Actuated Flexible Film

[0054] The glass substrate is ultrasonically cleaned with dichloromethane and toluene solution to ensure that it is clean and ready for use. Spin-coat 10mg / mL sodium carboxymethylcellulose with a thickness of about 100-300nm on the glass substrate as a sacrificial layer on the glass substrate. Spin-coating is completed Finally, the glass substrate with sodium carboxymethyl cellulose on the surface is placed on a hot stage at 150° C. for annealing treatment. Then place the surface-treated glass substrate on a hot stage at 45°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com