A kind of selenium, nitrogen co-doped biochar catalytic material and its preparation method and application

A catalytic material, co-doping technology, applied in the field of chemical materials, to achieve the effect of improving cost-effectiveness, reducing loading, and high electron transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

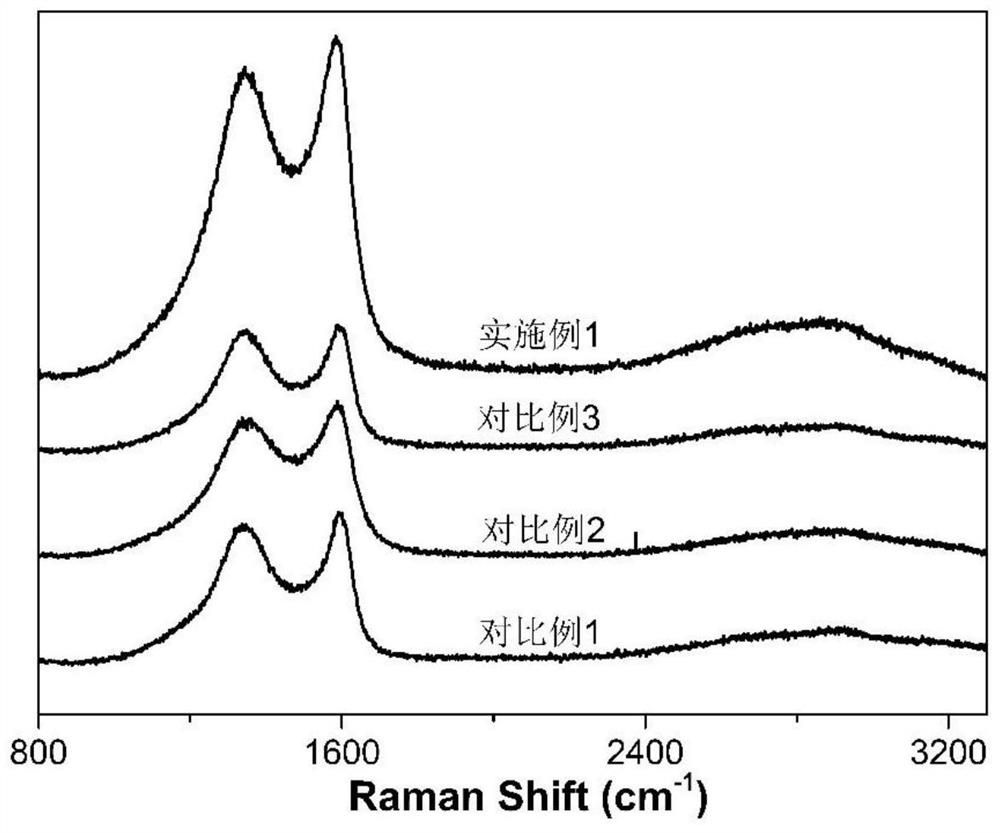

Embodiment 1

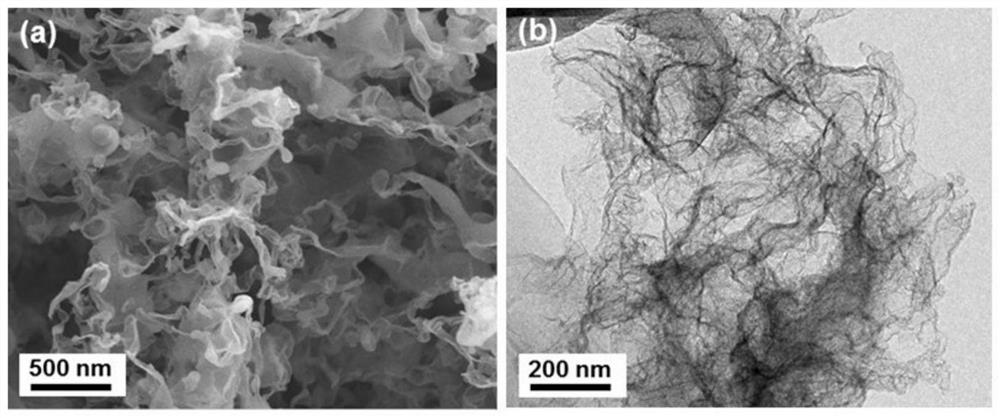

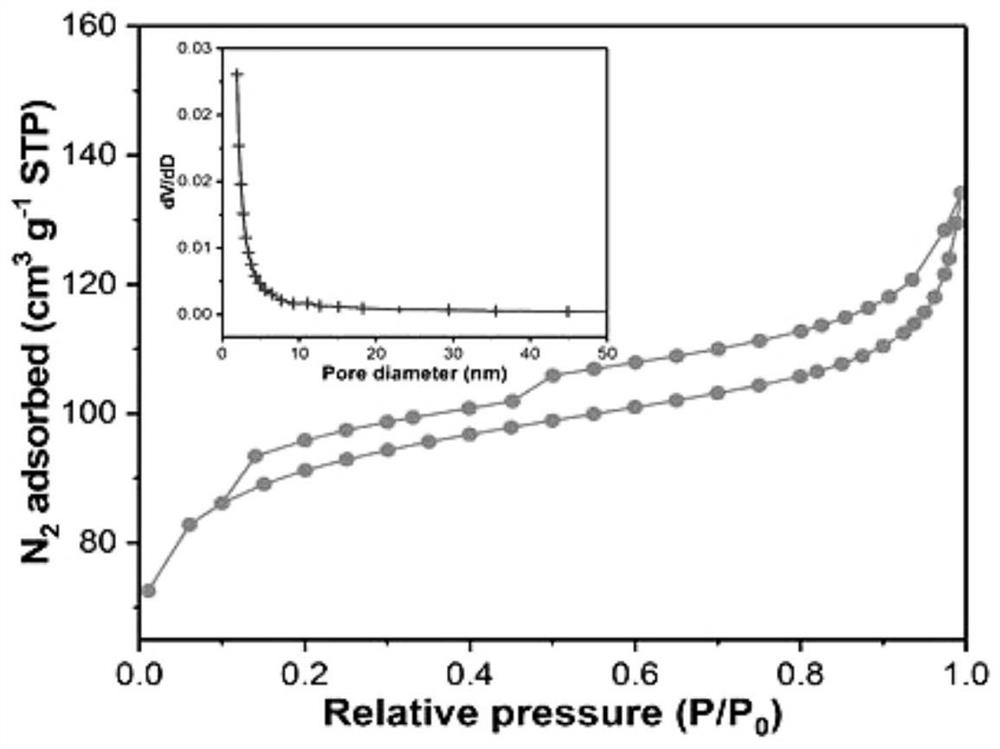

[0050] Present embodiment 1 provides a kind of preparation method of selenium, nitrogen co-doped biochar catalytic material, it comprises the following steps:

[0051] (1) Inoculate the Bacillus megaterium B-10 thallus stored on the LB slope into the LB liquid medium, and expand the culture for 12 hours at a temperature of 30° C. to obtain the seed liquid of Bacillus megaterium B-10; wherein the LB liquid culture The ratio of each component of the base is: peptone 10g, yeast powder 5g, sodium chloride 10g, distilled water 1L; the LB slope is based on the above formula by adding 15g / L agar;

[0052] (2) Na 2 SeO 3 Add to LB medium for bioreduction, add Na 2 SeO 3 The final concentration is 1.7g / L, and the bioreduction time is 24h. After reduction, centrifuge at 7,000rpm for 5min to obtain the Bio-Se bacterial precursor;

[0053] (3) adding 0.4 times the wet weight of the Bio-Se bacterial precursor to the obtained Bio-Se bacterial precursor ammonium chloride as a nitrogen so...

Embodiment 2

[0058] (1) Cultivate according to steps (1) and (2) in Example 1 to obtain the seed liquid of Bacillus megaterium B-10.

[0059] (2) Na 2 SeO 3 Add to sterile medium for bioreduction, add Na 2 SeO 3 The final concentration is 1g / L, and the bioreduction time is 12h. After reduction, centrifuge at 7,000rpm for 5min to obtain the Bio-Se bacterial precursor;

[0060] (3) Add ammonium chloride of 0.5 times the wet weight of the cell to the obtained Bio-Se bacterial precursor as a nitrogen source for mixing, and obtain a Se / N composite bacterial precursor after vacuum freeze-drying;

[0061] (4) The obtained Se / N composite bacterial precursor is subjected to a pyrolysis reaction under an inert atmosphere to obtain a selenium and nitrogen co-doped biochar catalytic material. The atmosphere of the pyrolysis treatment is a nitrogen atmosphere, and the temperature is 700 ° C. Carbonization The treatment time is 3h, and the heating rate is 5°C / min;

[0062] According to the step of ...

Embodiment 3

[0064] (1) Cultivate according to steps (1) and (2) in Example 1 to obtain the seed liquid of Bacillus megaterium B-10.

[0065] (2) Na 2 SeO 3 Add to sterile medium for bioreduction, add Na 2 SeO 3 The final concentration is 0.5g / L, and the bioreduction time is 12h. After reduction, centrifuge at 7,000rpm for 5min to obtain the Bio-Se bacterial precursor;

[0066] (3) Add ammonium chloride of 0.5 times the wet weight of the cell to the obtained Bio-Se bacterial precursor as a nitrogen source for mixing, and obtain a Se / N composite bacterial precursor after vacuum freeze-drying;

[0067] (4) The obtained Se / N composite bacterial precursor is subjected to a pyrolysis reaction under an inert atmosphere to obtain a selenium and nitrogen co-doped biochar catalytic material. The atmosphere of the pyrolysis treatment is a nitrogen atmosphere, and the temperature is 800 ° C. The treatment time is 2h, and the heating rate is 5°C / min;

[0068] According to the step of using the cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com