A preparation method of nano-sic that can be used as negative electrode material of lithium ion battery and lithium ion battery prepared by using the negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied to the preparation of nano-SiC, lithium-ion batteries. field, can solve the problems of lack of purity, high cost, complex synthesis route, etc., and achieve the effects of stable charge and discharge performance, uniform element distribution, and high volume capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

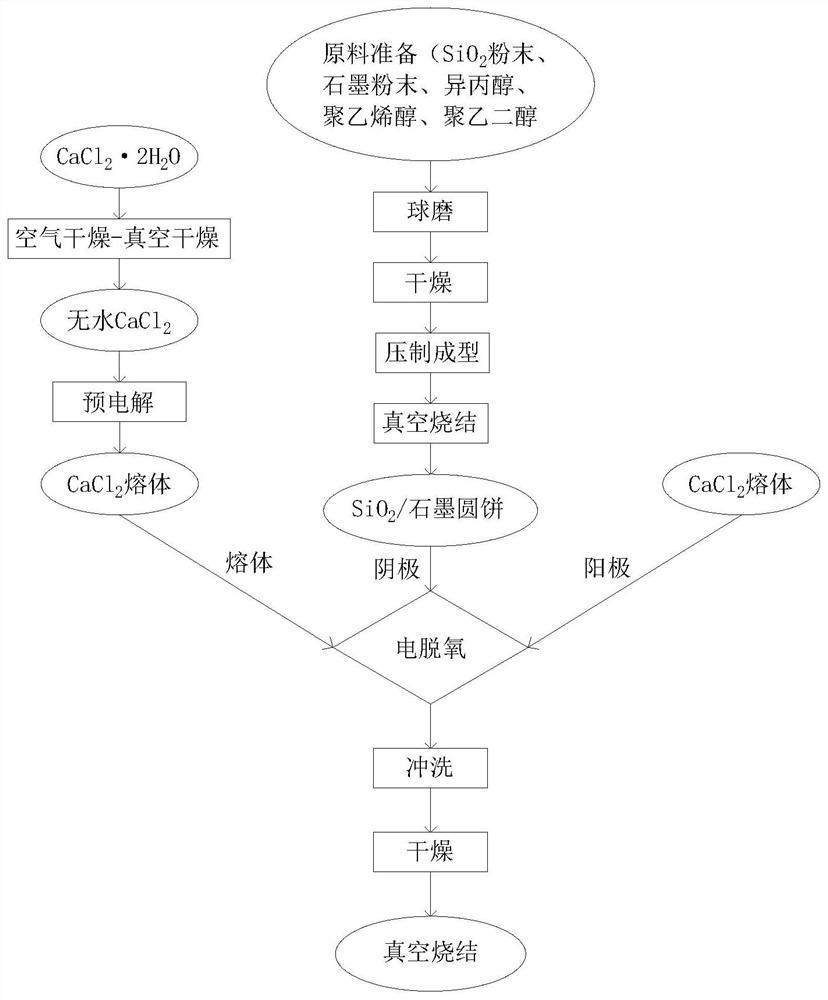

Method used

Image

Examples

Embodiment 1

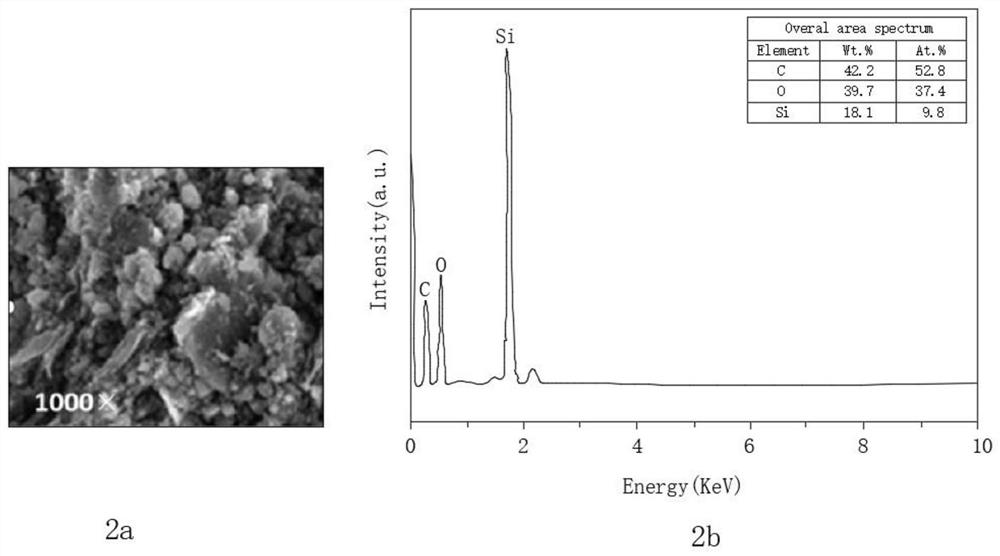

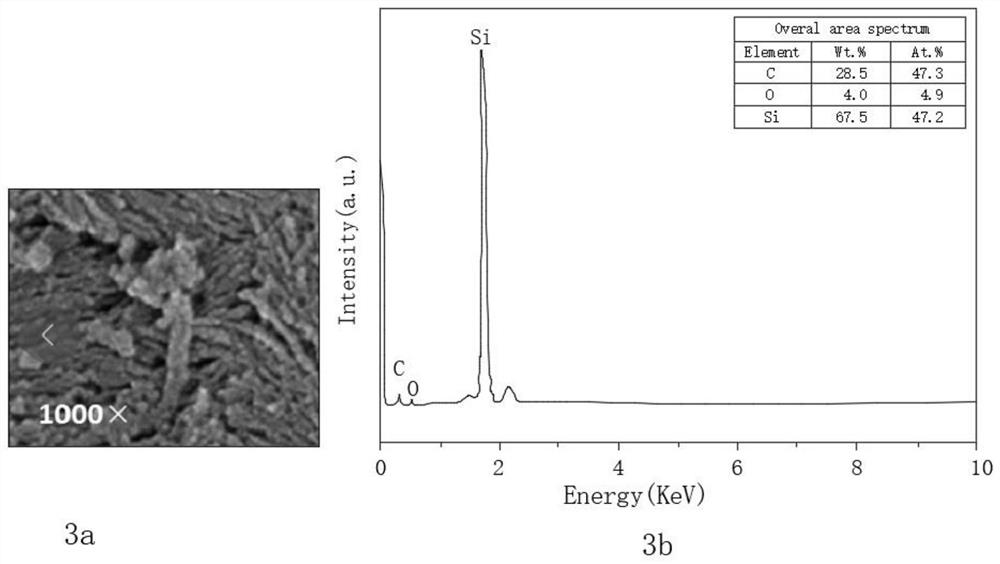

[0047] First weigh 98 parts of isopropanol, 1 part of polyvinyl alcohol, and 0.5 parts of polyethylene glycol, put them into a ball mill tank, stir them properly with a glass rod, and then weigh 10 parts of SiO 2 The powder and 15 parts of graphite powder should be properly stirred with a glass rod and then ball milled. After being fully dispersed, take it out and dry it in a drying oven at 100°C. Press it into a 0.4g round cake with a diameter of 12mm under a pressure of 5MPa. , transferred to a high-temperature oven for sintering at 1200°C, the sintering time is 2.5h, and the sintering atmosphere is Ar+3vt%H 2 , In addition, take 550g CaCl 2 • 2H 2 O was dried in air at 180°C for 48h and then vacuum-dried at the same temperature for 24h, or air-dried at 260°C for 12h and then vacuum-dried at the same temperature for 6h to obtain CaCl 2 , weigh the CaCl prepared in the previous step 2 About 400g is placed in an alumina crucible, and then placed in a vertical high-temperatu...

Embodiment 2

[0050] First weigh 99 parts of isopropanol, 1.2 parts of polyvinyl alcohol, and 1 part of polyethylene glycol, put them into a ball mill tank and stir them properly with a glass rod, then weigh 5 parts of SiO 2 The powder and 8 parts of graphite powder are properly stirred with a glass rod and then ball milled. After being fully dispersed and uniform, they are taken out and dried in an oven at 110°C. Under a pressure of 8MPa, they are pressed into a 1g round cake with a diameter of 18mm. Transfer to a high temperature oven for sintering at 1250°C, the sintering time is 3h, and the sintering atmosphere is Ar+4vt%H 2 , In addition, take 550g CaCl 2 2H 2 O was dried in air at 180°C for 48h and then vacuum-dried at the same temperature for 24h, or air-dried at 280°C for 12h and then vacuum-dried at the same temperature for 6h to obtain CaCl 2 , weigh the CaCl prepared in the previous step 2 About 400g is placed in an alumina crucible, and then placed in a vertical high-tempera...

Embodiment 3

[0053] First weigh 100 parts of isopropanol, 1.5 parts of polyvinyl alcohol, and 1 part of polyethylene glycol, put them into a ball mill tank and stir them properly with a glass rod, and then weigh 10 parts of SiO 2 The powder and 15 parts of graphite powder are properly stirred with a glass rod and then ball milled. After being fully dispersed, take it out and put it in an oven for drying at 120°C. Press it into a 2g round cake with a diameter of 25mm under a pressure of 10MPa. Transfer to a high-temperature oven for sintering at 1300°C, the sintering time is 2.5h-3.5h, and the sintering atmosphere is Ar+6vt%H 2 , In addition, take 550g CaCl 2 2H2O was dried in air at 200°C for 48h and then vacuum-dried at the same temperature for 24h, or air-dried at 300°C for 12h and then vacuum-dried at the same temperature for 6h to obtain CaCl 2 , weigh the CaCl prepared in the previous step 2 About 400g is placed in an alumina crucible, and then placed in a vertical high-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com