a cote 2 /mxene composite material and preparation method thereof

A technology of composite materials and preparation steps, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of inability to obtain rapid ion migration effect, electrode material crushing, and fast capacity decay, and achieve large transfer and ion adsorption area and Vacuum, prevention of agglomeration, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a CoTe 2 The preparation method of / MXene composite material, wherein, CoTe 2 For the synthesis method, please refer to:

[0045] "Xiao Peipei, Zhu Yongchun, Qian Yitai. Synthesis of patterned CoTe_2 ultrafine nanorod bundles by Te nanorod in situ template method with the assistance of CTAB[C].";

[0046] "China Instrument Functional Materials Society, Jiangsu University, "Functional Materials" journal, "Functional Materials Information" journal. Proceedings of the 2009 China Functional Materials Technology and Industry Forum.";

[0047] "Chinese Society of Instrument Functional Materials, Jiangsu University, "Functional Materials" Journal, "Functional Materials Information" Journal: Instrument Materials Branch of China Instrumentation Society, 2009:799-800.".

Embodiment 1

[0049] A CoTe 2 The preparation method of / MXene composite material, comprises the following steps:

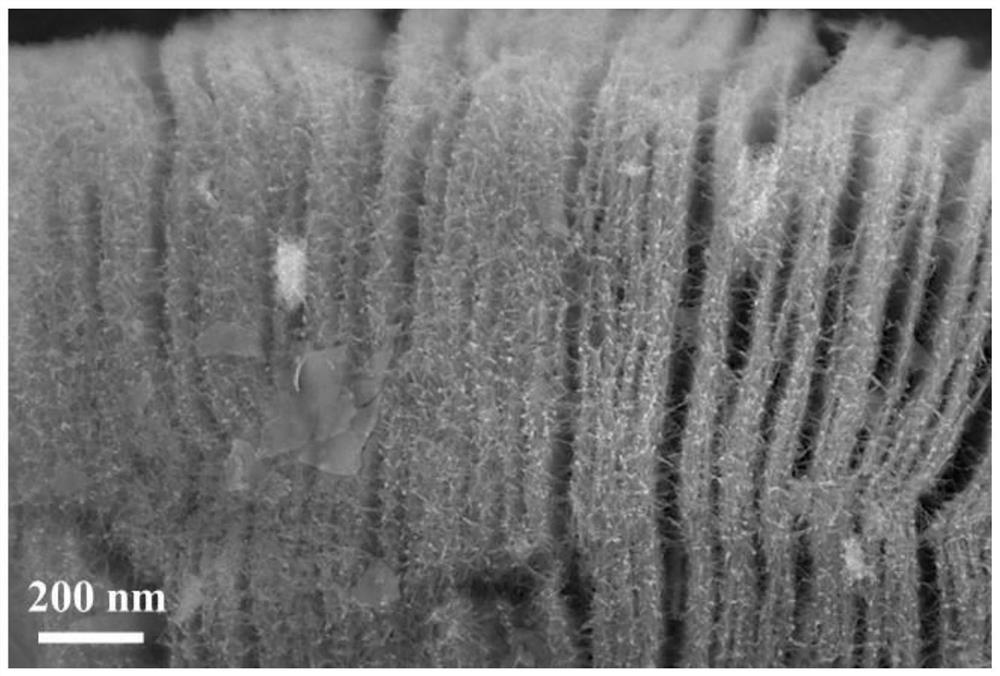

[0050] (1) Take 0.1mmol MXene (Ti 3 C 2 T x ) was added to N, N-dimethylformamide, configured into a 1 mg / ml dispersion, and stirred magnetically for 2 hours;

[0051] (2) Add 0.1mmol Co(NO 3 ) 2 ·6H 2 O and 0.1mmol urea were added in the dispersion liquid described in step (1), and stirred for 3 hours;

[0052] (3) Transfer the dispersion liquid obtained in step (2) into a reaction kettle with a capacity of 50ml, seal it, place it in an oven, heat it to 80°C, keep it warm for 8h, and then cool it to room temperature;

[0053] (4) Centrifuge the product obtained in step (3) for 5 minutes under the condition of 5000r / min, and wash the filter residue 3 times alternately with deionized water and absolute ethanol;

[0054] (5) Dry the centrifuged product obtained in step (4) in a vacuum drying oven at a drying temperature of 60°C and a drying time of 6 hours to obtain the p...

Embodiment 2

[0062] A CoTe 2 The preparation method of / MXene composite material, comprises the following steps:

[0063] (1) Take 0.2mmol MXene (Ti 3 C 2 T x ) was added to N, N-dimethylformamide, configured into a 5 mg / ml dispersion, and magnetically stirred for 4 hours;

[0064] (2) 0.2mmol Co(NO 3 ) 2 ·6H 2 O and 0.25mmol urea were added in the dispersion liquid described in step (1), and stirred for 9 hours;

[0065] (3) Transfer the dispersion liquid obtained in step (2) into a reactor with a capacity of 50ml, seal it, place it in an oven, heat it to 150°C, keep it warm for 15h, and then cool it to room temperature;

[0066] (4) Centrifuge the product obtained in step (3) for 8 minutes under the condition of 6000r / min, and wash the filter residue 3 times alternately with deionized water and absolute ethanol;

[0067] (5) Dry the centrifuged product obtained in step (4) in a vacuum drying oven at a drying temperature of 60°C and a drying time of 10 hours to obtain the precursor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com