Highlight gold stamping foil

A bronzing foil and high-brightness technology, applied in the field of bronzing foil, can solve the problems of low brightness and poor light transmission of metal highlights, and achieve the effects of good peelability, smooth release surface, and enhanced peeling smoothness.

Inactive Publication Date: 2020-12-04

浙江驰怀烫印科技股份有限公司

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a high-brightness bronzing foil to solve the problem of poor light transmission of each coating of the bronzing film and low brightness of metal highlights in the above-mentioned background technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0038]

[0039]

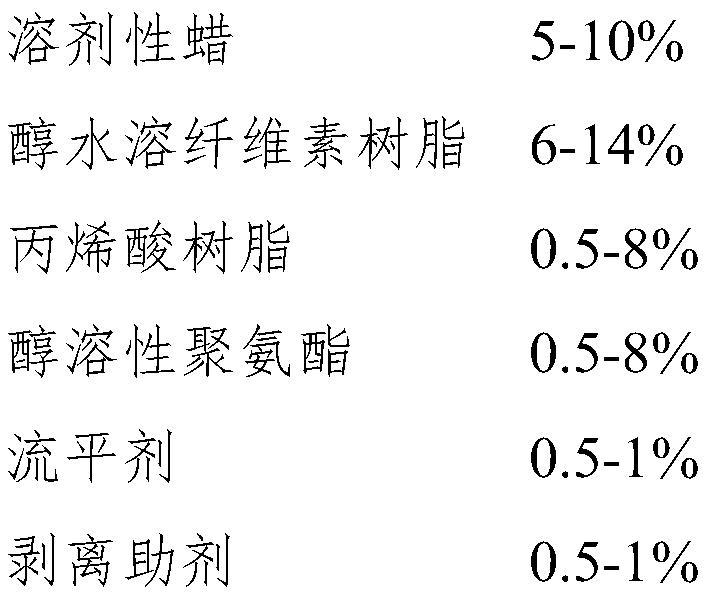

[0040]Add the alcohol water-soluble cellulose to the alcohol solvent, stir to fully dissolve it; add acrylic resin, alcohol-soluble polyurethane, continue to stir to fully dissolve; add leveling agent, stir evenly, add distilled water, polyethylene glycol ether and The fatty acid glyceride is filtered to obtain a delamination paint.

Embodiment 2

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

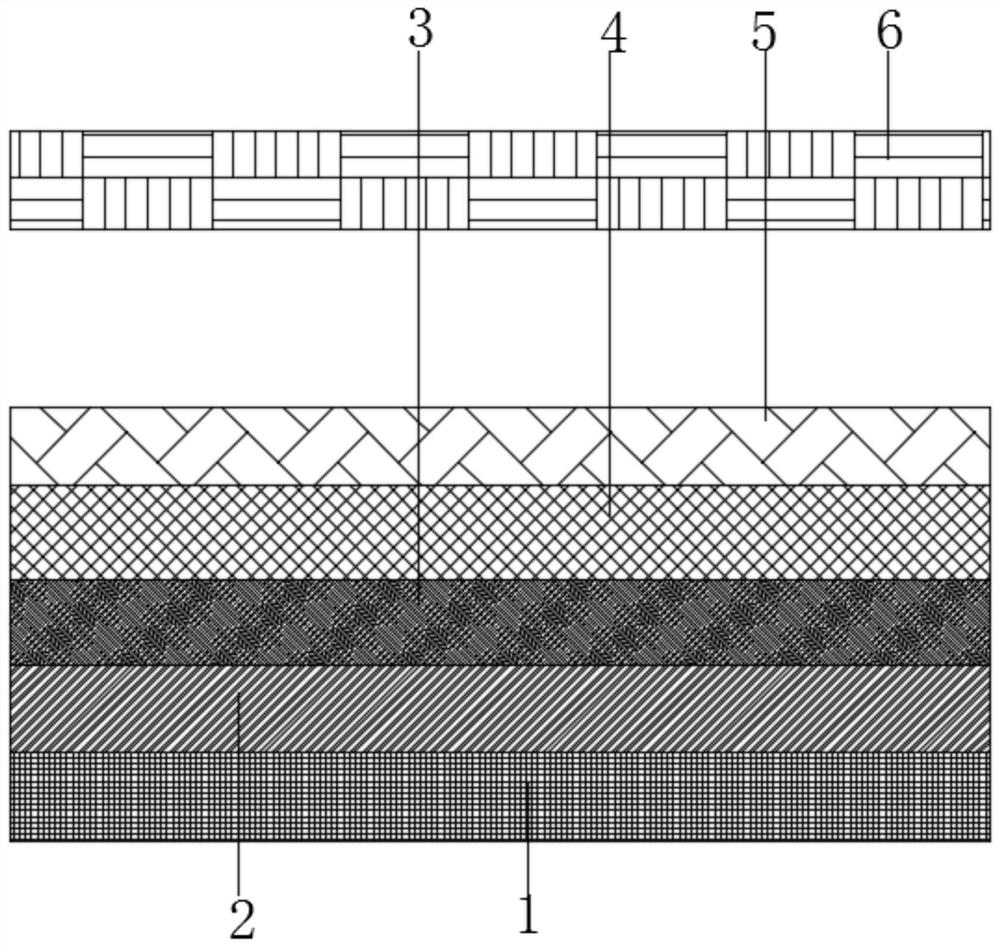

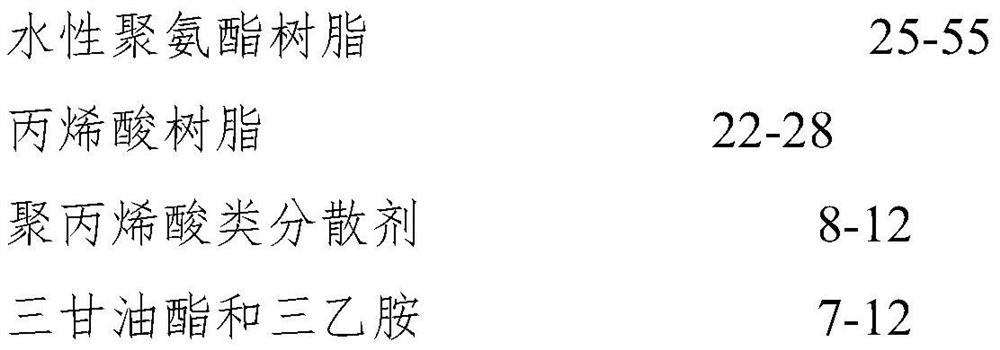

The invention discloses a highlight gold stamping foil in the technical field of gold stamping foils. The highlight gold stamping foil comprises a hot melt adhesive layer, an aluminized coating, a protective layer, a release layer and a base layer, wherein the base layer is a biaxially oriented polyester film; the release layer is formed by coating release paint; the release layer is formed by mixing solvent wax and acrylic resin; the protective layer is formed by coating polyurethane resin paint; and the hot melt adhesive layer is made of copolymer resin. According to the highlight gold stamping foil, the release layer is made of a mixture of the solvent wax and the acrylic resin, so that the stripping performance is good, the release surface is smooth, and the surface gloss of a printedor aluminized coating after heat transfer printing is not affected; the protective layer is made of waterborne polyurethane resin, so that the metal luster is not blocked while the aluminized coatingis protected, and the highlight characteristic is provided; and the hot melt adhesive layer adopts a copolymer resin hot melt adhesive to improve the effect of rotary viscosity and improve the interlayer adhesive force between the aluminized coating and a stamped layer, so that the clearness of hot stamping handwriting is improved.

Description

Technical field[0001]The invention relates to the technical field of hot stamping foil, in particular to a bright hot stamping foil.Background technique[0002]Hot stamping film, also known as anodized aluminum (the name of anodized aluminum is more used in the printing industry), is a hot stamping material made by adding a layer of metal foil to the film base by coating and vacuum evaporation. The film is widely used in the field of clothing and shoe materials using cloth, leather, etc. as raw materials, and various patterns are printed on the clothing and leather to increase the appearance of the clothing. The bronzing film is generally made by coating the release layer and the color layer on the film, and then coating the glue layer by vacuum aluminum plating, and finally rewinding the finished product, generally 4 to 5 layers. The existing bronzing film has a transparent coating. The light is not good, and the metal highlight has low brightness.[0003]Based on this, the present inv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B44C1/14B44C1/17C09D5/20C09D101/02C09D191/06C09D7/63C09D7/65C09D4/02C09D4/06C09J125/14C09J133/14

CPCB44C1/14B44C1/1729C08L2201/08C08L2201/10C08L2205/035C09D4/06C09D5/20C09D101/02C09J133/066C09D7/63C09D7/65C08L91/06C08L33/00C08L75/04C08L71/02C08K5/103

Inventor 邓德纯

Owner 浙江驰怀烫印科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com