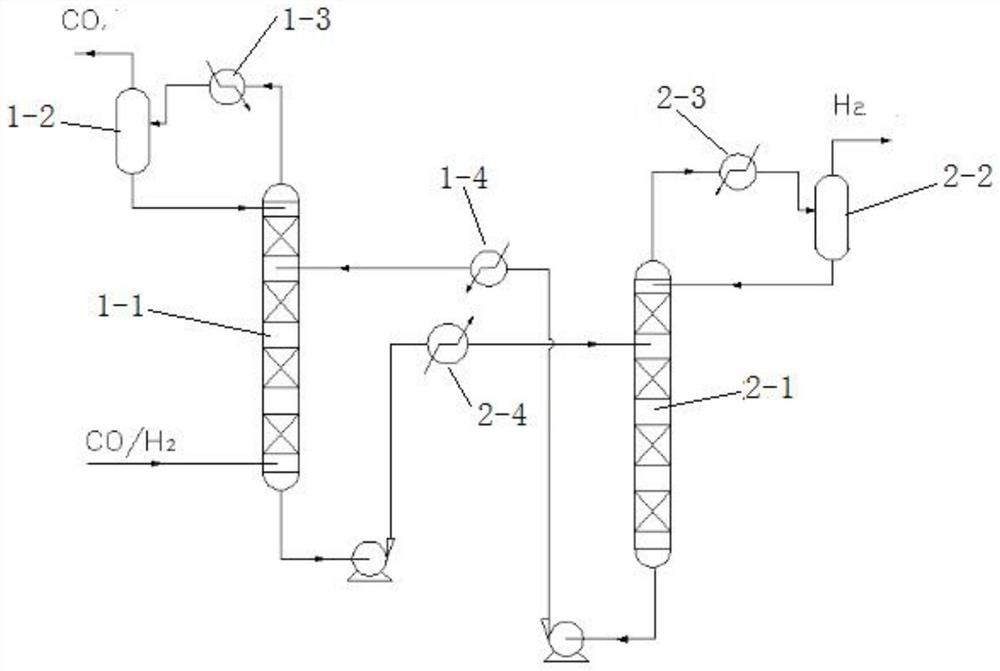

Carbon monoxide raw material gas dehydrogenation separation and purification process

A carbon monoxide and raw gas technology, applied in the directions of carbon monoxide, hydrogen separation, using liquid contact hydrogen separation, etc., can solve the problems of carbon monoxide reaction reactor, flying temperature, etc., and achieve the effect of small circulation, simple operation and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Hydrogen absorption, preheating cyclohexane to 120°C and hydrogen absorption reaction with carbon monoxide raw material gas with a hydrogen volume ratio of 0.6% under the action of a ruthenium carbon catalyst, the reaction temperature is 120°C, and the volume ratio of carbon monoxide raw material gas to cyclohexane is 2000:1, the reaction space velocity is 3000h -1 , react to obtain hydrogen absorbing liquid and primary carbon monoxide treatment gas, and the primary carbon monoxide treatment gas is cooled to 30-50°C for gas-liquid separation, and the separated gas is carbon monoxide treatment gas.

[0048] Dehydrogenation, preheat the hydrogen absorbing liquid obtained in the hydrogen absorbing step to 160°C, and then carry out a dehydrogenation reaction under the action of a ruthenium carbon catalyst. Gas-liquid separation is carried out after ~50°C, and the separated gas is purified hydrogen.

[0049] The purification and separation process of Examples 2 to 6 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com